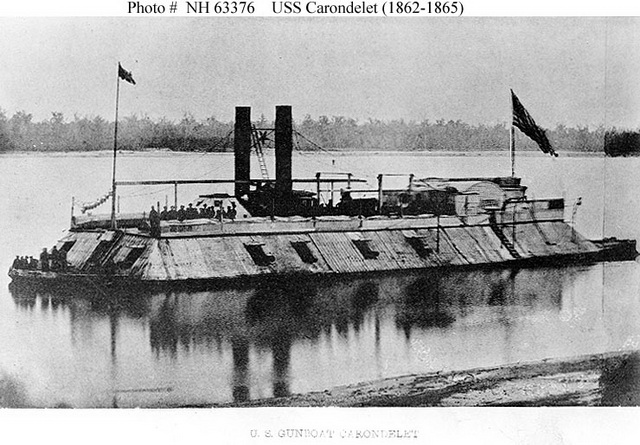

This build is of the USS Carondelet. For some specifics about the City Class gunboats, of which she was a member, and a bit of history on Carondelet, visit my website above. The build will be mostly of styrene, but I will use cast resin parts and brass where I can get away with it.

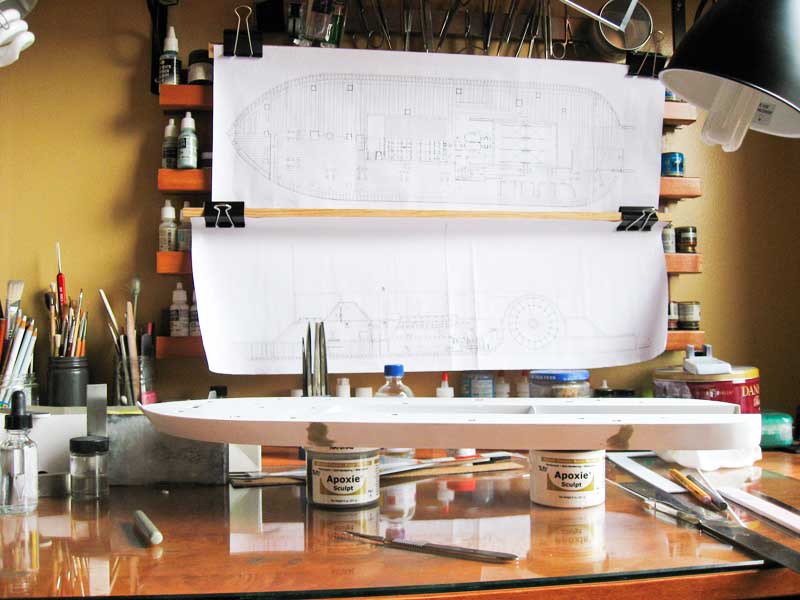

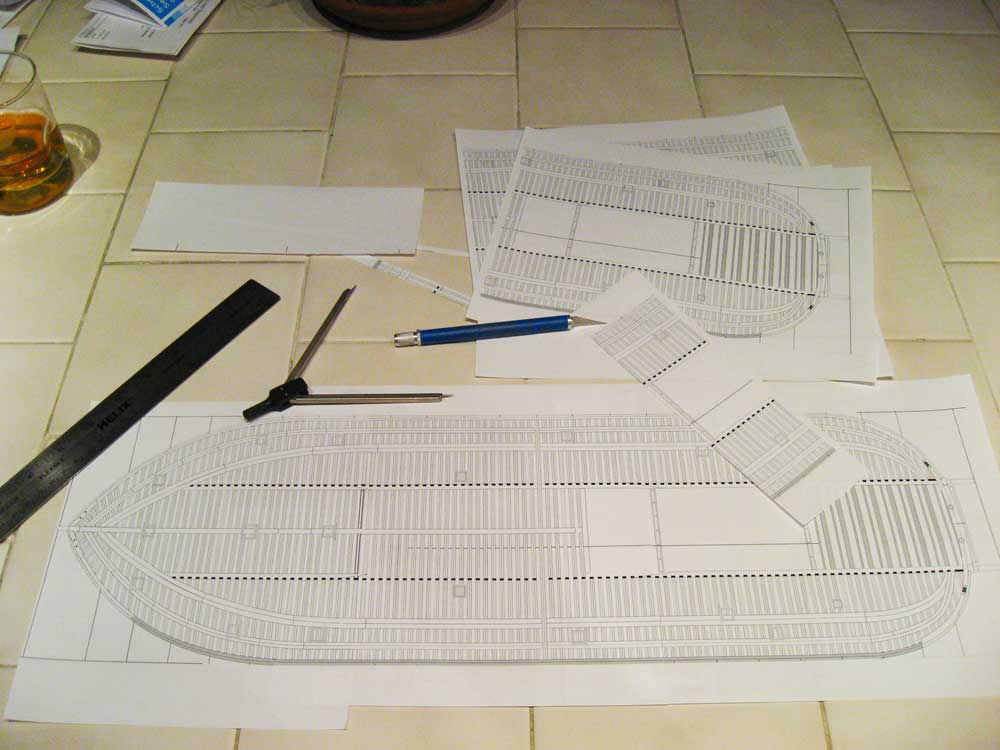

Anyway... first off is the overhead plan. I scanned the plans I'm using into Photoshop, sized them, printed them out, taped them together, and used contact adhesive to attach them to .060 sheet styrene (~1.5mm).

