A bit of a progress update as we go along.

I had to decide on a change of scenery: My job took me on one of the frequent trips to mainland China. I am now sitting in Zhuji, Zhejiang province some 300km west of Shanghai.

I am scheduled to be here until 29th, but it may turn out longer. Zhuji is mostly an industrial city with some nice corners, but I had seen them all on previous trips, so I am spending my time in my hotel. What better chance to build a model?

I am not certain, when I will have a chance to post these pictures, so I will take the chance to post whenever the omnipresent governmental censorship let me enter Modelshipswrights during the next days. Out here in the provinces I have a better chance than in the big cities like Shanghai to where I will proceed in a couple of days, as censorship isn’t as tight here.

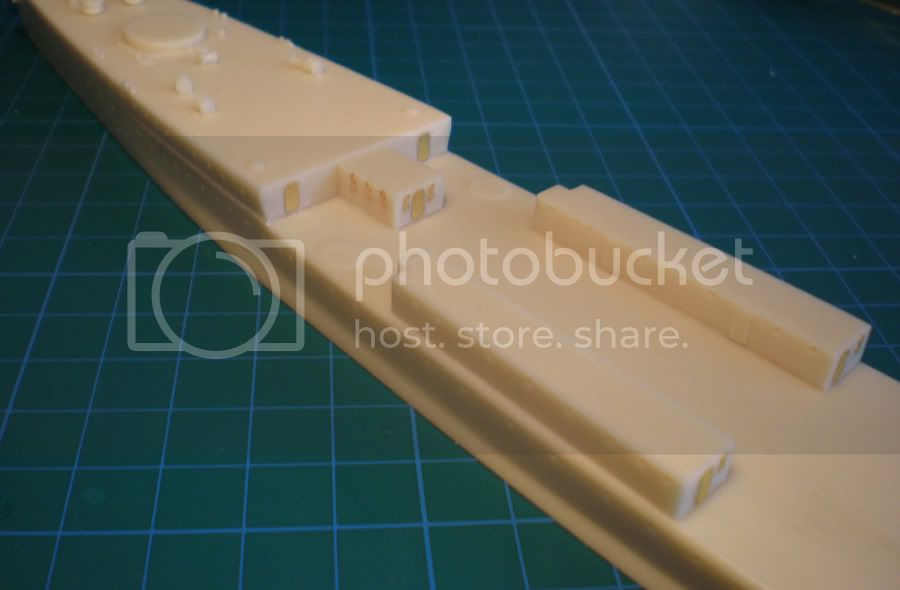

I have set up my workbench on my hotel room desk as best as I could and I should be able to do some damage. I took the essential tools set and references with me. Of cause some styrene sheets and rod and the better part of the PE collection are travelling with me.

