Update for the stand hardware.

A solid "no shake" stand. I ground down the male threads on the Brass Riser. Fitted and CAed the smaller brass tube to that end of the riser. The larger brass tube is CAed into the White Bic plastic pen........which is very solidly attached to the inside of the hull.

You will note from the photo that I had thoughts of drilling out the Brass Riser and either slipping in the smaller tube or a long bolt. Went through several brass risers in this testing process.

I THINK I have something that will be solid, yet allow me to remove the hull from the stand. If i had not wanted to make the stand removable i would have omitted the smaller tube. It would then have fit onto the male elnd of the riser.

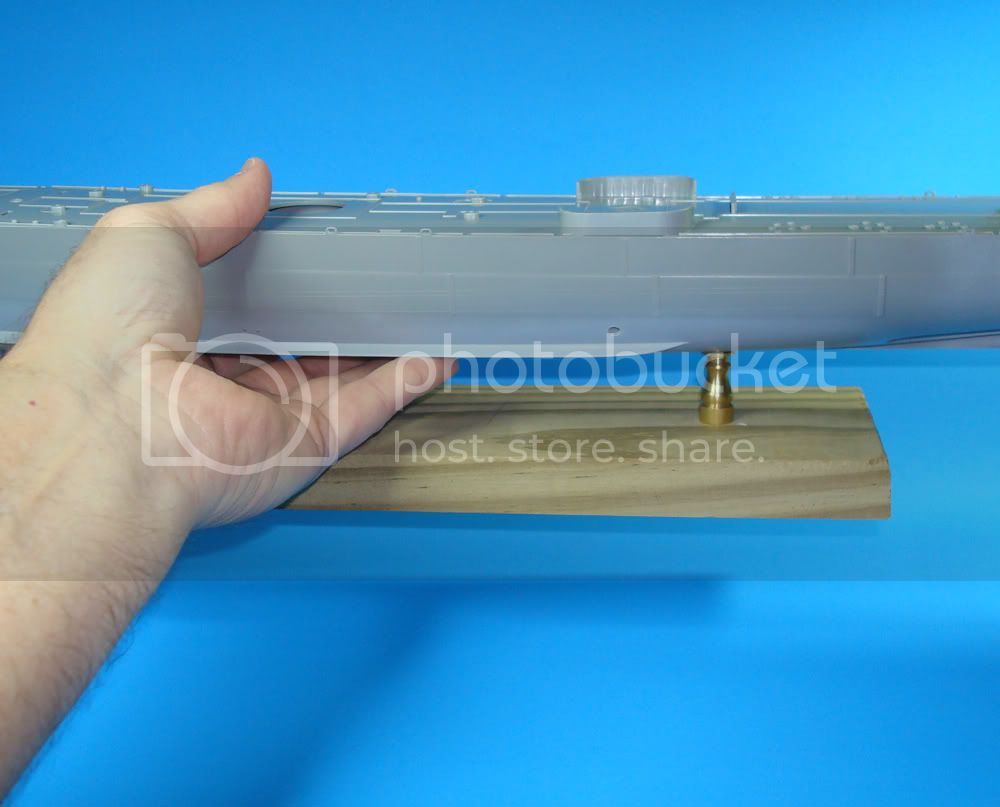

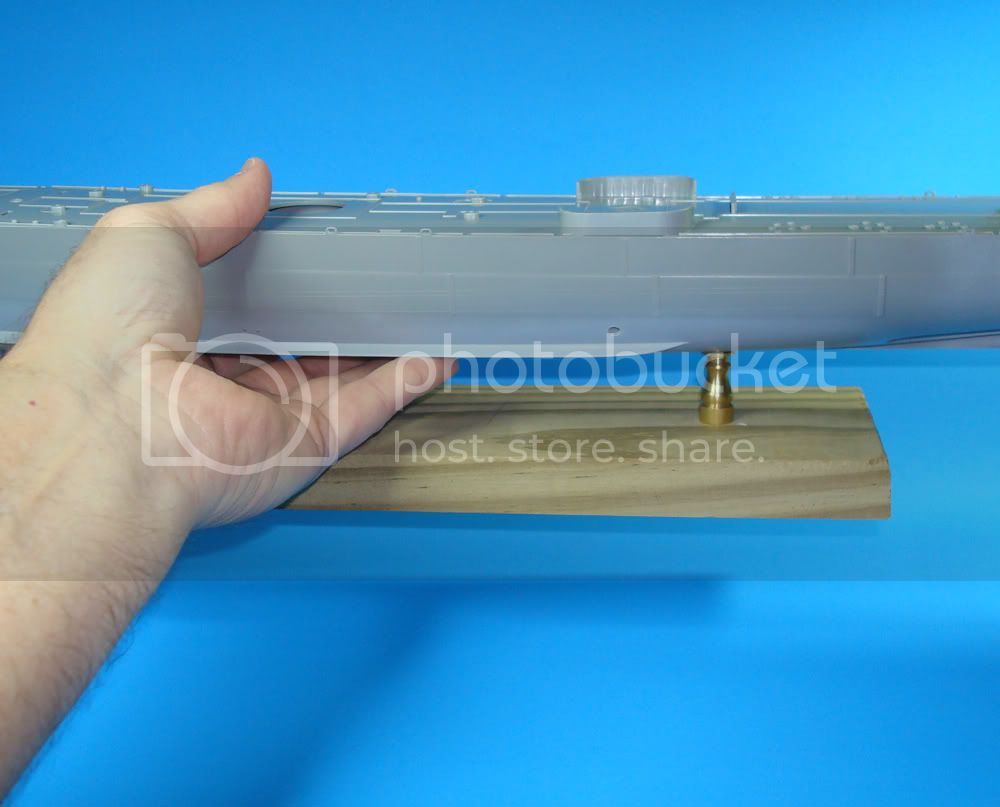

OK, one last "Stand" photo and I'm back to work on the ship. I have attached a "Temporary" build stand. The display stand later. It's not hard to see the belly intakes sitting elevated like this. No brass parts have been CAed as of yet, but the photo showing it being lifted shows that the fit is tight and it's not really going anywhere. I had to cut down my bolts as I recessed the heads into the wood base.

This stand/base has taken me an abnormally long time since I've never made a ship stand before. At least now i have the steps down. Next ones will be much simpler.

I'm ready to get back to the ship now..........

Regards

Steve