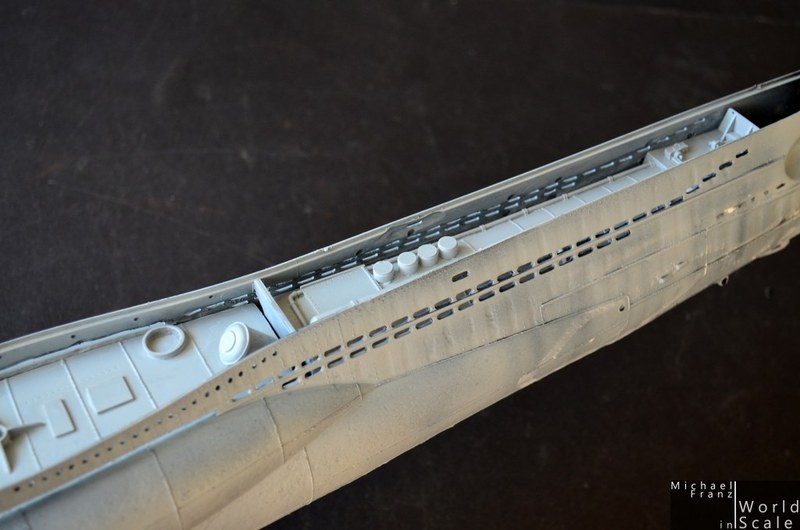

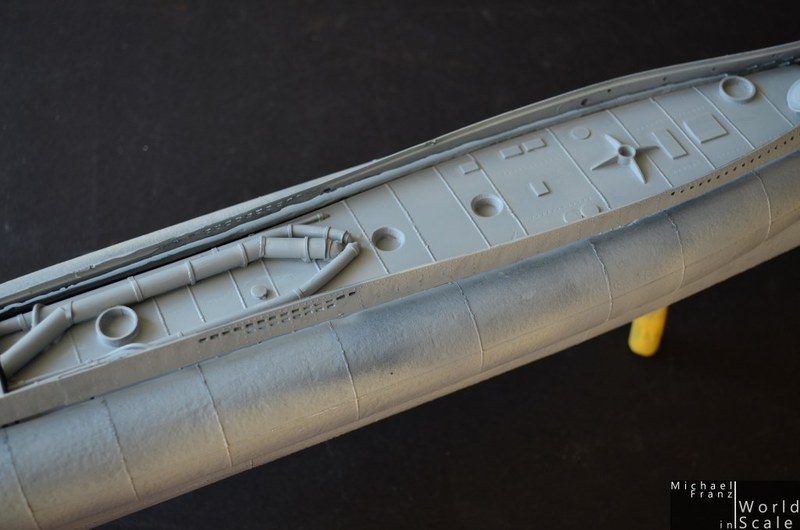

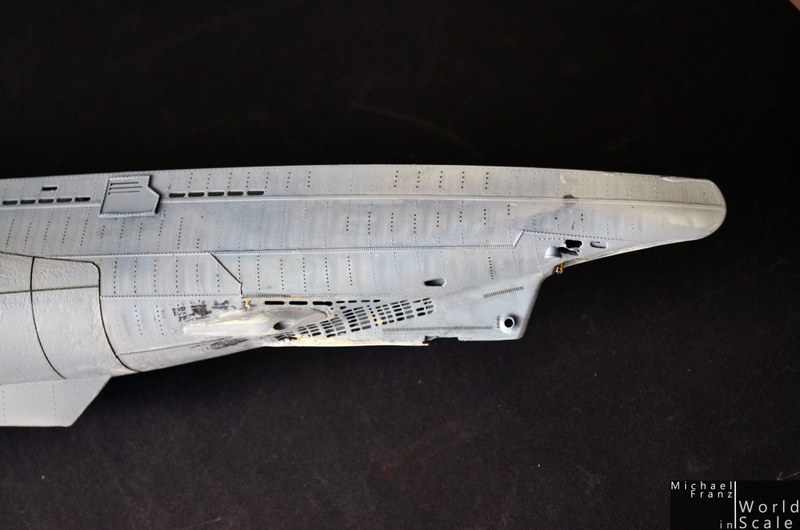

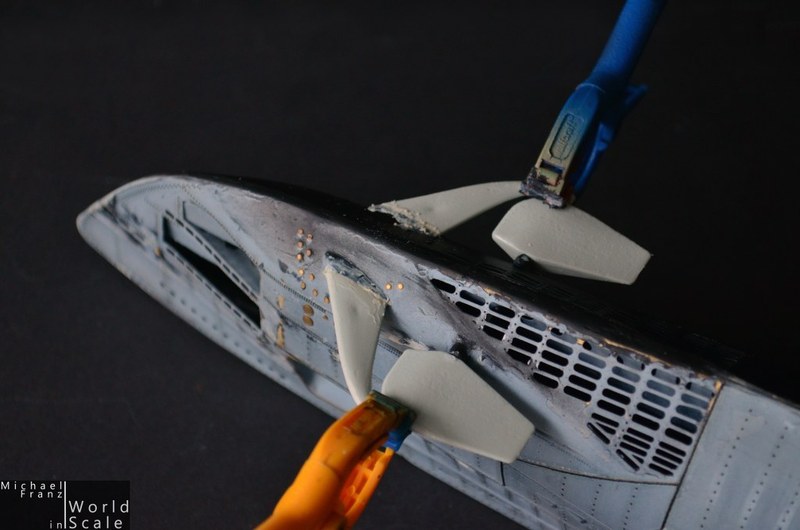

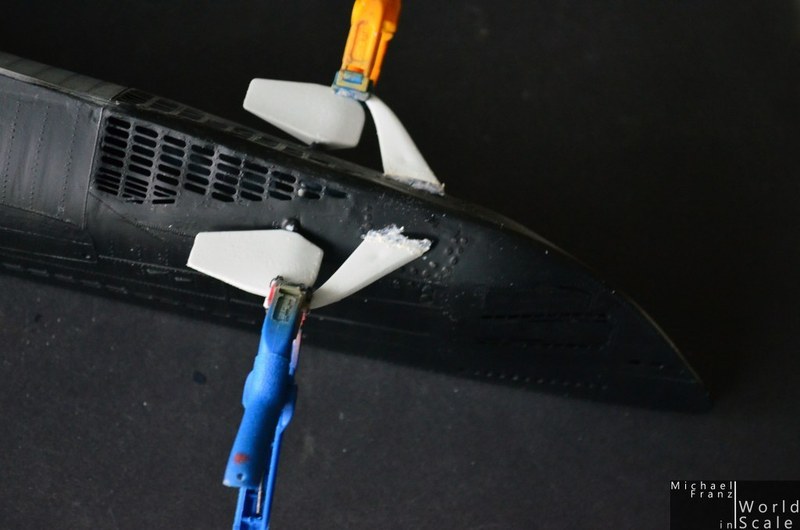

