Ahoy!

OK, so I mixed up the paint. Charged the air tank. Hooked up the airbrush hose. On the tellie

The Blacklist went to commercial and I scooted out the door with the airbrush, paint, thinner, and prepped model components.

It was 20°F but I quickly mixed the paint with the thinner (kept warm in my hoodie pocket) and started spraying. First a very thin coat to seal the edge of the tape. Move everything back in as the commercials end. Let dry. Next commercial and let loose the dogs of modeling! It was challenging in the cold; I had to keep bumping up the psi as the paint - more like a wash - cooled. Yet five or six coats later...

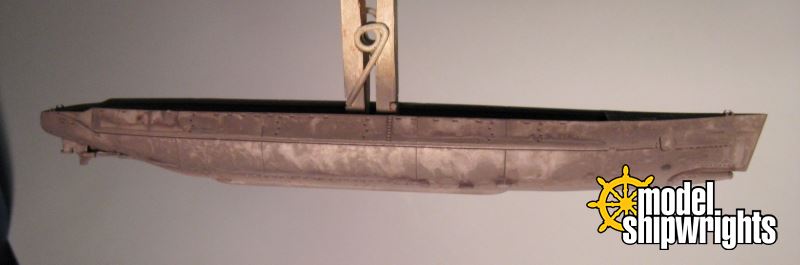

I have mixed feelings on my technique. I planned for the gray splotchy underpaint to slightly discolor the anti-fouling red, thus I did not prime below the waterline and used many thin coats. Overall I think it looks satisfying.

The tape removed it is time to start rusting the ol' shark up. I mixed up my very thin wash for 'spatter brushing':

...followed by using various rusty colors straight from the bottles and pots. I kept them thick to stipple and grind them into the hull, even streaking a bit here and there:

