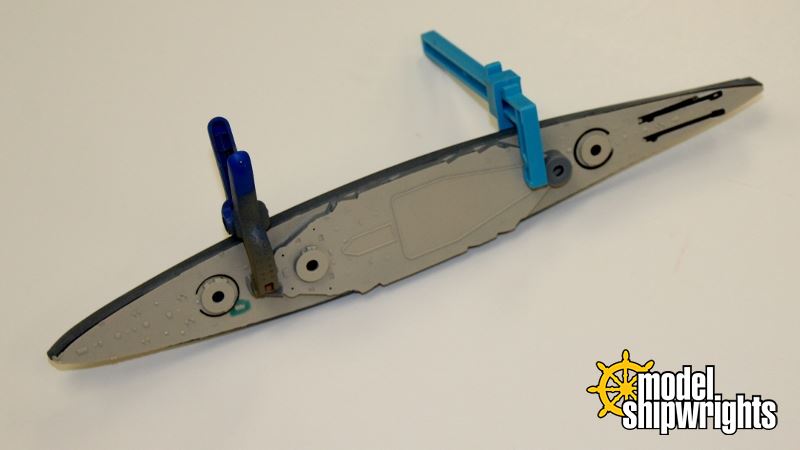

Yes, Derfflinger and I still exist! Not much to show for the past 11 months but here's an update.