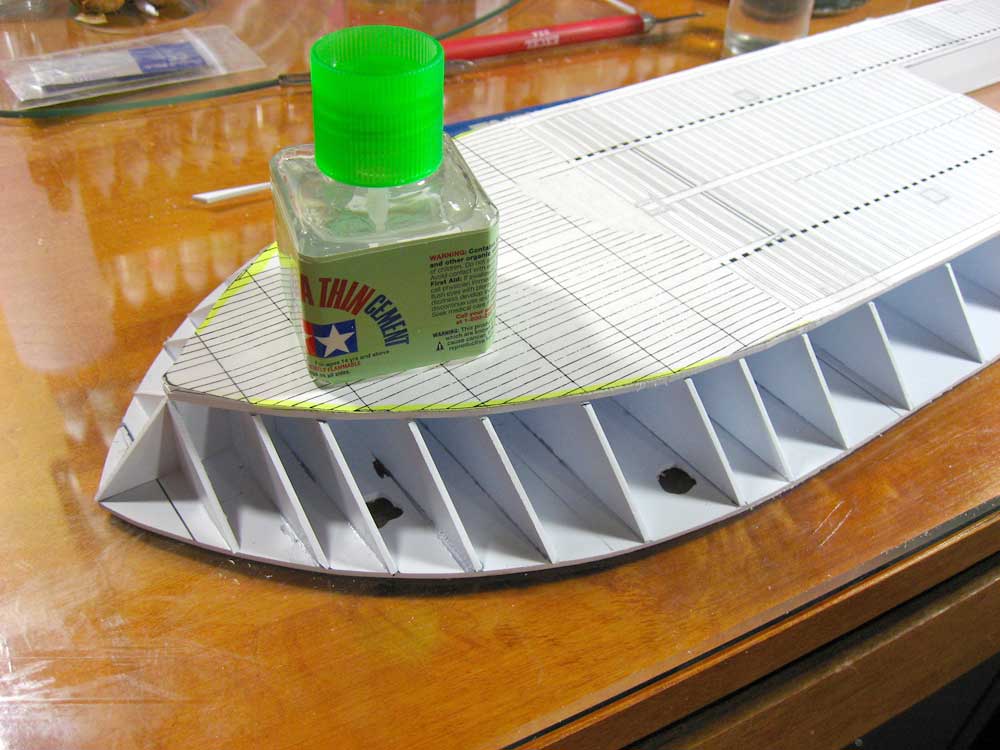

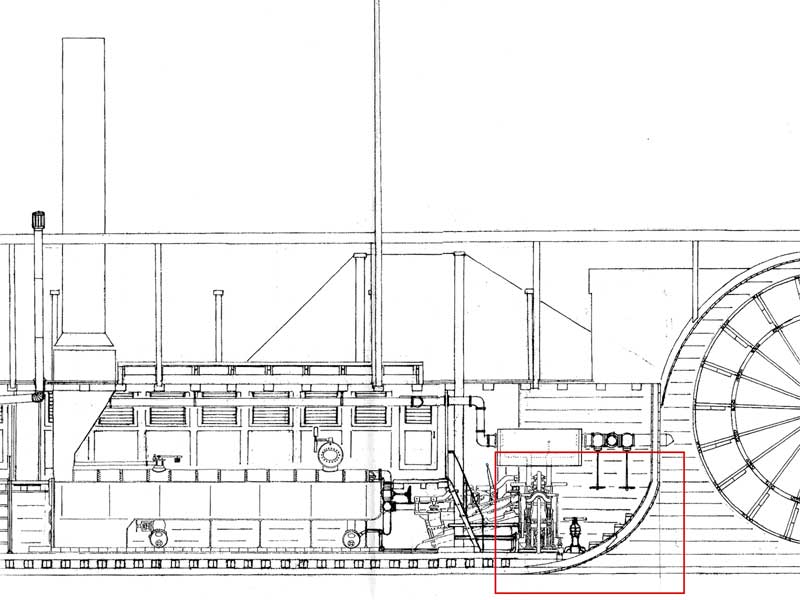

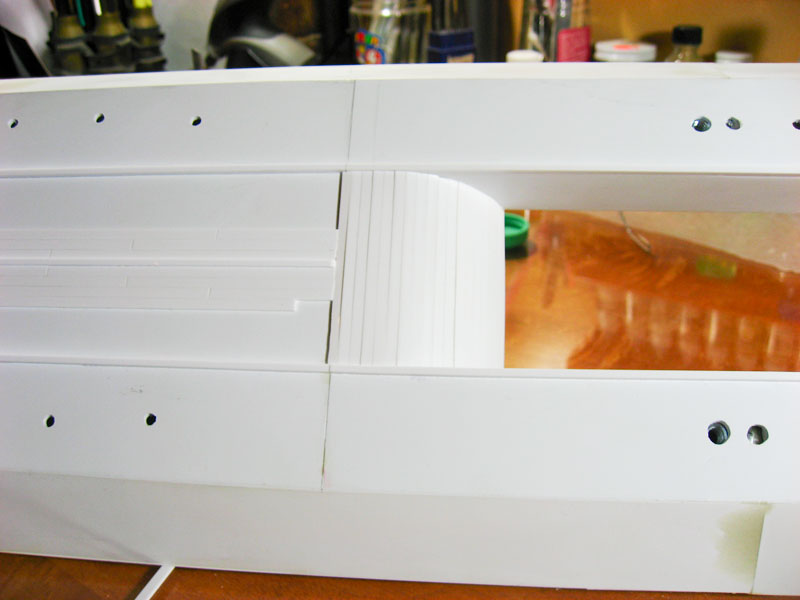

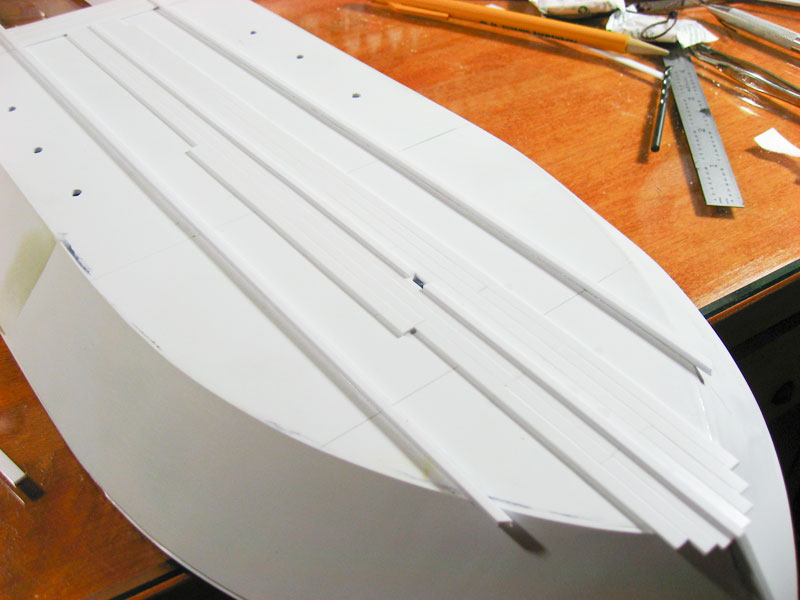

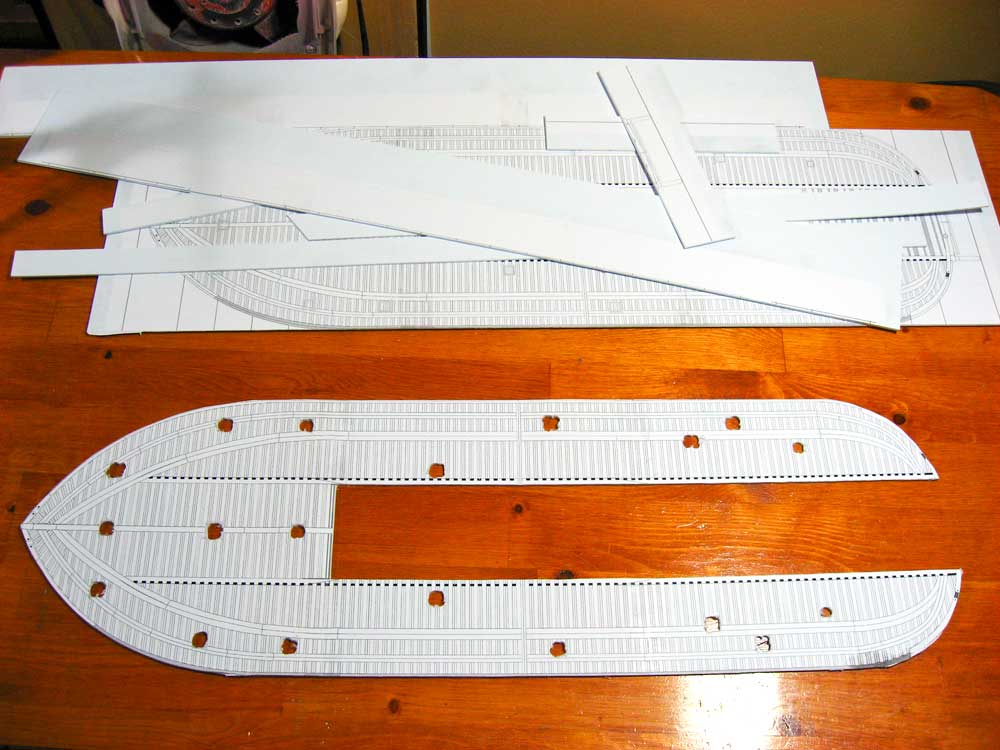

Next comes the cutting. Here's the main deck. The large channel down the middle of it is for the paddle wheel. These City Class boats were of a mid-wheel design, utilizing the casemate and hull thickness for protection of the wheel assembly. The holes drilled in the deck are for the passages down into the lower hull where they stored ammunition, ropes, stores, etc. I drilled them round here because it was easier then cutting square holes in such thick styrene. When I plank the decks these openings will be squared off.