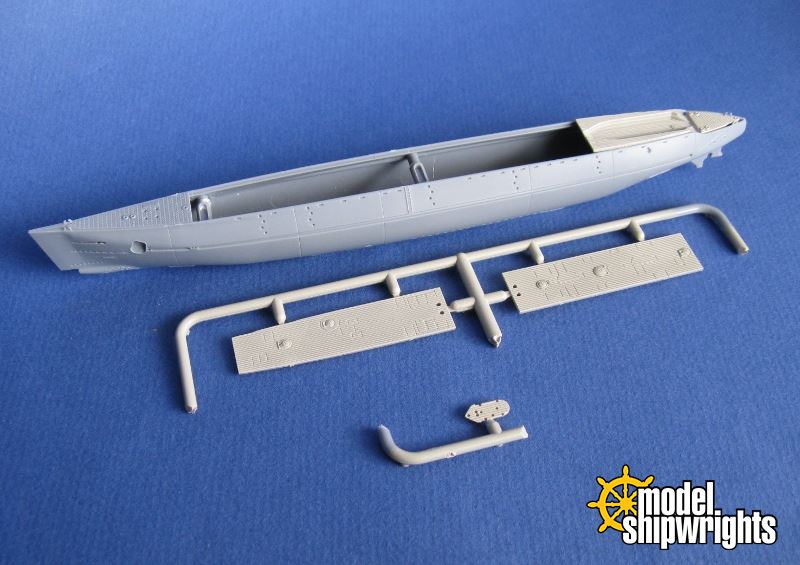

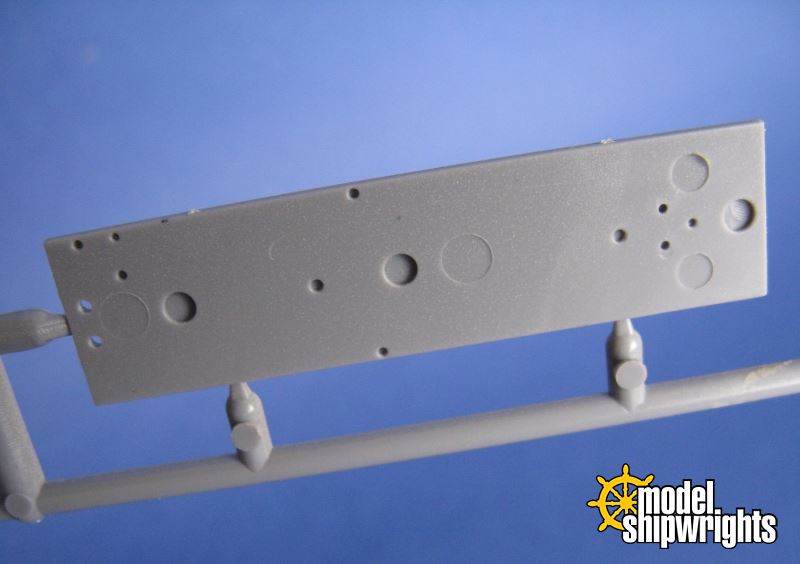

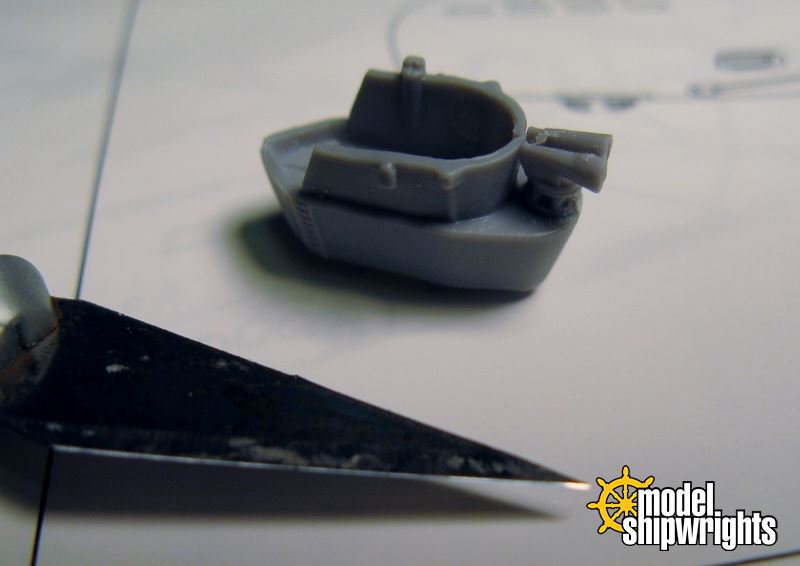

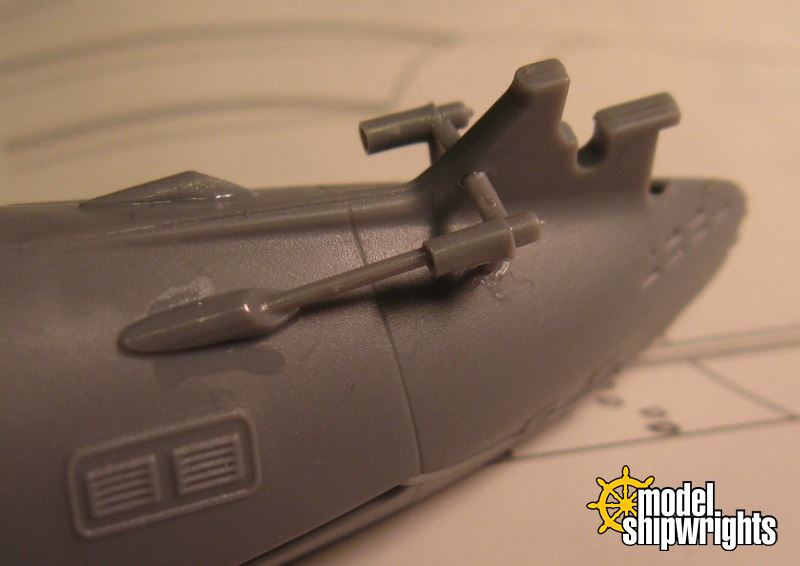

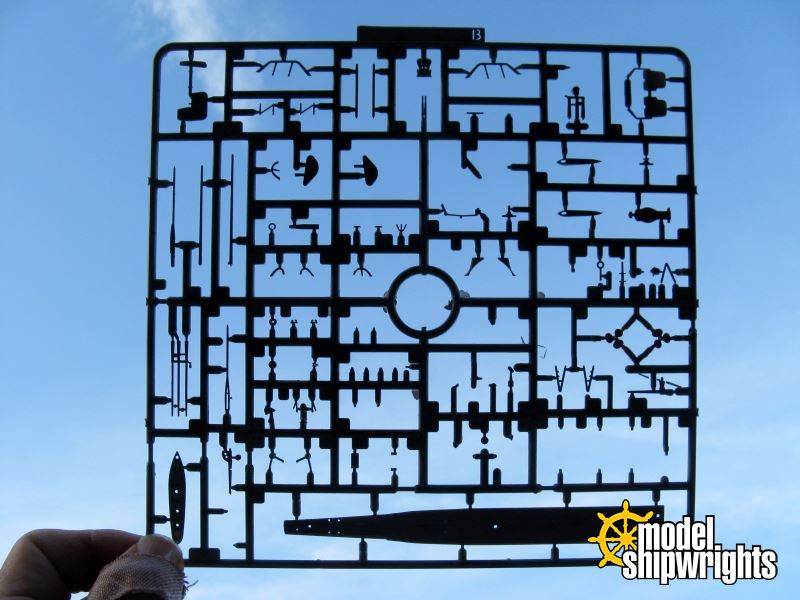

While it dried and the paint cured, I assembled the conning tower. This little rascal is small, but not as small as