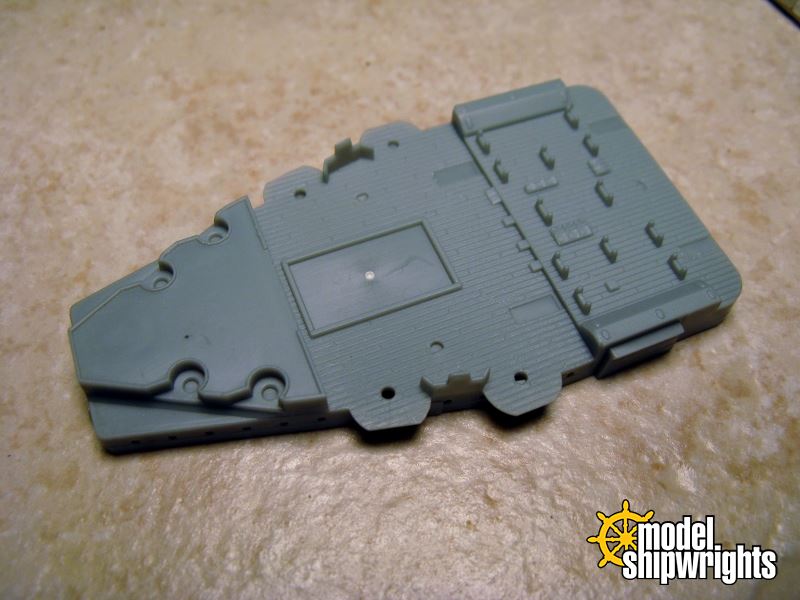

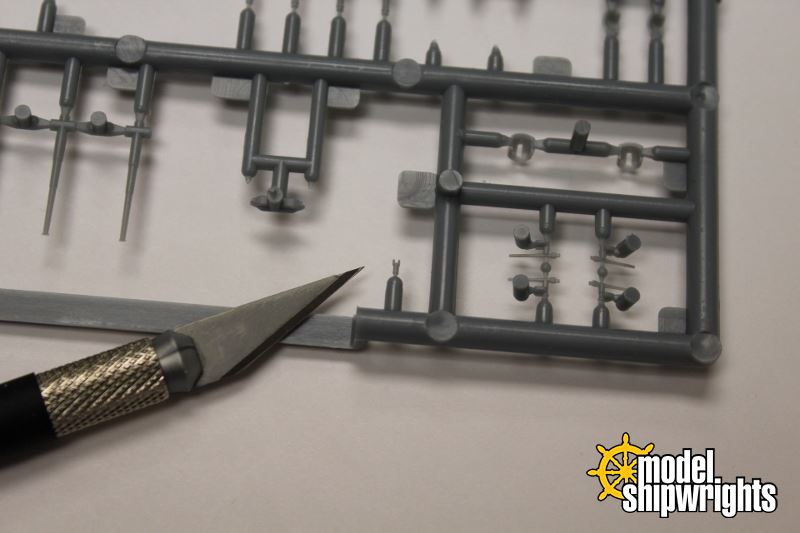

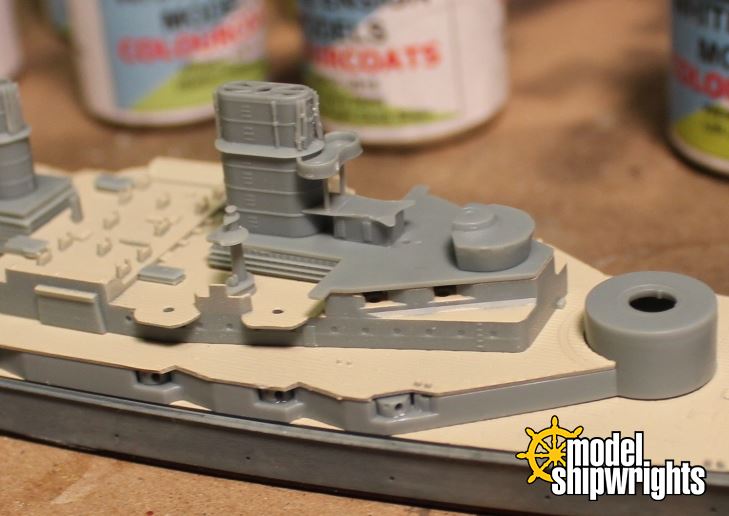

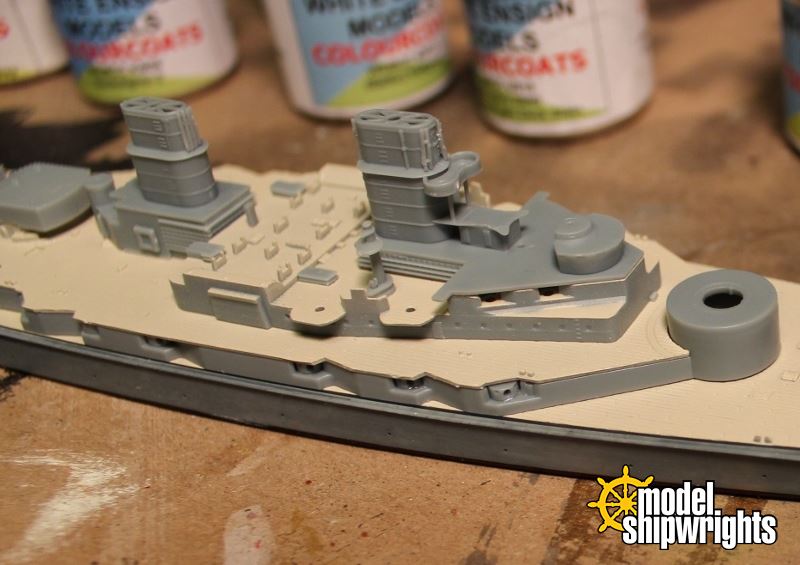

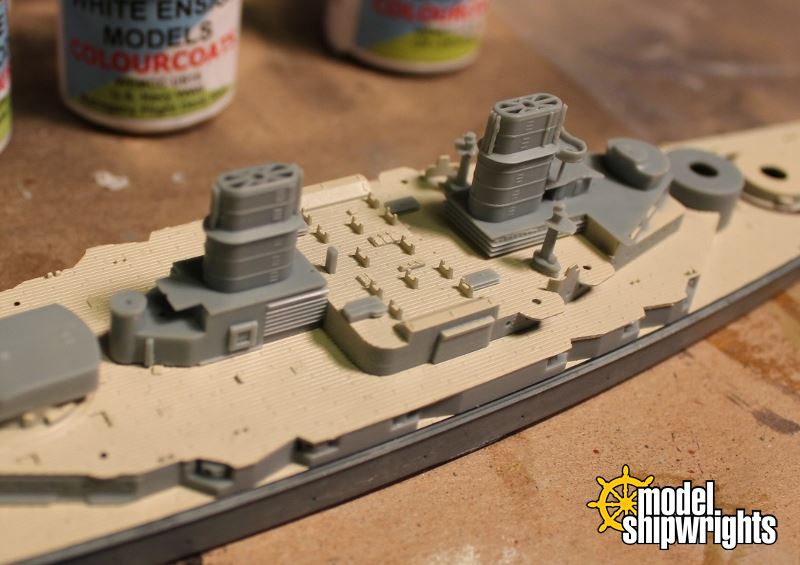

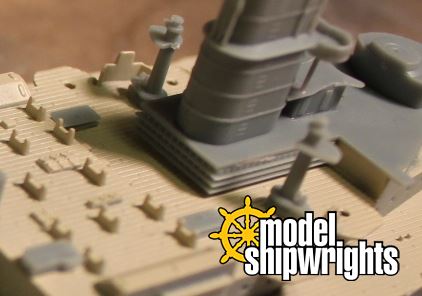

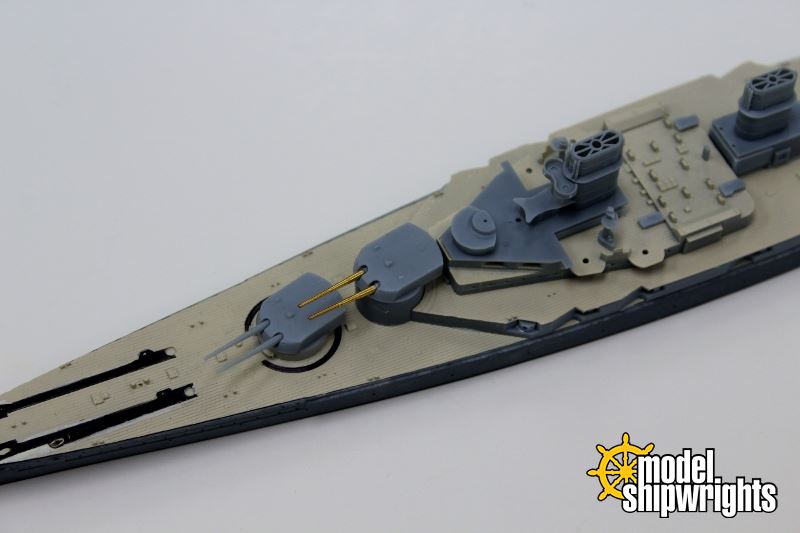

