So as you guessed, the LM2500 is a jet engine. This could cause a few problem on board a ship, noise, heat, and fire hazards being foremost. These problems are mostly solved by a unique structure, called simply the enclosure. It is a large metal box that the engine is mounted in. Along with the engine are the power turbine and the fire suppression system. The fire system works off of light and heat sensors. If a fire is detected the engine is put into an emergency stop, fuel, air, and ventilation are shut off. Then the whole enclosure is flooded with CO2. The enclosure is a rather interesting piece of equipment and make gas turbine propulsion possible. One end of the box is hooked up to the intake plenum, the opposite end is connected to the exhaust, and the third hole allows the power turbine to connect to the main reduction gear(MRG).

Again I am going to stay away from as much of the technical jargon as I can. When going through the Navies Gas Turbine school you get flooded with all the technical stuff in 14 weeks. Then you live it on board your ship for the next few years, so it becomes part of your vocabulary. Not only does the Navy use turbines for propulsion they also use them for power generation. The two engines have the same lay out, but different terminology. So learning the two turbines can be confusing, but once you remember the differences it gets easier.

The principal of operation is straight forward. Remember taking a balloon and blowing it up then letting it go? A turbine works something like that, except it compresses the air by its self then pushes it out its exhaust with great force. Several laws of physics come into play in a gas turbines operation, Newton, Charles, Boyle, and Pascal. But you don't want to read about those.

The navy uses gas turbines for several reason. First they are easy to chance if one breaks. Just install rail inside the ships intake and putt it out. Then slide a new one back in, hook it up, and your ready. Next is the ships can be ready to get underway in about 5 minutes. Steam ships can take 24 hours to build up pressure in order to leave port. If the ships in Pearl Harbor were gas turbine ship, they might have been able to get out of the harbor. Also the engines are lighter than boilers and easier to operate.

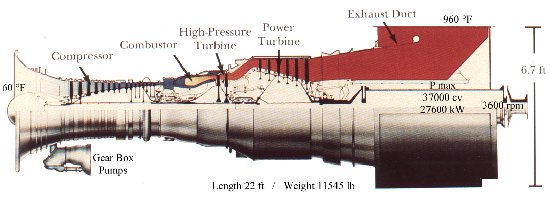

So how does a turbine work? It draws air into the forward section, or compressor. The air is compressed as it is forced into the combustion section. In this section the air looses pressure but gain volume, heat, and velocity. In the very small space just about all those laws of physics I mentioned before come into play. It really confuses a person, but it works. The hot gases are then used for different things at this point. 70% of the air flow is used to center and cool the flame, while the remaining 30% is used for the flame itself. Also at different stages of the compressor “bleed air” is taken off the engine and used for other things around the ship. 3000 Psi air is stored in high pressure flasks, air is used for the Prairie/Masker system, and other systems around the engine room.

After the hot high pressure air leaves to combustion chamber it blows across the high pressure turbine. This turbine is connected to the compressor section and in turn drives the engine. For those gear heads out there it works very much like a turbo on a car or truck. The exhaust now travels into the power turbine section of the enclosure. The power turbine is simply a set of blades that rotates up to 3600 rpm. The turbine is also connected to a flexible coupling shaft which runs to the MRG. The MRG takes the high rpm from the turbine and reduces it to a usable speed for the ship. The exhaust runs up the stack and out into the atmosphere.

The MRG itself is a monster piece of equipment. It is a locked train, double reduction, double helical, double input, single output system. More than any other piece of equipment on the ship, this is piece of equipment is of major importance. To replace one is more than a major task and would put a ship out of operation for a very long time. The access panels on the MRG are locked and only the Chief Engineer has the keys. The keys are locked in his safe at all times.

Since I came this far I will run through the shaft as well. The shaft on a destroyer like I was on is hollow. Down the middle of the shaft runs a set of tubes carrying hydraulic oil and air to the screw. The air is used in the Prairie system and the oil is used to rotate the blades of the screw. The shaft only rotates in one direction, so to make the ship reverse, you can change the pitch on the blades of the screw. They go from full ahead to 50% back. The shaft is supported by large bearings along its path and rotates around 125 rpm. We painted stripes around the shaft in MER1(main engine room 1) and numbered them. At the start of a cruise we would bet on which number would be the one at the pinter when we pulled back into port in Norfolk. Of course this was unofficial and not endorsed by any officers that may have taken part in such and activity.

The enclosure is a rather crammed unit. It holds the engine and gives you just enough room to try and move around inside it. I am 6'5” and it was really tight for me. The lighting inside is not the greatest. You really have to watch out where you put your hands and feet so you don't break anything or snag anything on the engine.