These are slow builds, lots of learning, lots of tested new techniques and they just take while. Anyway I'm getting to the point where I can't avoid rigging any more.

So, I'm looking for any technique help I can get. Is there a product or technique that helps keep the rigging tight. I'm toying with the idea of wax or maybe a bit of white glue and water.

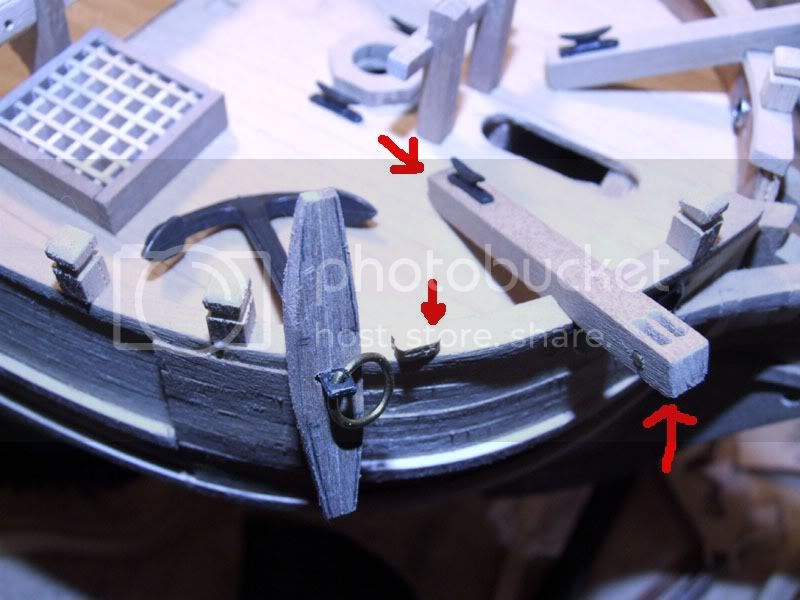

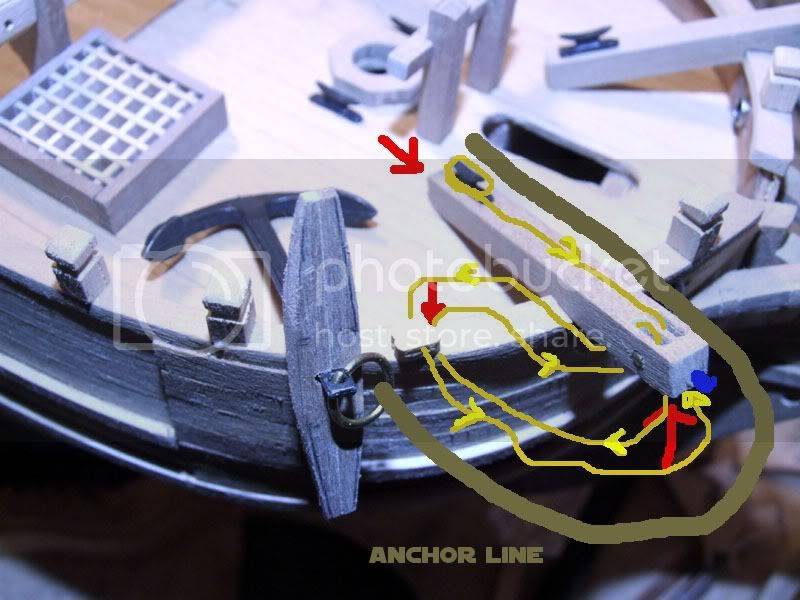

How about research? I'm starting with the anchors (seemed simple enough). The instructions are horrible and you get one wide shot and no guide. I get that one end is wrapped around the cleat, but where is the other end connected- cleat end (drill a hole insert glue), or at the overboard end, or in the block?