several of the periscopes and other equipment mounted on the weather deck. Inside the con are the only visible ejector circles I found. Perhaps the (kelp?) forest of plastic will obscure them?

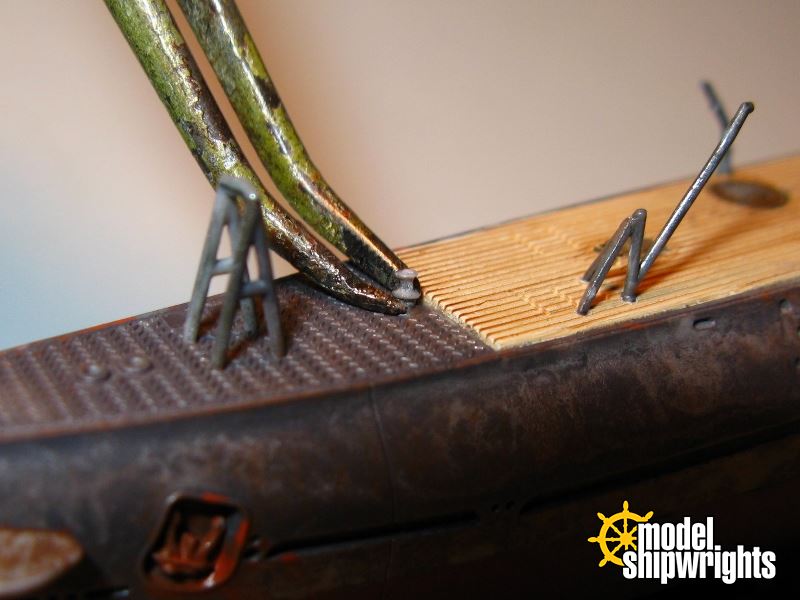

The diagonal apparatus held on the pedestal at the rear of the con deck is the passive radar.