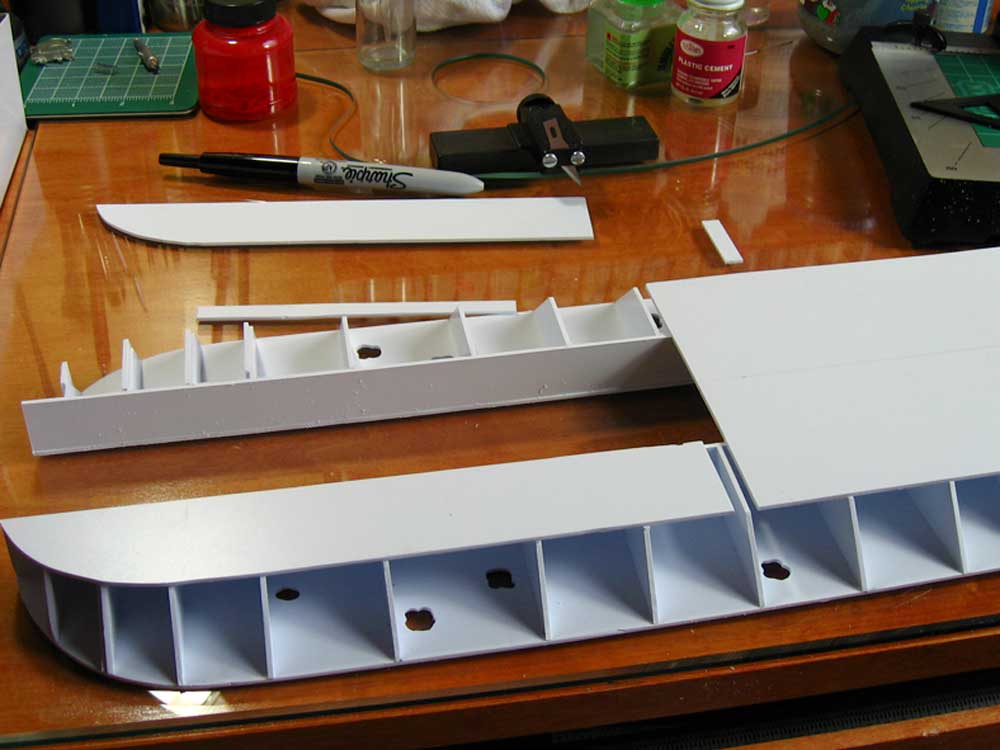

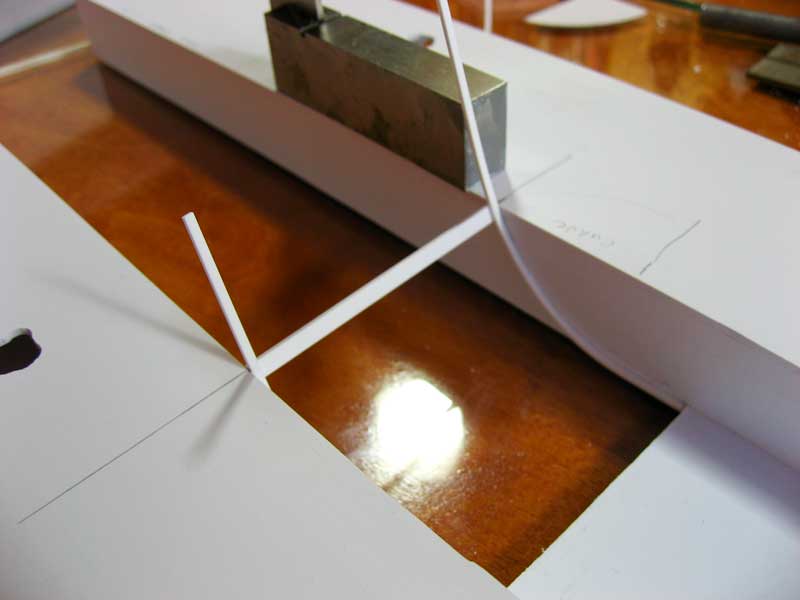

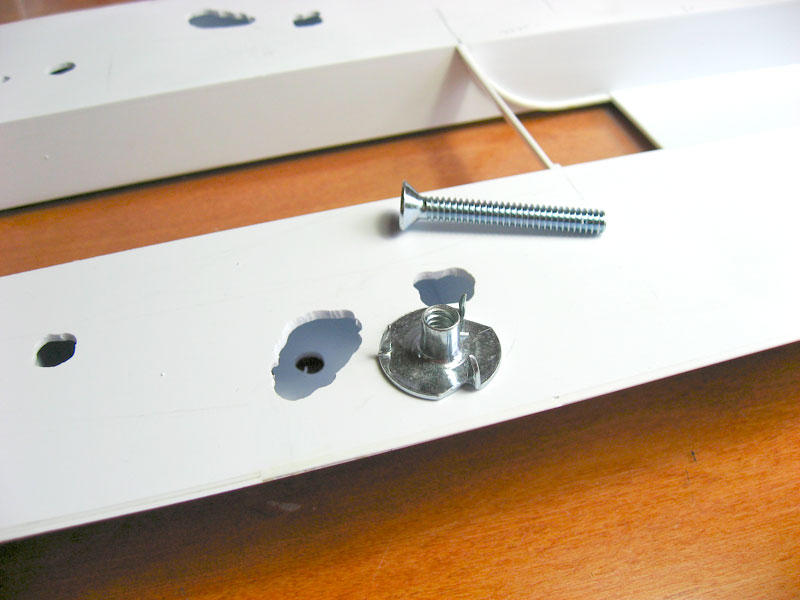

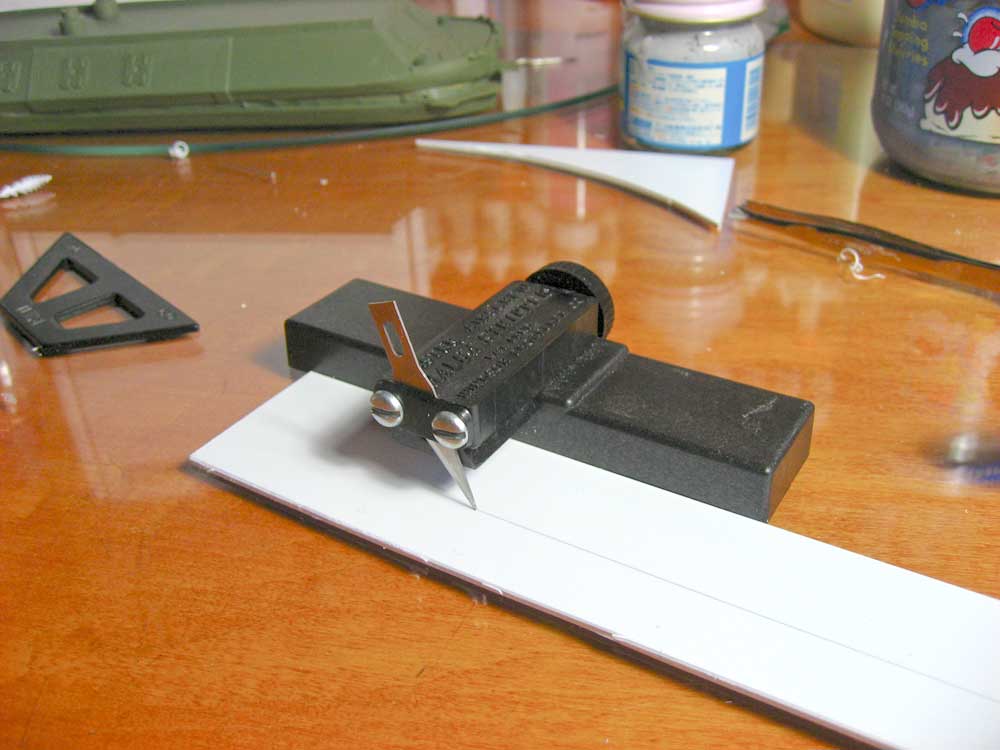

