I don't own a lathe or a mill, and I wanted a steam winch for a chain achor rode. All I could find was This brass electric winch with two drums but no gypseys (chain gears). I filed off the peens holding the drums on the shaft, pressed them off, inserted brass washers to simulate the gypseys, and pressed them back on. This copper chain was all I could find that was to scale. It should be studded to be authentic, so this is a compromise. If anyone asks me why an electric winch on a 1902 vessel, my response will be

"mind your own business"

.

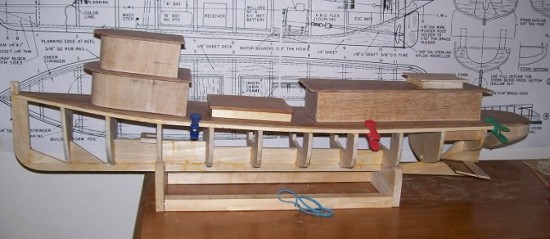

Here's the first photo of the superstructure on the planked hull. You can make out the purse boat davits on the stern, the anchor winch in the bow, and some added detail on the forward deckhouse and wheelhouse.

The railing is .025" piano wire which I annealed with a butane torch to make it bendable. The stanchions are from Cornwall. The ladder was fashioned here and its handrails are 3/64" brass rod. The navlights, searchlight, hooter, and radar antenna are also from Cornwall. The galley stack is a piece of 1/4" brass tube with a short length of 5/16" swaged onto the end of it. The hangar for the bell is out of scale; it will be changed.

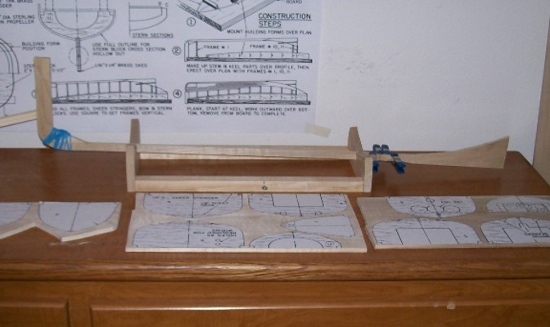

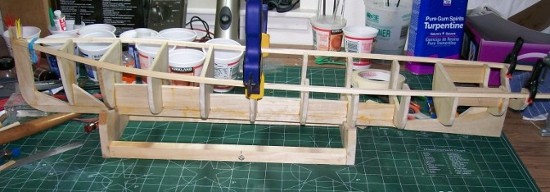

The rub rail installed. The stern piece is cut from 1/4" poplar, the stringers are 1/4 square spruce, hence the difference in color. Also visible is the 5/32" brass tube for the 1/8" rudder post.

The original anchors on the Helen (and most of the rest of the fleet) were danforth type, stowed on the deck and run outboard with a small davit on the bow. I had no room for all that gear plus the winch and wheelhouse companionway, so I went with navy type stockless anchors stowed outboard into hawsepipe fairleads, In this photo just dry fitted. Some of the fleet actually had this exact arrangement. The anchors are from Model Expo.

Here's the bow light, a white 3mm LED in a brass housing set below the crow's nest. I cut a groove from the light down to accomodate the wiring and backfilled it with the same filler I used on the hull.

Here's the rudder servo and speed controller installed. The link to the rudder post is dry fitted. Also, a good view of the planking from inboard, coated with polyester resin for waterproofing.

The phenolic washer under the link is to prevent tinning the rudder post and tube together when soldering the link on. The washer has to fit snugly on the post.

I'm using a 75 turn brush motor. I don't think I'll need a brushless because I'll be using 2.4ghz radio so I don't believe brush noise will be a problem. Time will tell.

First coat of paint on the hull. It's just to help me see where I need more filler & sanding. Also, the mast is stepped. Still to go: hang the boats, install the bulwarks and caprail, add the bitts, mooring bollard, stern rail, ratlines, boom, and rope rigging. Getting there!

Had to back up one. The plans made no provision for access to the rudder linkage. Too risky for me, so I added another removeable hatch.