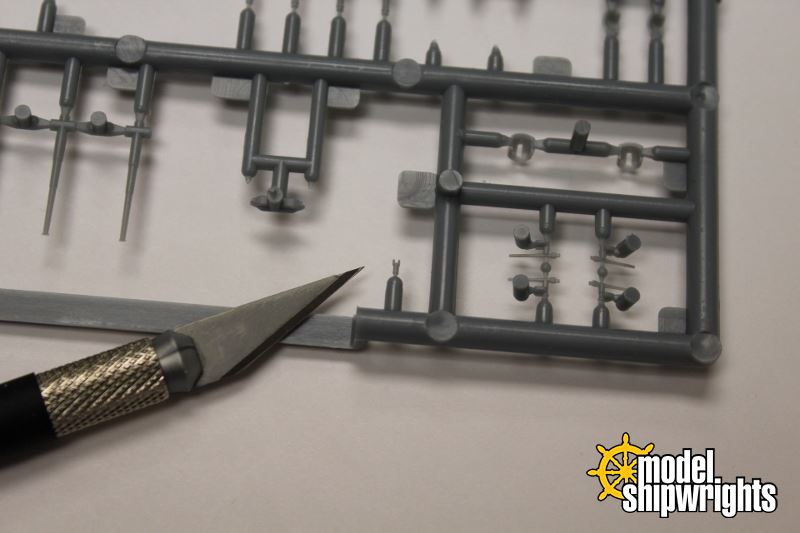

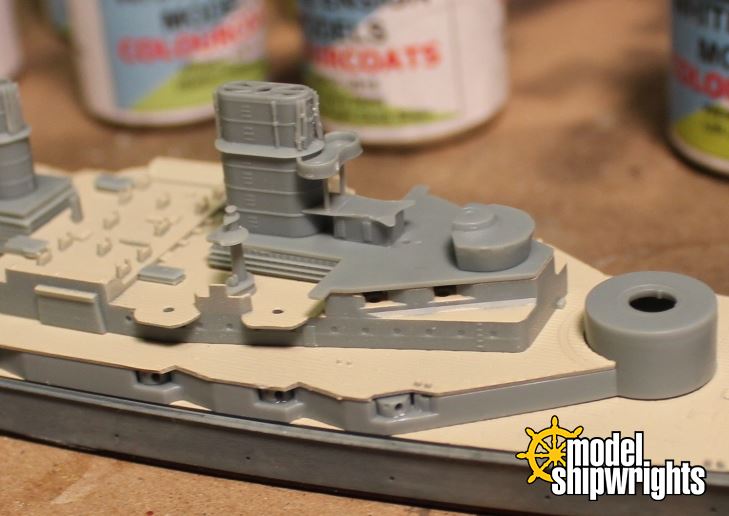

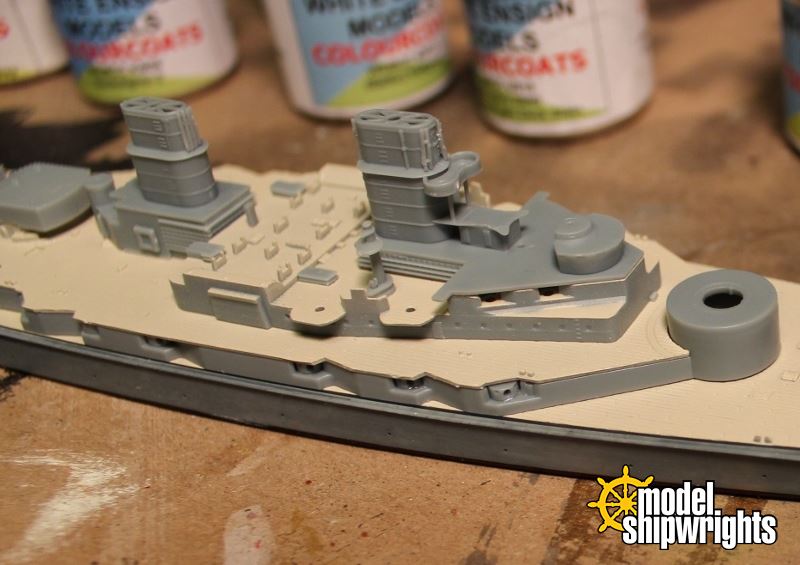

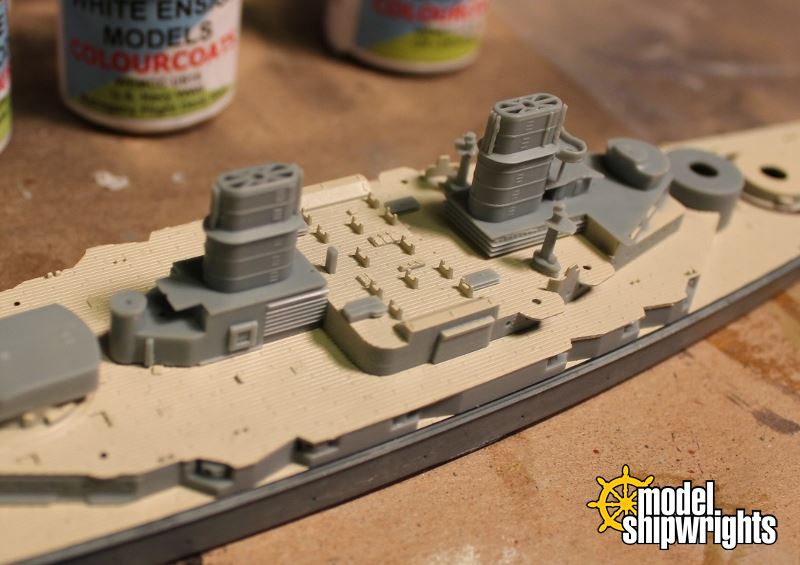

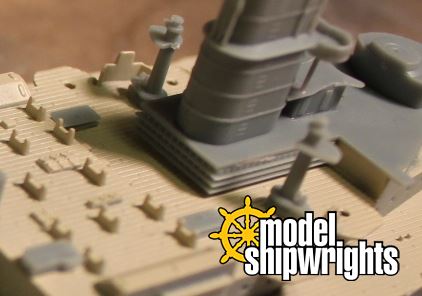

Assembly of Derfflinger is straightforward and smartly engineered. Decks and