Welcome to MSW’s Scuttlebutt! Here’s the news for the day.

Makin Island Continues on Road to Full Fleet Readiness

Source: US Navy

SAN DIEGO --- USS Makin Island (LHD 8 ) returned to port Feb. 24 following a weeklong underway that focused on Ship Self Defense System (SSDS) operational testing and evaluation.

With last fall's long-anticipated commissioning finished, Makin Island's crew has focused on preparations for Final Contractor Trials (FCT) later this year.

Although preparations began well before commissioning, Operations Officer Cmdr. Max DuPont said it is an ongoing process, and the command still has a way to go.

"After [FCTs], the ship is a true Fleet asset, and the Fleet can fully employ all the capabilities that LHD8 brings," said DuPont. "It's like buying a car. The warranty and break-in period is about to end on all the work [Northrop Grumman Shipbuilding, Gulf Coast] has done, so you want make sure it's right, and you want to run it through its full paces and have a mechanic make sure everything's right before you say, 'Yes, I'm ready take this car on a long cross-country trip.'"

The "mechanics" DuPont referred to are the evaluators from the Board of Inspection and Survey (INSURV), who evaluates new ships and existing ships for congress.

To help prepare for that, and to assess Makin Island's new SSDS system, Operational Test and Evaluation Force (OPTEVFOR) evaluators spent this past week testing weapons systems, such as the Close-In Weapons System (CIWS) and the NATO Sea Sparrow Missile Launcher, for functionality and tracking effectiveness. Earlier in the week Expeditionary Strike Group 3 personnel assisted in the crew's mock runs of common FCT evolutions such as equipment and procedure inspections and space walkthroughs.

ESG's efforts played an integral part in LHD8's preparations by helping to identify and validate concerns that that will be fixed in preparation for FCT.

Watchstanders were also tested for operator proficiency by OPTEVFOR. Using years of training, including that from Makin Island's tenure as a pre-commissioning unit, they demonstrated the weapons systems' abilities to challenge different types of targets.

"During SSDS testing, aircraft that would approach the ship were equipped with jamming pods and other tactical gear that flexed the ship's weapons systems," DuPont said. "These aircraft would run various profiles -- high altitude to low altitude, sea skimming, multiple aircraft -- in an effort to test our combat systems' responsiveness. A recommended engagement meant a system responded properly, which they each did."

Operations Department's Lt. Cmdr. Chad Simpson also pointed out that training has become much more scenario-based for the crew's benefit.

"We've actually remodeled [some of the scenarios] so that they're consistent, more realistic and are better for the operators overall," said Simpson.

In fact, Simpson said all of this at-sea period's training prepares the crew early for transition from an industrial environment, when the ship goes into its Post Shakedown Availability (PSA) this spring, to full-performance mode after FCTs. Once the crew proves they combat readiness, ship operability and self-training, they will be ready to move onto the next chapter in Makin Island's young history – deployment.

"Every time this awesome ship gets underway we gain more confidence in the systems and realize the truly advanced capabilities this unique ship brings to the fleet," said Executive Officer, Capt. Jim Landers. "The crew is ready to load up the blue-green team of the Navy and Marine Corps and get in the game!"

Cutting Edge: Construction Begins At Carriers’ Portsmouth Base

Source: UK Ministry of Defense

Work began today at Portsmouth on the first of two new aircraft carriers. As steel cutting commenced on a section of the hull, Portsmouth became the fifth UK shipyard to start construction on the program. The naval base will be the future home of both Queen Elizabeth Class carriers.

Defense Secretary Bob Ainsworth pushed the button to start the laser cutter. He said:

“Here in Portsmouth work is just beginning but across the country in Devon, Newcastle, Glasgow and Rosyth work is already under way. In all, six shipyards across the UK will be involved in the manufacture of the ships’ hulls, supporting up to 8,000 jobs in the construction and up to another 3,000 throughout the supply chain. The progress already being made to deliver these assets which will be a cornerstone of future defense policy is a testament to the skill and professionalism of UK industry.”

This is the first of three blocks that BAE Systems Surface Ships will build for the ships in Portsmouth. At 70m long and 40m wide, it will use 6,000 tonnes of steel. It will house space for machinery and supplies as well as switchboards and some accommodation.

BAE Systems’ role in the Carrier build program at Portsmouth is in the order of £800M, forming a substantial element of the workload at the Naval Base, where the company employs over 3,000 people, including around 200 apprentices.

First Sea Lord Admiral Sir Mark Stanhope said:

“The two ships of the Queen Elizabeth Class will be the largest and most powerful warships ever built for the UK, each equaling four acres from which to project airpower anywhere in the world. With eighty per cent of the world’s land mass within 500 miles of the ocean, the carriers will provide unparalleled access and flexibility. They are vital joint assets for the future of defense.”

Managing Director of BAE Systems Surface Ships Alan Johnston said:

“This is a very proud day for our workforce here in Portsmouth and comes on the back of our work on the Clyde, where another large part of the carrier’s hull is already taking shape.

“The design and build of ships of this magnitude is a massive engineering feat and a real testament to skills harnessed in our industry across the UK. We will continue to work closely with our partners in the Aircraft Carrier Alliance and to invest in the skills of our employees and our facilities not only to deliver the Royal Navy’s future flagships, but also to secure the long-term future of the UK’s warship building industry.”

