1/200 Nichimo Hatsuzuki build

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Sunday, June 07, 2020 - 11:46 AM UTC

Quoted Text

Very nice start on the bridge detail Tim,

Will add a nice amount of depth, are you going to leave the doors into the wheelhouse open?

Cheers

Si

Thanks Si. Yes, I'm building more details to add in the wheelhouse, but it will be pretty hard to see in there through those small bridge windows... so open doors should help!

#306

Victoria, Australia

Joined: June 27, 2010

KitMaker: 3,959 posts

Model Shipwrights: 2,777 posts

Posted: Monday, June 08, 2020 - 11:11 PM UTC

Love the level of detail you're adding to this model, Tim

Stay home and build models!

In 1/72

Gloster Gladiator MkII for the Bi-planes Campaign

In 1/350

Airfix 1:350 Type 45 Destroyer

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Wednesday, June 10, 2020 - 02:21 AM UTC

Quoted Text

Love the level of detail you're adding to this model, Tim

Thanks Russ. Adding extra details is one of my favorite aspects of modeling... although I seem to be going off the rails at the moment adding components that will be difficult to see inside the pilothouse!

Kagero Publishing’s The Japanese Destroyer Akizuki by Mariusz Motyka and Lukasz Stach (ISBN 978-83-62878-69-7) has a beautiful rendering of the navigation bridge interior.

Following this and the images in the Kojinsha Maru Mechanic Mechanism of Japanese Destroyers book, I built up Hatsuzuki’s type 90 magnetic compass and helm from plastic sheet and sprue scrap. The wheel is an etched brass part from Gold Medal Models 1/350 Emden/Dresden set, and the quadrantal correctors (the iron spheres fitted in brackets on either side of the binnacle) began life as the rollerballs in ball point pens.

I also built up simple gyrocompass, repeater, and engine order telegraph assemblies.

Test fitted in place, they show just how crowded the navigation bridges were on these small ships!

Virginia, United States

Joined: May 18, 2008

KitMaker: 496 posts

Model Shipwrights: 404 posts

Posted: Wednesday, June 10, 2020 - 02:54 AM UTC

Lookin' awesome, Mr. R.!!

#453

Texas, United States

Joined: August 28, 2016

KitMaker: 1,925 posts

Model Shipwrights: 1,298 posts

Posted: Wednesday, June 10, 2020 - 05:11 AM UTC

Tim,

Nice job upgrading the navigation bridge. That compass and wheel assembly looks bigger than some of your ships you built...LOL.

Mark

England - South East, United Kingdom

Joined: March 01, 2010

KitMaker: 7,078 posts

Model Shipwrights: 6,649 posts

Posted: Wednesday, June 10, 2020 - 06:17 AM UTC

What the guys said,

the binnacle is a very nice piece of work, the wheelhouse is looking nice busy.

very much enjoying following along.

Cheers

Si

Washington, United States

Joined: August 03, 2008

KitMaker: 436 posts

Model Shipwrights: 31 posts

Posted: Wednesday, June 10, 2020 - 10:38 AM UTC

Tim,

At least you are giving the people that really look at the model something to discover. Besides, there is always the old saying "At least I know it is there!"....

Fantastic build, and I am definitely enjoying following you through it....

Bob

#513

Alabama, United States

Joined: March 28, 2006

KitMaker: 554 posts

Model Shipwrights: 219 posts

Posted: Wednesday, June 10, 2020 - 01:28 PM UTC

Awesome detail work, as always Obiwan. The force is truly with you.

#424

Queensland, Australia

Joined: April 23, 2015

KitMaker: 4,648 posts

Model Shipwrights: 249 posts

Posted: Wednesday, June 10, 2020 - 10:59 PM UTC

That's awesome, Tim.But I love seeing it, too.

"Artillery adds dignity, to what would otherwise be an ugly brawl."