superstructures mate with remarkable precision. Yet the very small pieces require very pointy tweezers and the touch of a watchsmith.

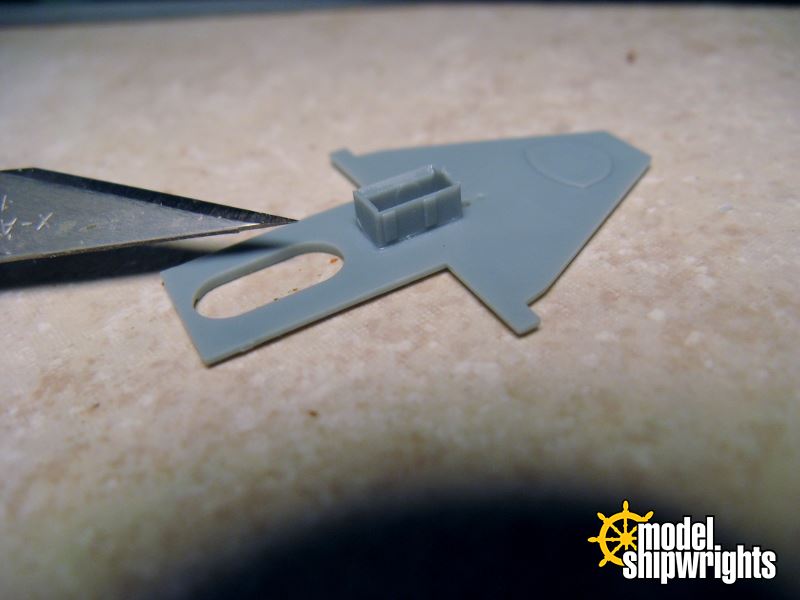

I had to use my stiletto-tipped tweezers by Wilder to hold some of them. For instance, the casement guns are two-piece assemblies: casements and barrels. The casements are held to the sprue by what seems to be robust connectors, yet as my sprue nipper clipped them, some parts would fly away. These tiny parts are prime candidates to loose in the carpet. However, the parts fit easily into the deck and hull.