Construction of the ships is progressing, and a national project that draws on the skills of shipyards throughout the UK is underway. This includes the shipyards at Glasgow, Rosyth, Newcastle, Devon and Birkenhead, as well as around a further 100 contracts throughout the supply chain. Some of the sections of the first ship’s flight deck, called sponsons, have already been delivered to Rosyth, where the ships will be assembled. In Spring, the first of the blocks of hull are also due to leave for the Scottish shipyard from Appledore in Devon. Many of the key components for the ships such as the diesel generators and the turbines have also already been manufactured.

BACKGROUND NOTES:

1 Six shipyards will together construct the nine blocks that make up the hull:

-- BAE Systems, Glasgow

-- Babcock, Appledore

-- Babcock, Rosyth

-- A&P, Newcastle

-- BAE Systems, Portsmouth

-- Cammell Laird, Birkenhead (due to begin Summer 2010)

2. The innovative Aircraft Carrier Alliance is a single integrated team in which MOD acts as both partner and client. Fformed from MOD, BAE Systems, Babcock and Thales UK, it is responsible for delivering the Queen Elizabeth Class ships on time and to cost.

HDW Tests New Battery Cells for Submarines On Board the Solar Catamaran “PlanetSolar”

Source: ThyssenKrupp Marine Systems

HAMBURG/KIEL, Germany --- Howaldtswerke-Deutsche Werft GmbH (HDW), a company of ThyssenKrupp Marine Systems, is testing innovative lithium ion battery cells on board the solar catamaran “PlanetSolar”.

The boat is financed by the German entrepreneur and solar pioneer Immo Ströher in close cooperation with Knierim Yachtbau GmbH, the shipyard that built the catamaran, and the battery manufacturer GAIA Akkumulatorenwerke GmbH.

HDW will now enter the final development phase for a new generation of energy storage systems that is designed for future use on non-nuclear submarines.

The Chairman of HDW’s Executive Board, Mr. Walter Freitag, states: “Lithium ion technology is an enormous step forward for submarine batteries. These cells were developed by GAIA, with the support of HDW and exclusively for us. In comparison to the lead acid batteries commonly used so far on board submarines, they feature much greater capacity and a longer life expectancy.

“In addition, they are virtually maintenance-free. Due to the very high demands in the submarine construction sector and in order to ensure operational safety on board, HDW has developed a comprehensive safety concept for system integration. The solar catamaran is the prototype for first operation of the lithium ion technology on board a manned vessel.”

HDW has an advisory role during integration of the currently largest lithium ion battery in the world on board “PlanetSolar” and is supporting Knierim with technical know-how. This particularly applies to the safety aspects of operating lithium ion technology on board.

Thanks to the successful cooperation with Knierim and GAIA in this project, HDW has been able to further extend its position as world-wide leaders in the field of submarine propulsion technology, a position that was established with the development of air-independent propulsion on the basis of the fuel cell plant.

The Marine Systems business area is a leading European systems house supplying submarines, naval surface ships and premium segment yachts to customers globally. The company’s outstanding shipbuilding competence includes repairs, services and ships’ components. Roughly 7,500 employees in Germany, Greece and Sweden are committed to meeting the broadest possible range of challenges.

CBS interview with Lieutenant Commander John D. Bulkeley

Today’s website is the transcript of the CBS interview with Lieutenant Commander John D. Bulkeley as he tells of his PT Boat squadron’s actions during the Normandy invasion. Enjoy.

This Day in U.S. Naval History

1935 - The Naval Security Group is born when OP-20G becomes the Communications Security Group.

1941 - President Franklin D. Roosevelt signs the Lend-Lease Act.

1942 - In a Motor Patrol (PT) boat, Lt. Cmdr. John Bulkeley leaves the Philippines to take Gen. Douglas MacArthur to Australia.

1945 - The first Navy landing craft crosses the Rhine River at Bad Neuenahr.

1965 - Market Time patrols begin off the South Vietnam coast.

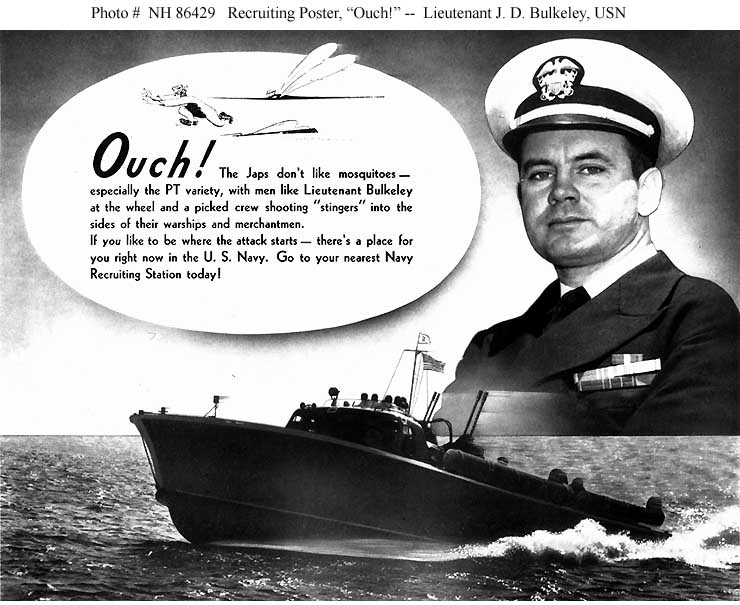

Photo of the Day

Recruiting Poster featuring Motor Torpedo Boat (PT) commander Lieutenant John D. Bulkeley.

Gator