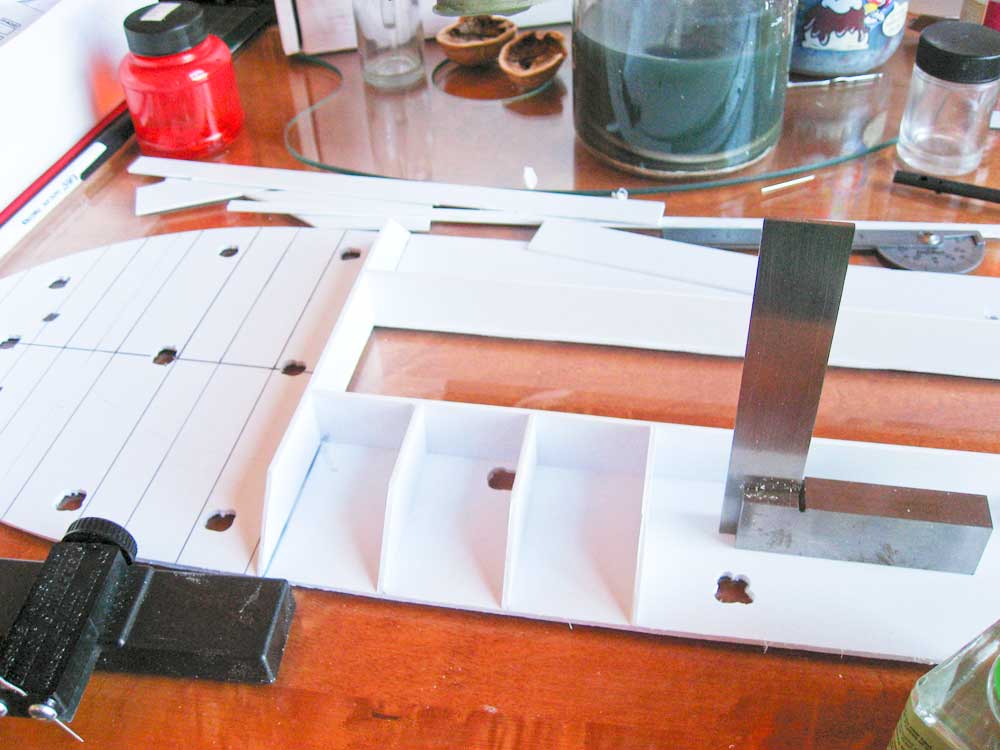

The City Class gunboats hull was completely parallel between the upper and lower levels. Measuring this distance and allowing for thickness of plastic, I came up with a frame height of 21mm. Fortunately, my strip wood/styrene cutter's maximum extension was exactly 21mm. Couldn't have planned it any better.