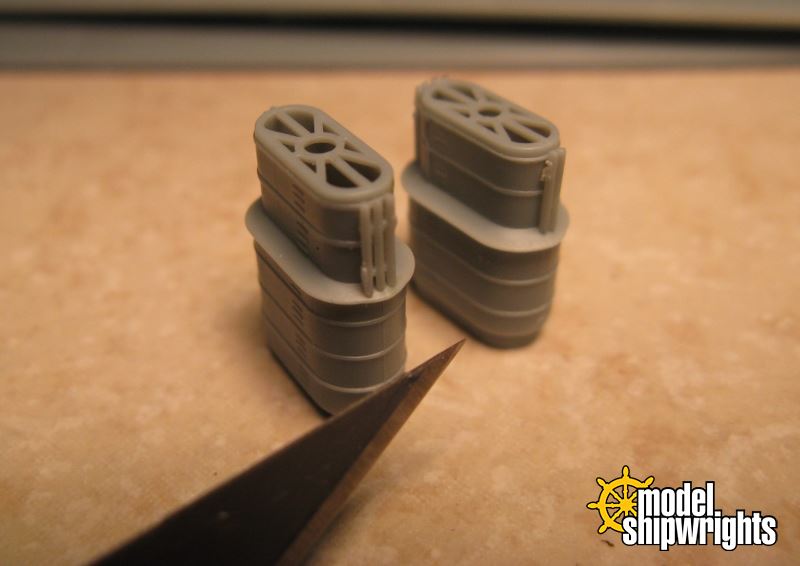

Flyhawk’s instruction sheet is beautifully printed with clean and clear illustration. However, they mislabeled parts B37, upper casement guns, as part B31. Part B31 and B32 are structures (louvered vents?) on the boat deck. Part H1 is also illustrated with a raised or depressed area for the stack to attach to, but the piece was not molded with that feature.

Both stacks have signal/searchlight platforms on the fore and aft sides. Several very well molded searchlights are provided for these. They are properly labled with the correct part number (B33) yet they are not shown in the instructions until near the end of the assembly sequence, and they are illustrated from the top. The graphics look more like a box. Fortunately, Flyhawk color-coded these and a bit of study makes it clear where these are to be mounted.

I plan to complete this model with little more paint than what you see now. However, I will use a few of White Ensign Models' Colourcoats, generously provided by a US distributor MidTenn Hobbies, located in Nashville, Tennessee.