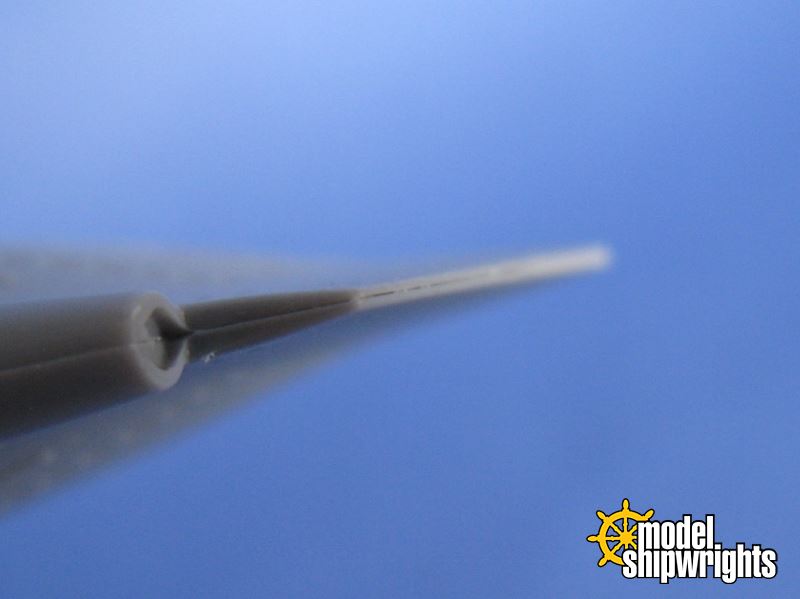

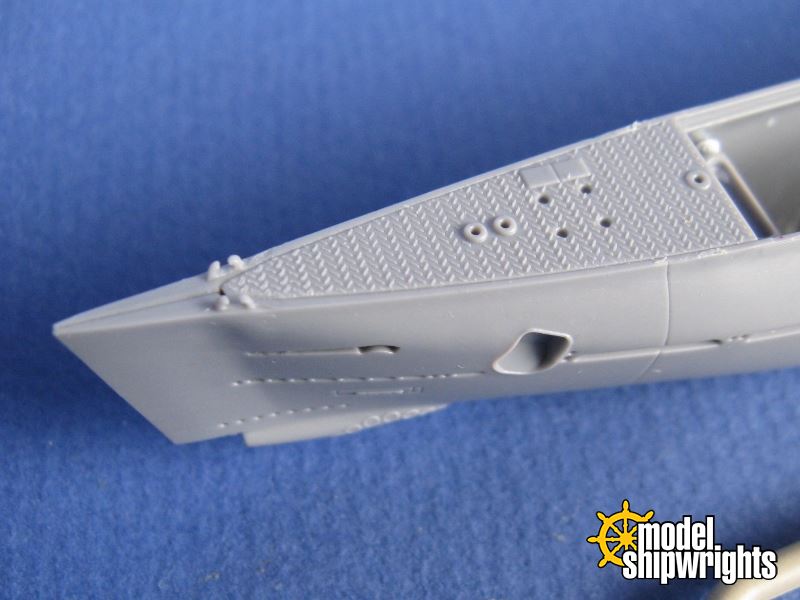

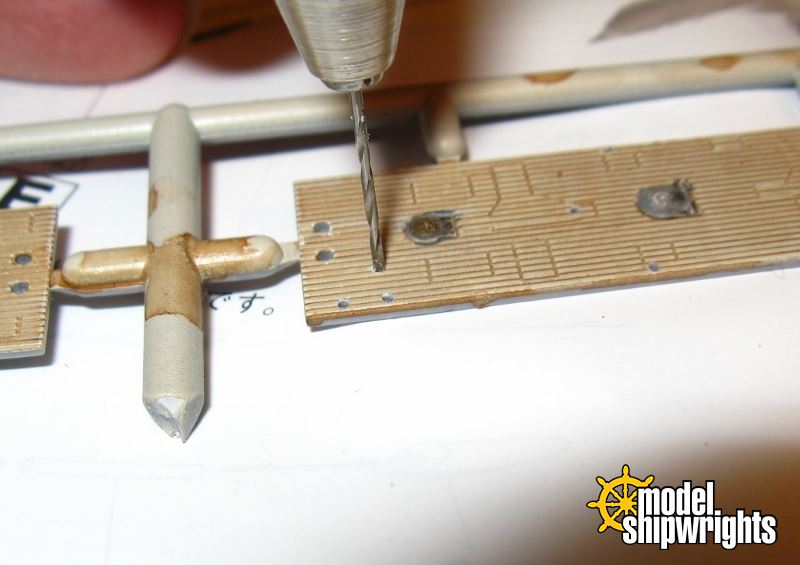

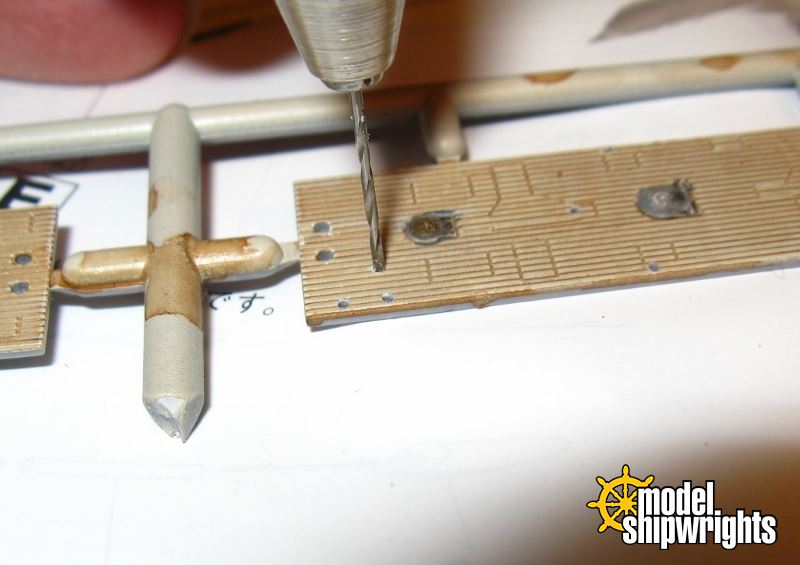

While those dried, I (hesitantly - I really like my clean bright decks) stained the decks with a mixture of umber artist ink mixed with diluted Vallejo Matt Finish. I also drilled out the many .4mm holes required to insert the .4mm masts and fittings.

The wash also helped obfuscate the slight paint slops I made yet could not clean up when I painted the deck hatches. The aft deck is not (yet) stained. Ain't that pretty - see why I didn't want to do it?

(Think I could get way with saying the crew loves to holystone the deck around the

daihatsu?)