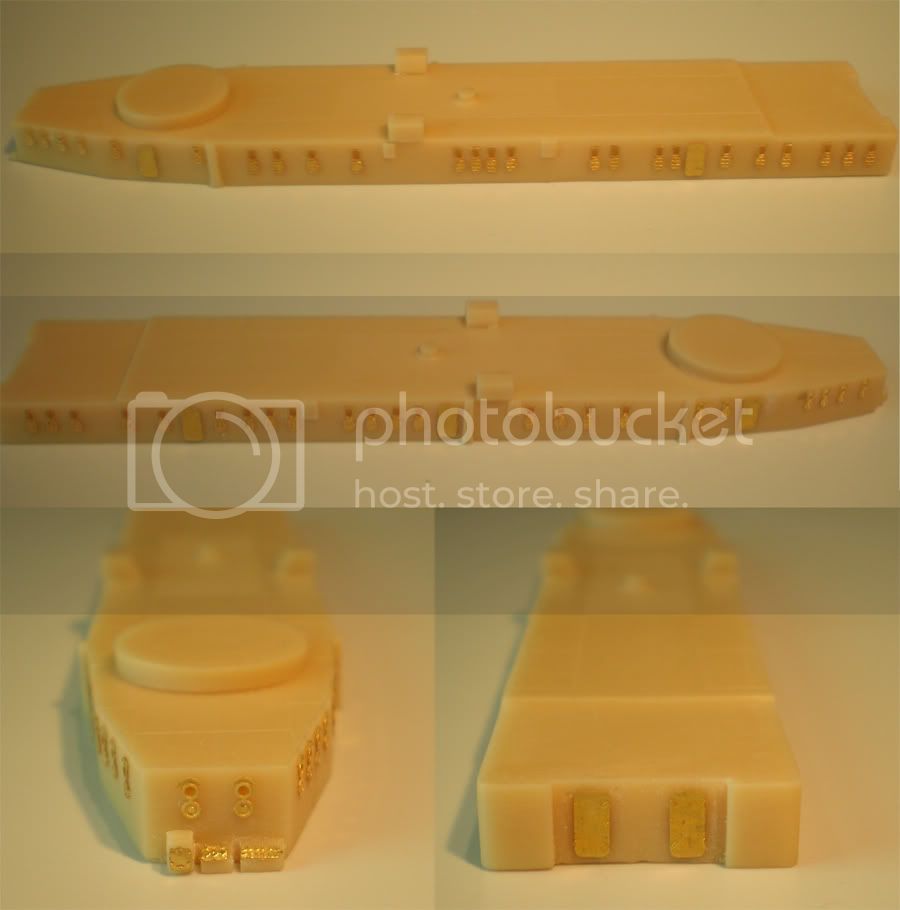

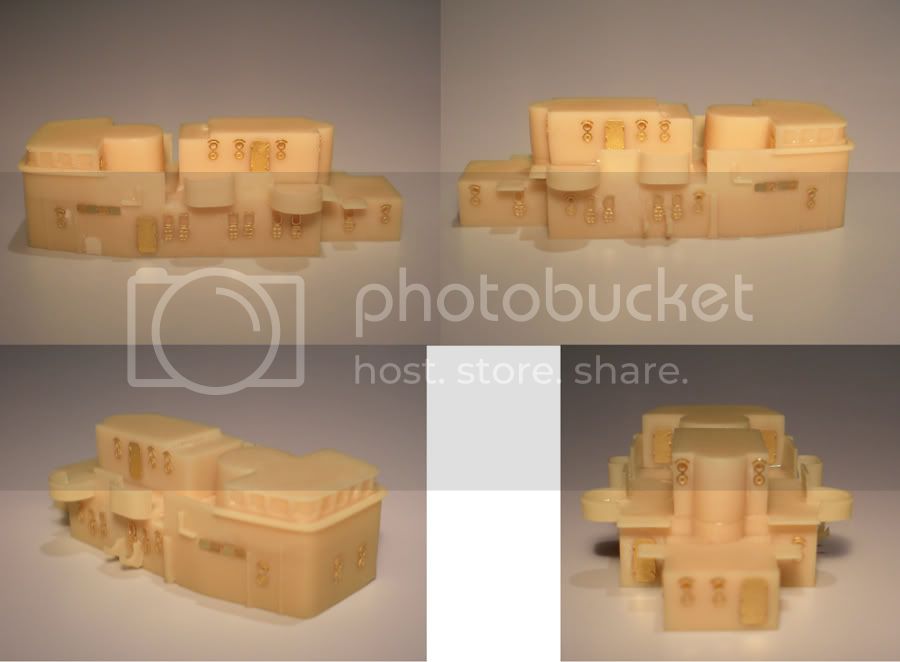

I have cleaned up all the parts except those too fragile to survive without the waver (see top of the picture). These parts will most likely be replaced by styrene or brass rod later. Next to the over pour I have now removed about 90% of the cast surface detail such as porthole covers, doors, vents and reels as they will all be replaced by PE.

Now I got some 6-7 hours of modelling time before me. Lets see what I can do…