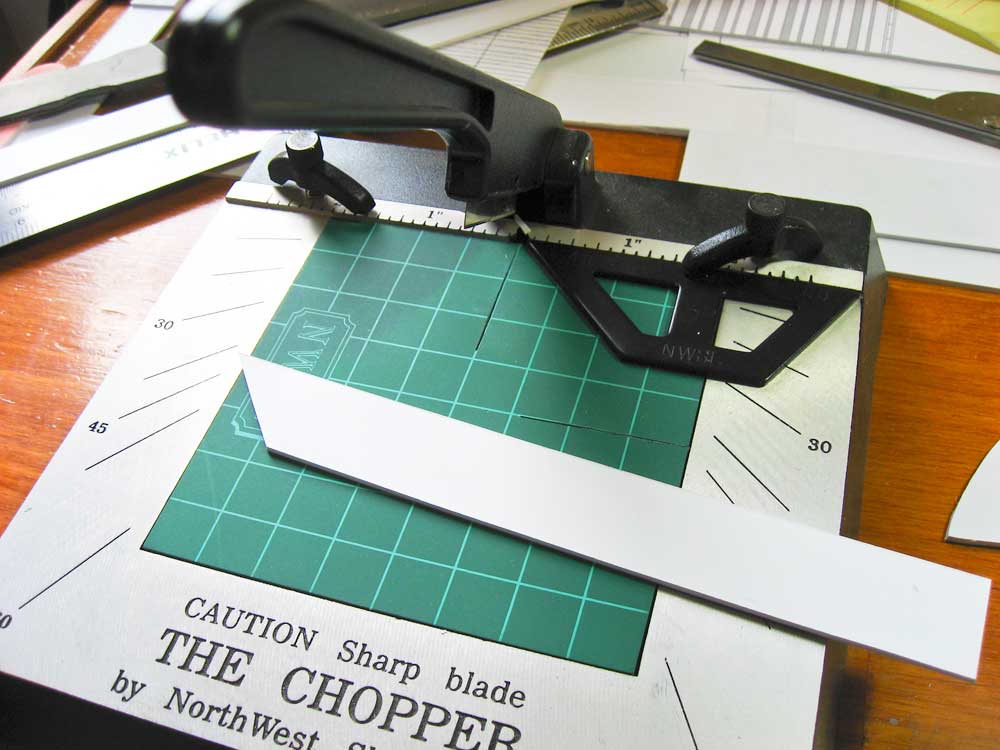

And continuing on the "that was easy!" track, MOST of the hull angles for the frames are 45-degrees. Out comes the chopper.

Everything cut to length and with the 45-degree angles cut, assembly was quick and straight-forward.