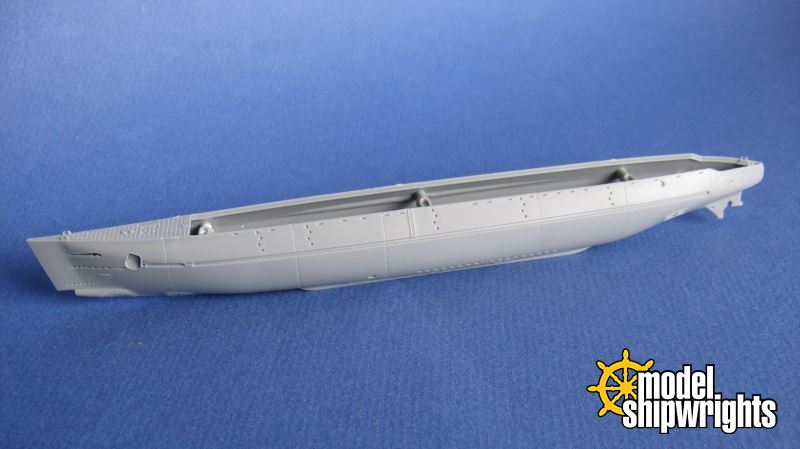

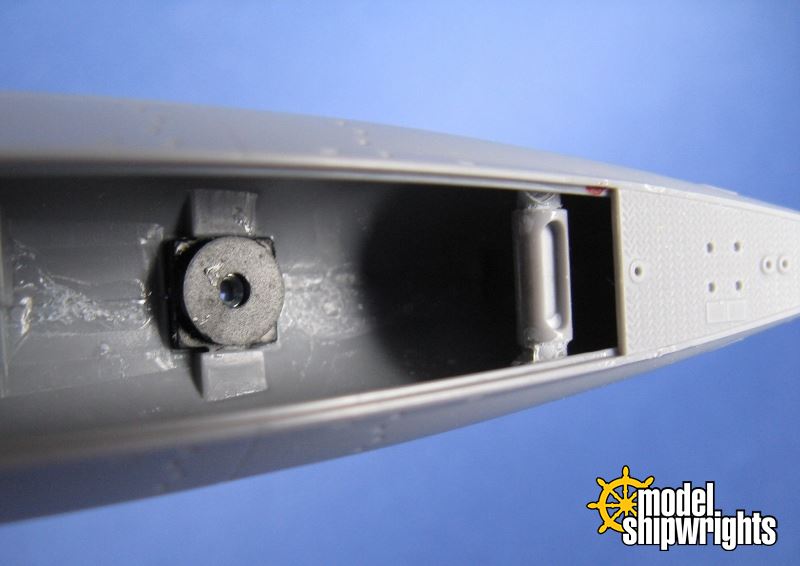

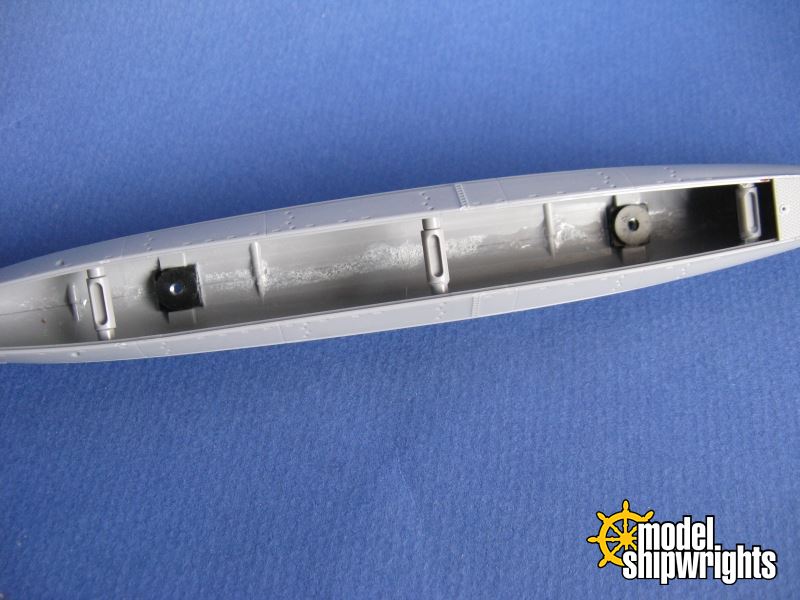

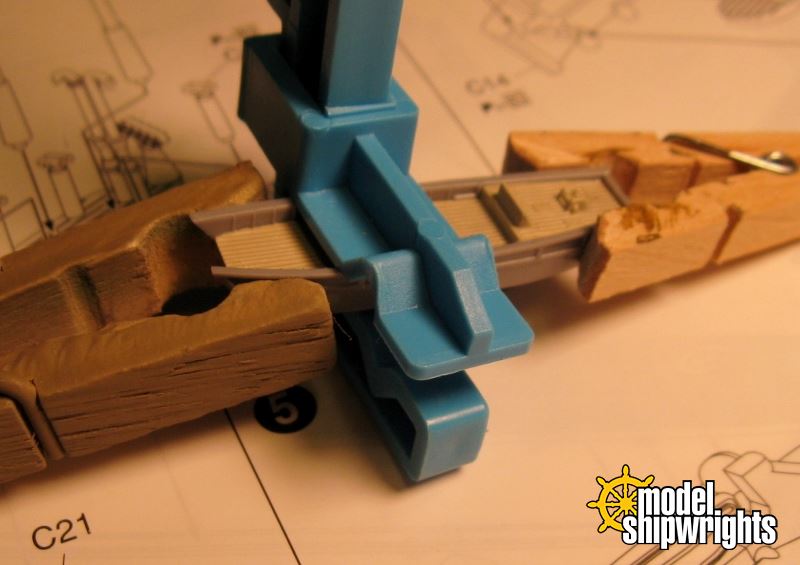

In the meantime I decided to assemble the stand. CA does not bind that plastic well for some reason. Fortunately the screws mated to the nuts inside the hull and held everything tight. I did this because it will make mitigate my fingerprints and clumsiness when working with the model.

I set the decks in to test-fit. I even added the incomplete conning tower. It will be about a week until I can return to I-365, until then I leave you with this view to whet your appetite!