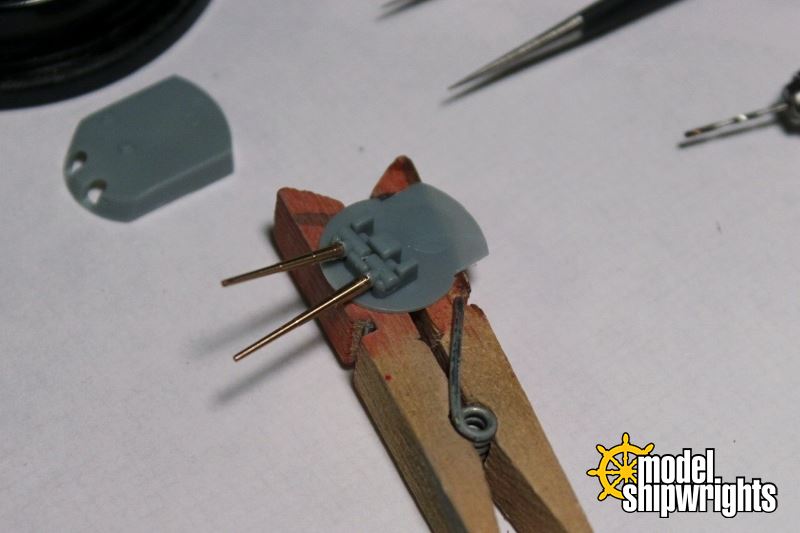

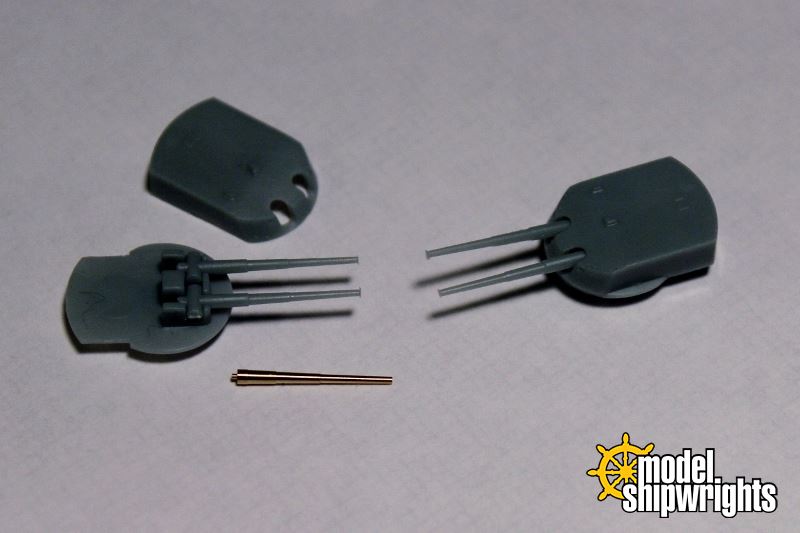

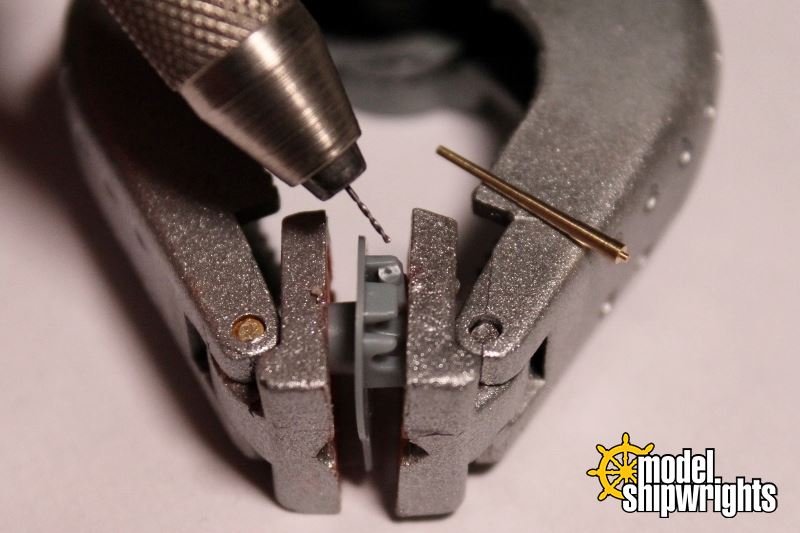

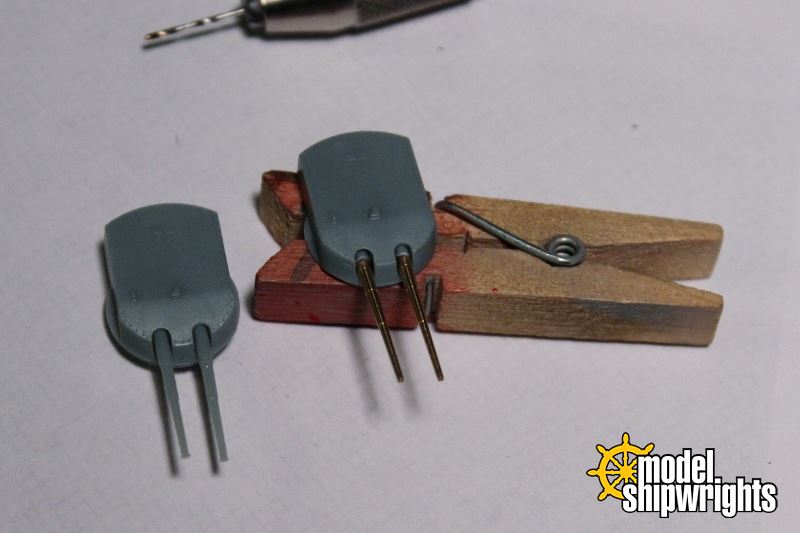

The hull halves have been joined to the bottom, the weight installed, and most is complete except for fiddly parts and P/E. However, the brass gun barrels will be used. While Flyhawk was great in making these, they are not easy to use. I will have to cut away the barrels where they mount into the turret, drill a miniscule hole, and attach the brass into the holes.

My Optivisor is getting a workout!

Check back soon!