Frederick The Great

New Jersey, United States

Joined: February 06, 2015

KitMaker: 1,098 posts

Model Shipwrights: 34 posts

Posted: Thursday, June 11, 2020 - 03:09 PM UTC

Very impressive Tim ! Really enjoy watching this one !

#345

Niedersachsen, Germany

Joined: August 22, 2011

KitMaker: 1,835 posts

Model Shipwrights: 1,832 posts

Posted: Saturday, June 13, 2020 - 05:39 AM UTC

Tim,

that's absolutely stunning!! Seeing the master of micro modeling applying his skill to a 1/200 model...unbelievable detail. I love the way you are approaching the pilot house with all the interior!

Cheers

Jan

Queensland, Australia

Joined: May 20, 2010

KitMaker: 1,230 posts

Model Shipwrights: 1,212 posts

Posted: Saturday, June 13, 2020 - 05:30 PM UTC

It's good to see that I am not the only one who goes nuts adding things that may not be seen. You attention to detail is fantastic along with your Skills Mate. Love it so far.....Cheers mark

If I was your Wife I would Poison your Tea

If I was your Husband, I would drink it.

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Monday, June 15, 2020 - 02:16 AM UTC

Thanks everyone, I really do appreciate your kind comments! It is good to hear that I'm not entirely alone in my crazy micro world...

Here's hoping that at least SOME of this stuff will be visible through those tiny bridge windows... but that's a worry for another day.