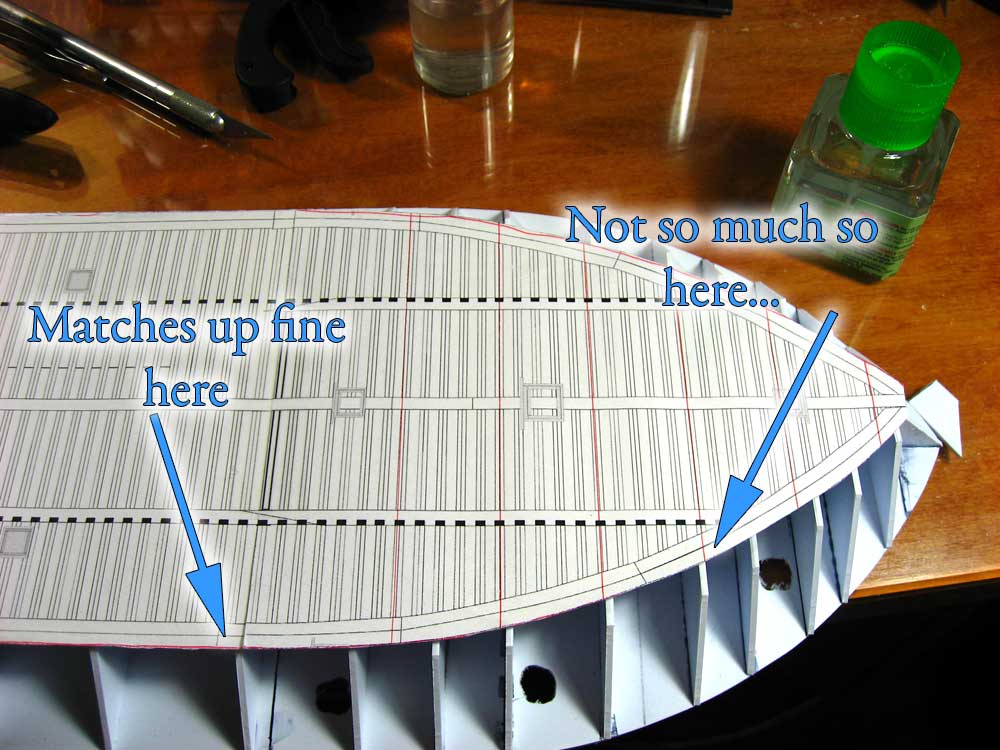

Until it came time add the lower part of the hull.

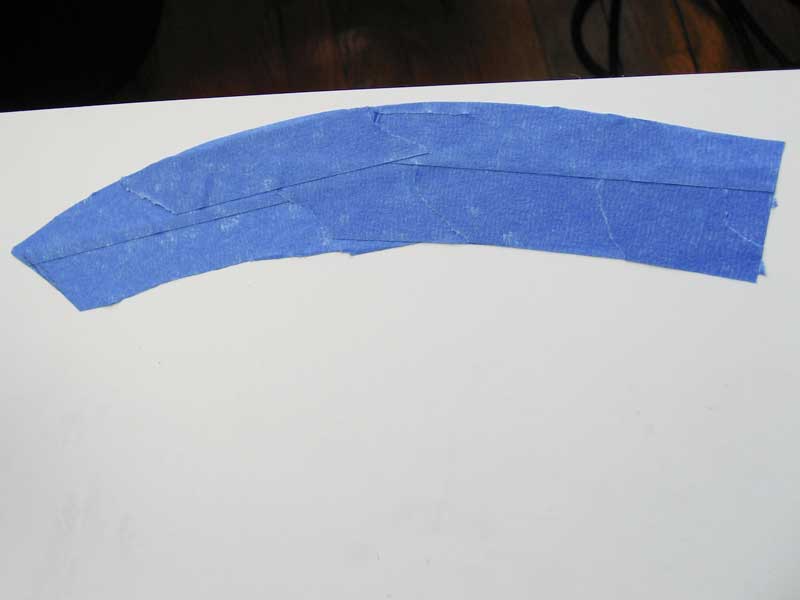

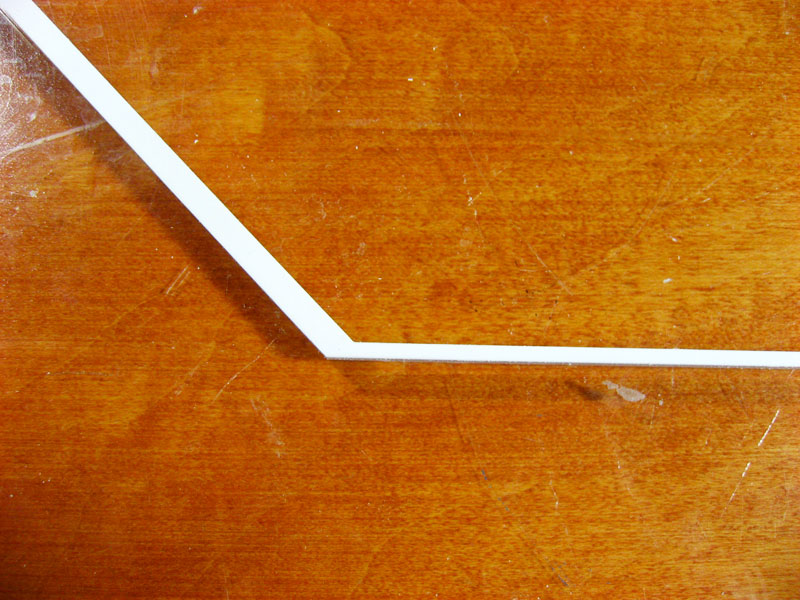

One of the sets of plans I had showed that EVERY angle on the hull was 45-degrees. As can be seen in the above image, that doesn't work out so well when you get to the forward and aft part of the hull. In retrospect I should have figured that out before hand, but oh well. I lost a few hours to marking the new frame angles, snapping off three of them aft and 8 of them forward, cutting them again, then attaching once more. Much better after all of that extra work: