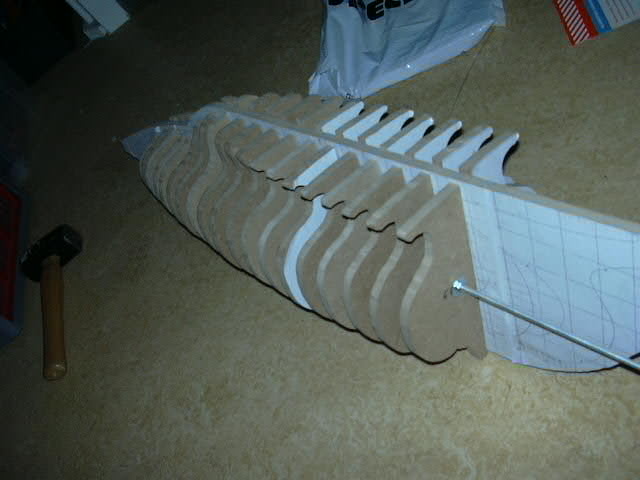

just a progress report of my scratchbuild.

it's a model of a rather obscure WWII italian midget submarine.

the model will be remotely controlled and capable of diving (at the least), but

currently I'm in the molding and laminating stage.

from the plans ( a very friendly Italian gentleman obtained them for me)

I cut the ribs

then filled with PU foam.

Then a coat of polyester and a lot of sanding.

Then I decided to pay one of the two remaining 1:1 versions of the CB

a visit and took a train to Zagreb. one day and night to get there, a full day to

photograph any and all rivets on this boat and then again a night and a day back to home. The people in Zagreb were very friendly, showed me even the inside of this boat, and the plans turned out to be less than accurate.

after that I built the master of the tower structure first, as a small scale test

for the laminating process. I'll skip that in this short post.

Because of the challenging shape of the boat, a polyester mold would not

allow the original or the hulls to escape it. So I built a mold consisting of

a soft rubber layer supported by a hard shell. The rubber skin can be lifted

from the shell and then the hull can be peeled out of the rubber.

This required a molding board. Note that you can fine-tune the height

of the parting board.

the mold consists of a left and right half.

I built a wooden box around the model and RTV skin and

created a hard backing for the soft rubber with

reinforced plaster, simply by pouring it into the wooden box.

A bit of PE foam was used to top off the box (and save weight), then

the box was nailed shut.

after that the whole construct was turned upside down

and the model was pulled from the mold(-half), which now sat neatly in

a wooden crate. if only the wet plaster had not warped the planks...

just now I laminated a hull into the mold. work on the other mold half will

start shortly.

all this took one and a half year, more details about this process

can be found

on this site

I posted a walkaround of the Zagreb vessel a while back :

https://modelshipwrights.kitmaker.net//features/1433

Regards,

Ronald van Aalst