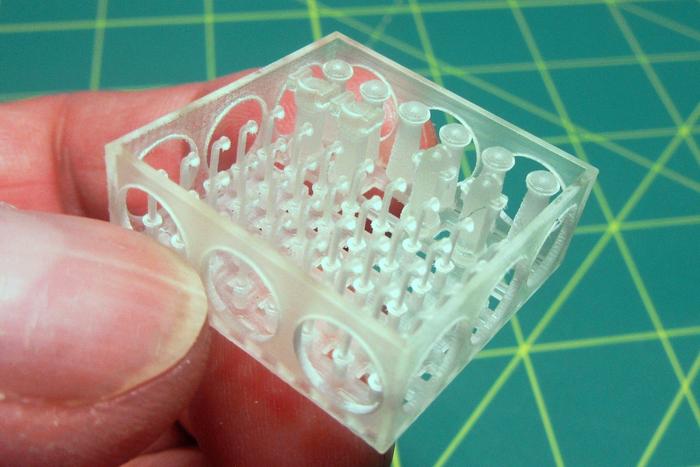

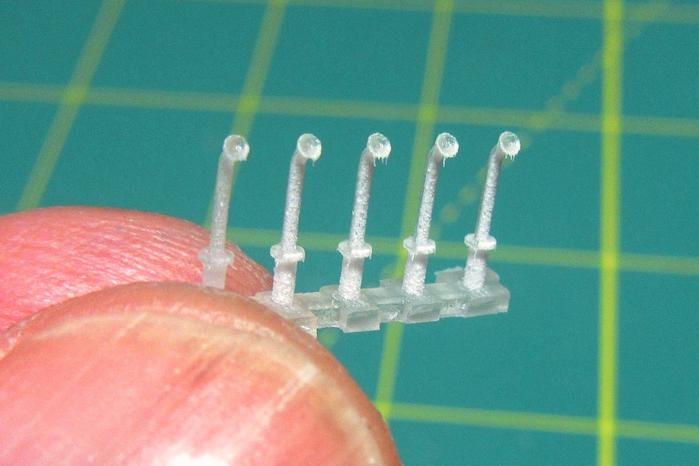

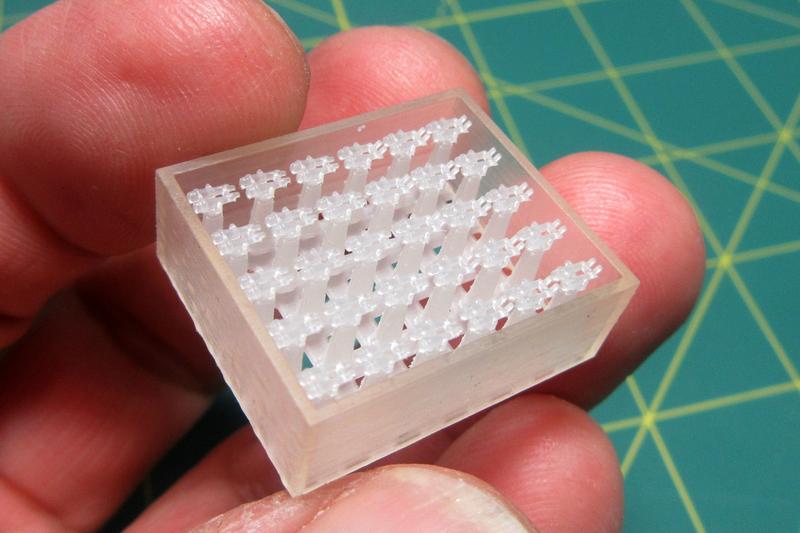

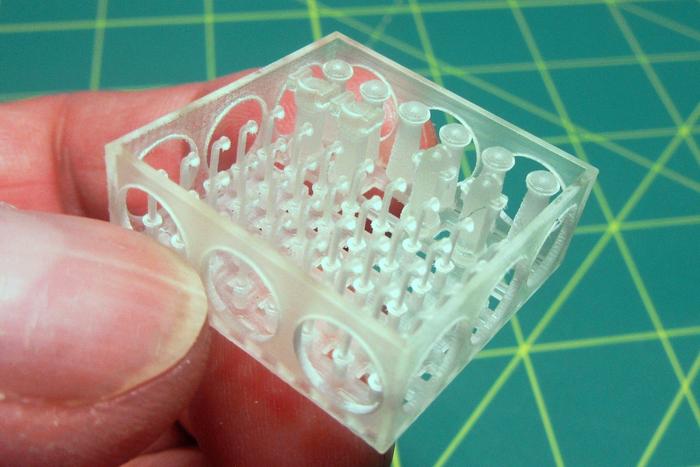

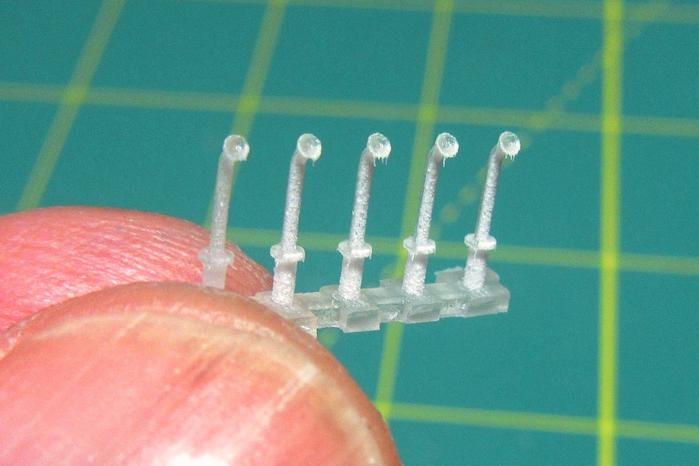

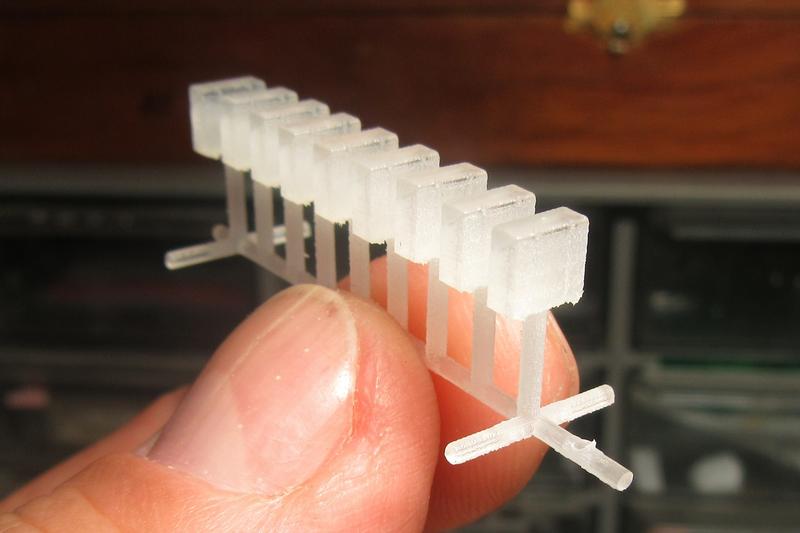

For now, after I began scratchbuilding the Hatsuzuki’s bridge interior I found that there are a number of 1/200 scale 3D printed Imperial Japanese Navy navigation bridge parts commercially available as well.

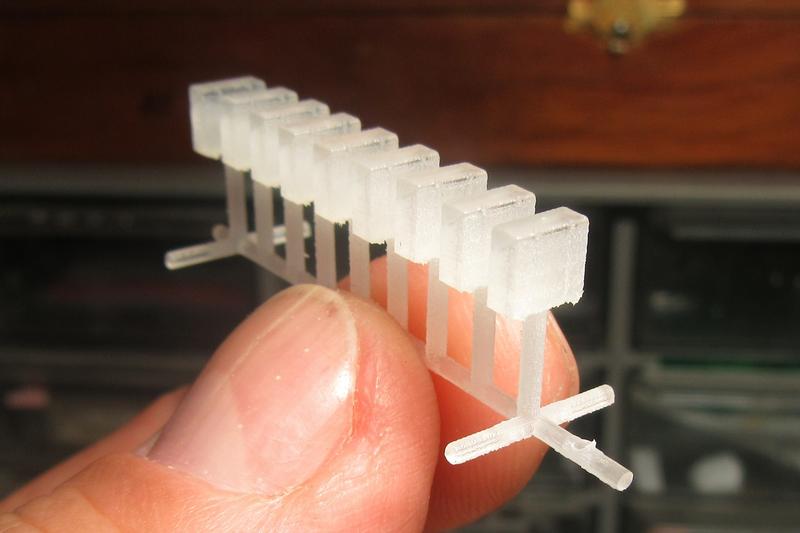

I’ll still use my scratchbuilt components, but the bridge will now also sport Shapeways 3D-printed IJN gyrocompass repeaters and voice tubes by

ModelShipJP (Shingo Nakamura).

These parts are beautifully designed, although the Shapeways production standard of “Smoothest Fine Detail Plastic” is inferior to the Model Monkey 3D-resin gas cylinder parts I had used earlier. Still, the frost-like surfaces of the parts can be smoothed with steel wool, and once painted they will do a lot to busy-up the already crowded navigation bridge.

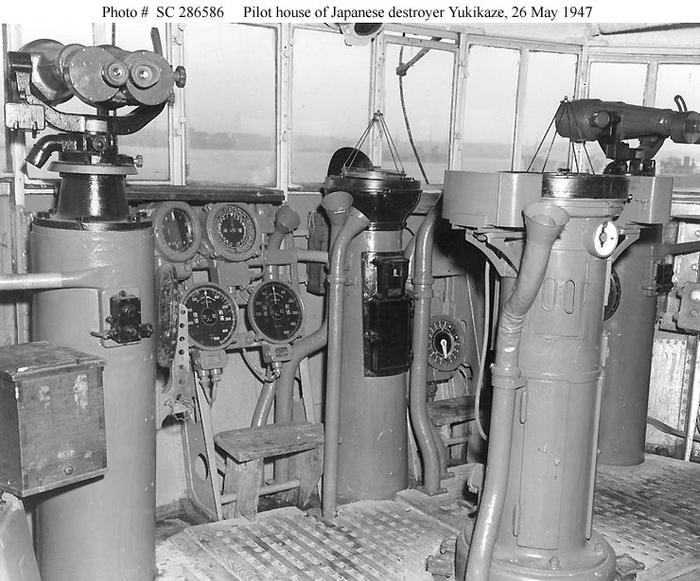

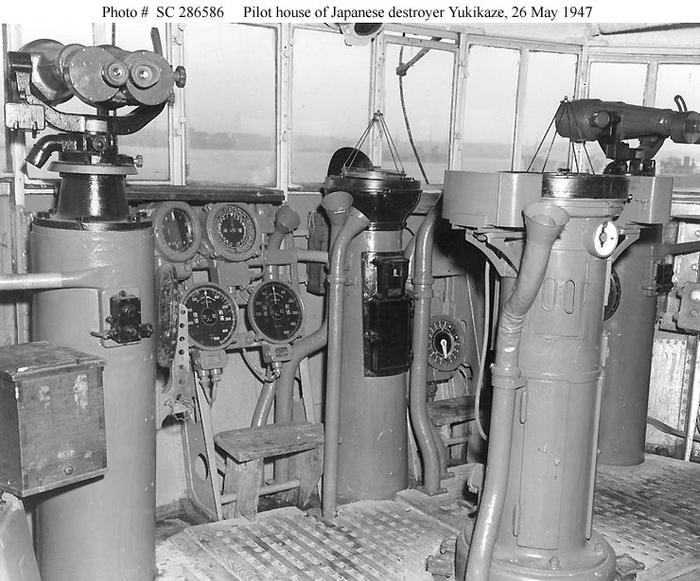

This postwar picture of the former IJN Yukikaze’s bridge gives a sense of how crammed with equipment these WWII destroyer pilothouses were.

#424

Queensland, Australia

Joined: April 23, 2015

KitMaker: 4,648 posts

Model Shipwrights: 249 posts

Posted: Monday, June 15, 2020 - 08:40 AM UTC

Love those tiny details, Tim. Surprised there is so much out there.

"Artillery adds dignity, to what would otherwise be an ugly brawl."

Frederick The Great

#453

Texas, United States

Joined: August 28, 2016

KitMaker: 1,925 posts

Model Shipwrights: 1,298 posts

Posted: Tuesday, June 16, 2020 - 12:01 AM UTC

Tim,

Those 3D models will give the PE and Resin market a run for their money. I hope Shapeway's increase their offering of 3D products for Japanese ships and Model Monkey enhances their offering for British and Japanese ships.

Mark

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Tuesday, June 16, 2020 - 02:18 AM UTC

Quoted Text

Love those tiny details, Tim. Surprised there is so much out there.

Quoted Text

Tim, Those 3D models will give the PE and Resin market a run for their money. I hope Shapeway's increase their offering of 3D products for Japanese ships and Model Monkey enhances their offering for British and Japanese ships.

Mark

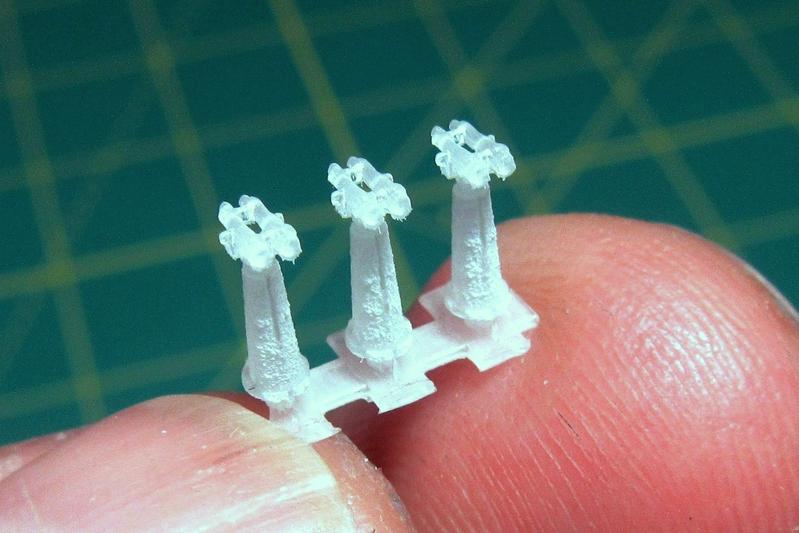

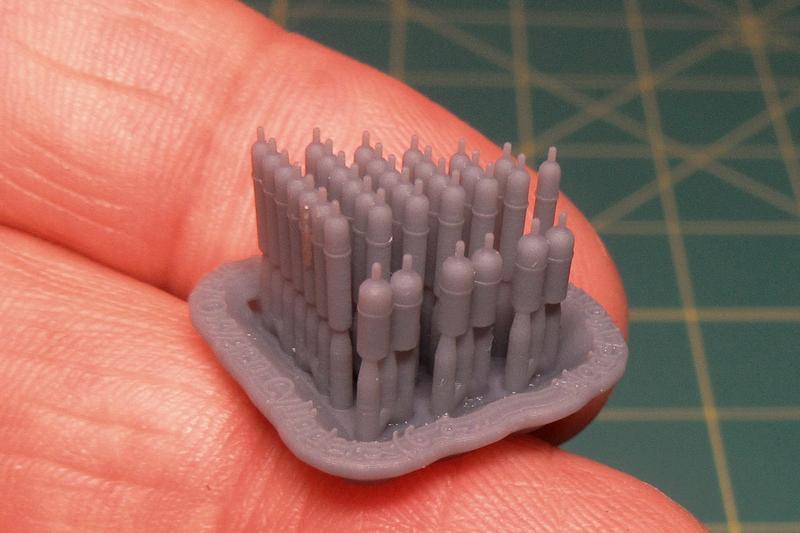

Though the parts are expensive and fussy to work with, I agree, 3D printing technology offers a great new option to fill gaps not served by traditional etched metal or poured resin aftermarket. The range of potential products is limitless, and the detail possible far exceeds what can be economically produced by traditional resin casting.

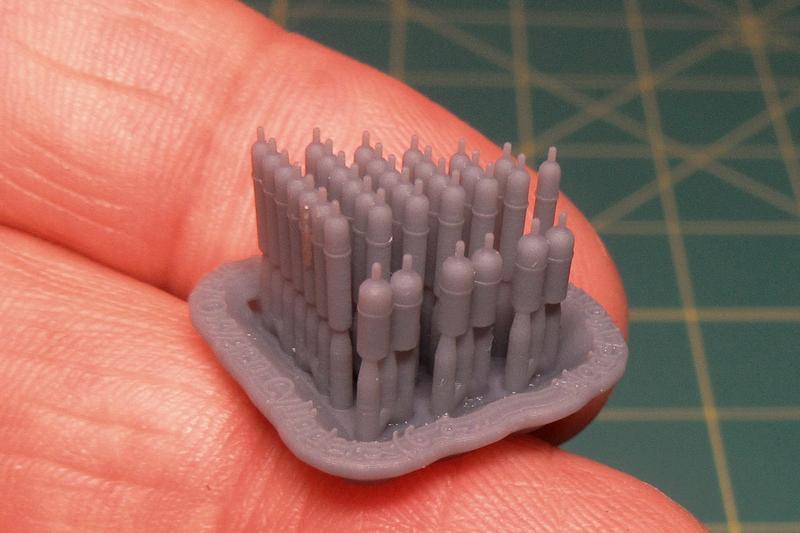

I hope in future more products are produced using Model Monkey’s gray resin process, like these oxygen and acetylene cylinders I applied earlier on the funnel:

Model Monkey employs a different technology than that used by other 3D-printing companies like Shapeways; the gray resin is not nylon but rather an acrylate-based plastic chemically similar to Plexiglas. The parts print up much cleaner and sharper, and the solid gray is simpler to work with than the semi-clear material Shapeways uses.

Ultimately, though, even the lesser quality Shapeways parts offer tremendous new opportunities to go nuts with detailing – and that’s really the point, right?!

#491

Missouri, United States

Joined: April 06, 2016

KitMaker: 602 posts

Model Shipwrights: 349 posts

Posted: Tuesday, June 16, 2020 - 02:43 AM UTC

Quoted Text

Model Monkey employs a different technology than that used by other 3D-printing companies like Shapeways; the gray resin is not nylon but rather an acrylate-based plastic chemically similar to Plexiglas. The parts print up much cleaner and sharper, and the solid gray is simpler to work with than the semi-clear material Shapeways uses.

I will never not have anything good to say about Model Monkey and their products. They are excellent and the company is now in possession of quite a lot of my $$$

Currently working on: Multiple Campaigns :P

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Saturday, June 20, 2020 - 10:56 AM UTC

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

Model Shipwrights: 173 posts

Posted: Saturday, June 20, 2020 - 11:06 AM UTC

Tim, How are you cleaning those parts? I think I read a while back that the roughness of these “printed” parts can be cleaned off using a tiny brush and some paint or lacquer thinner if you’re careful. Have you tried that?

VR, Russ

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Saturday, June 20, 2020 - 11:49 AM UTC

Quoted Text

Tim, How are you cleaning those parts? I think I read a while back that the roughness of these “printed” parts can be cleaned off using a tiny brush and some paint or lacquer thinner if you’re careful. Have you tried that?

VR, Russ

Naw, I was afraid of melting the tiny parts with solvent, so I limited my tools to fine steel wool and harsh language! Actually, with a bit of care and patience they do clean up well enough.

England - South East, United Kingdom

Joined: March 01, 2010

KitMaker: 7,078 posts

Model Shipwrights: 6,649 posts

Posted: Saturday, June 20, 2020 - 09:34 PM UTC

The bridge layout looks right with the parts test fitted Tim, Feels like you could walk on to it and take the con.

Cheers

Si

#453

Texas, United States

Joined: August 28, 2016

KitMaker: 1,925 posts

Model Shipwrights: 1,298 posts

Posted: Sunday, June 21, 2020 - 08:22 AM UTC

Tim,

I believe the material that Shapeway uses requires to be cure by exposing the material in the sun for a couple of hours, did you do that or am I wrong about the curing in the sun. I was wondering if that could had been why they were brittle. So far I only used their mushroom vents and I had no problem removing them from the base or smoothing out the rough spots.

Mark

#424

Queensland, Australia

Joined: April 23, 2015

KitMaker: 4,648 posts

Model Shipwrights: 249 posts

Posted: Sunday, June 21, 2020 - 12:58 PM UTC

Bridge looks awesome, Tim!

"Artillery adds dignity, to what would otherwise be an ugly brawl."

Frederick The Great

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Monday, June 22, 2020 - 04:00 AM UTC

Si and Gary, thanks! Those 3D printed detail parts are pretty awesome!

TimReynaga

Associate Editor

Associate EditorCalifornia, United States

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Monday, June 22, 2020 - 04:00 AM UTC

Quoted Text

Tim,

I believe the material that Shapeway uses requires to be cure by exposing the material in the sun for a couple of hours, did you do that or am I wrong about the curing in the sun. I was wondering if that could had been why they were brittle. So far I only used their mushroom vents and I had no problem removing them from the base or smoothing out the rough spots.

Mark

Mark,

I tried working the Shapeways parts as they arrived, but they were incompletely cured and so slightly gooey. Exposing them to sunlight as Shapeways recommended did harden them up nicely, but the fully cured material is inherently brittle. Cleaning them up actually wasn’t really all that difficult, just more fussy than traditional molded polystyrene plastic or the Model Monkey style acrylate-based gray resin 3D printed parts. The upshot is that although not perfect, these parts offer the possibility of huge detail improvements with less effort than scratchbuilding... so really, I can’t complain!