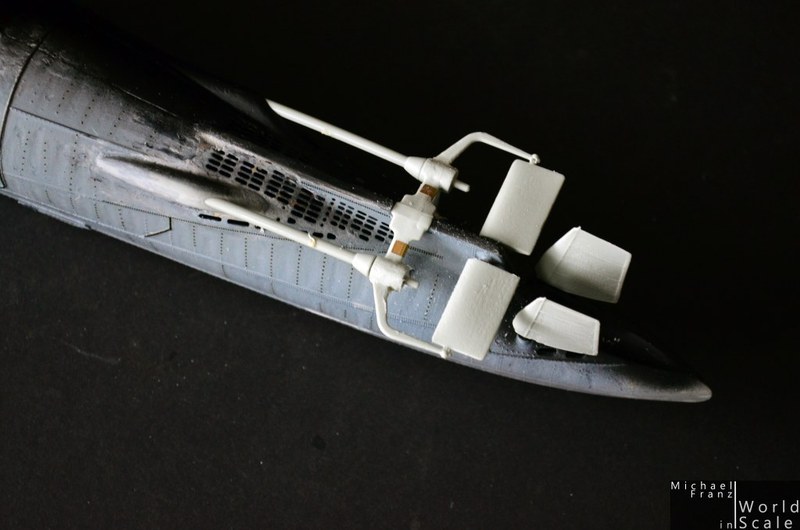

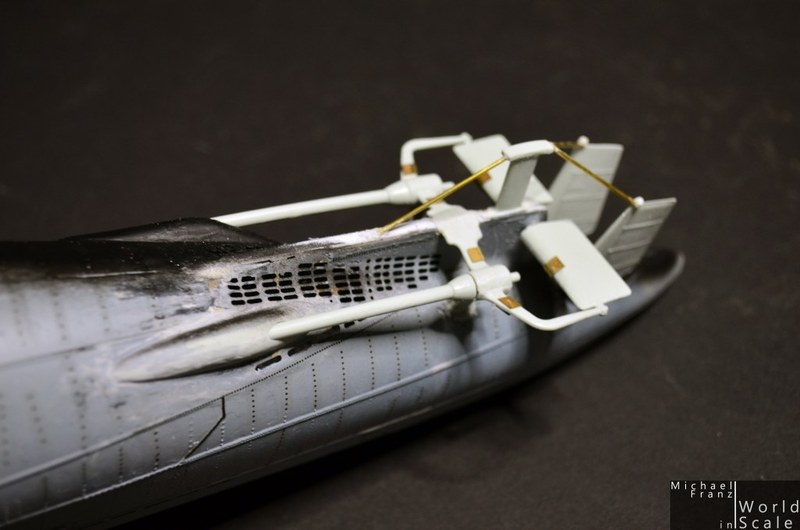

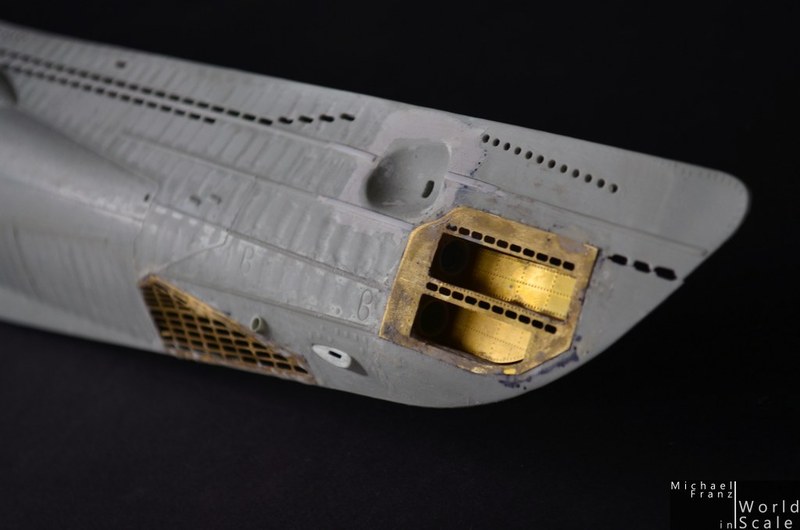

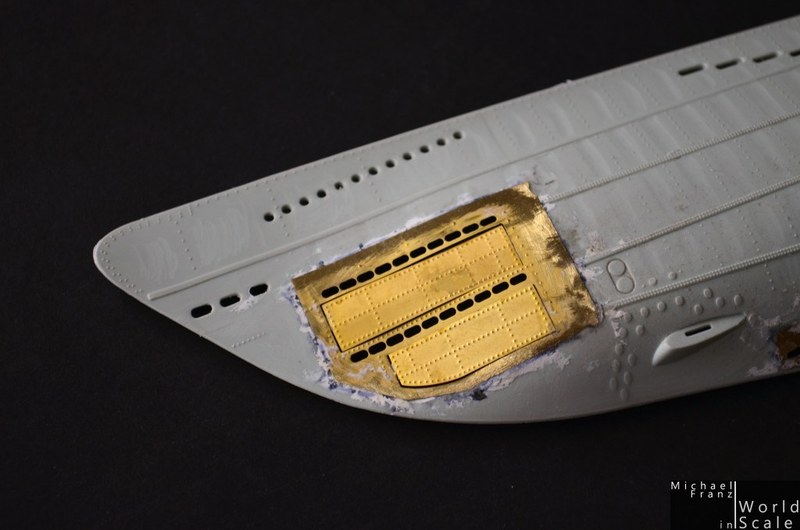

The boat received open torpedo doors on one side, closed ones on the other side. These are made of PE-parts, bend and glued in position. The open ones will receive further details later (PE-Parts). The closed ones were mounted with plastic stripes from the inside.

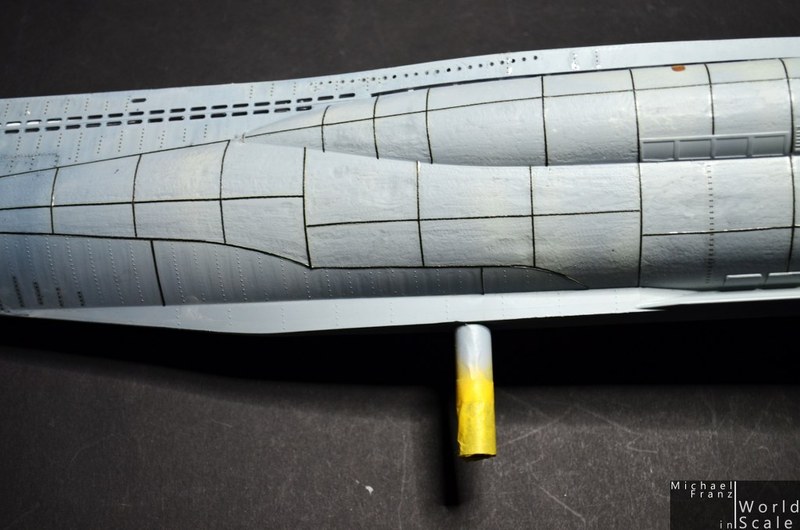

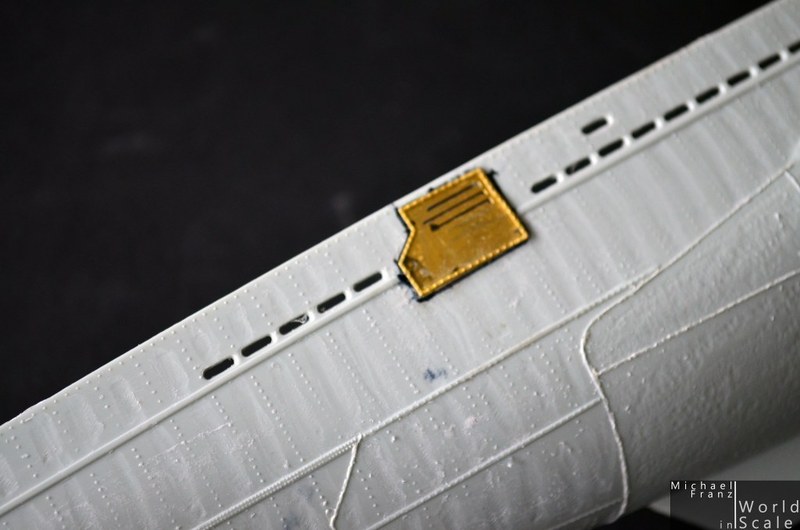

The exhaust is made of PE-parts with new openings on both sides...

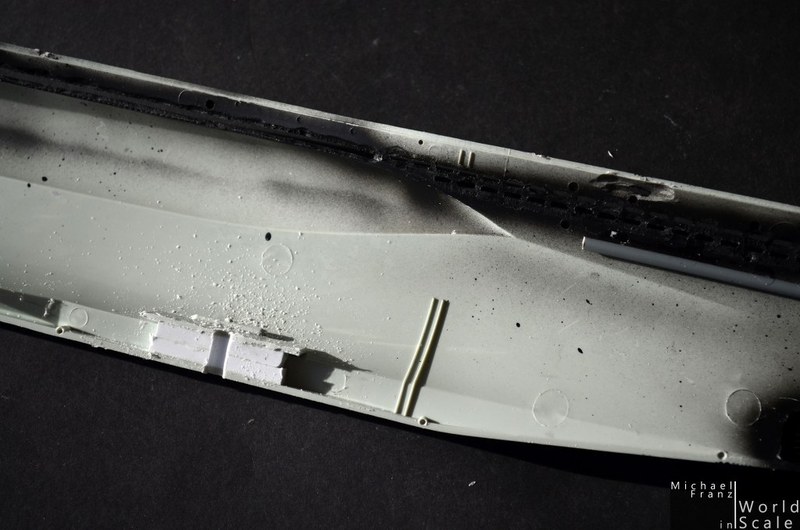

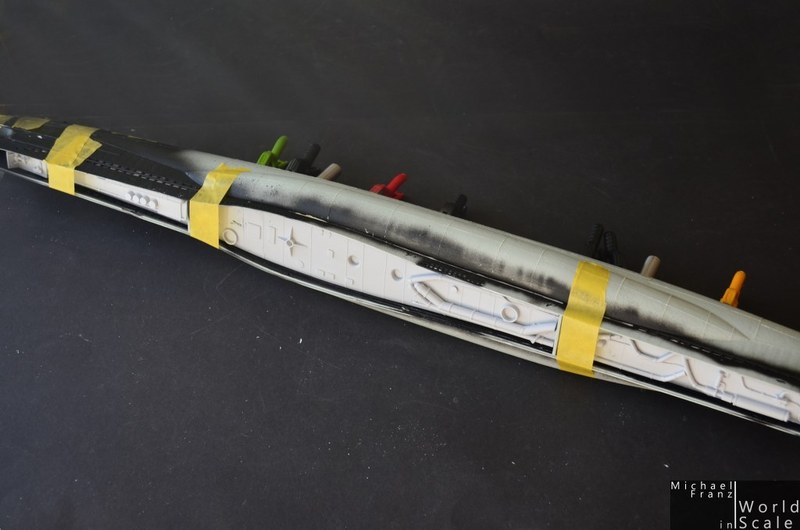

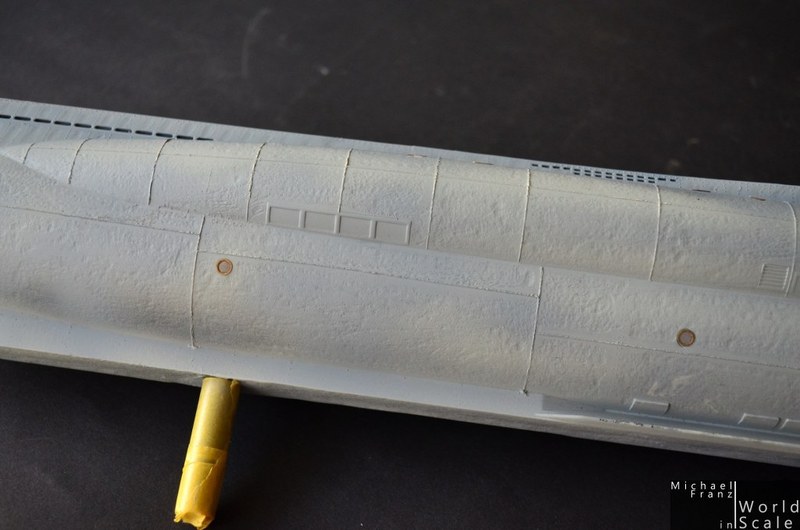

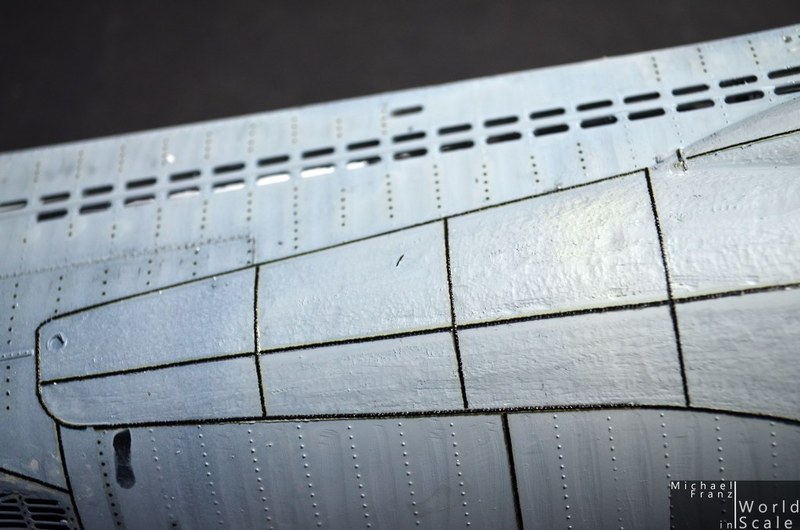

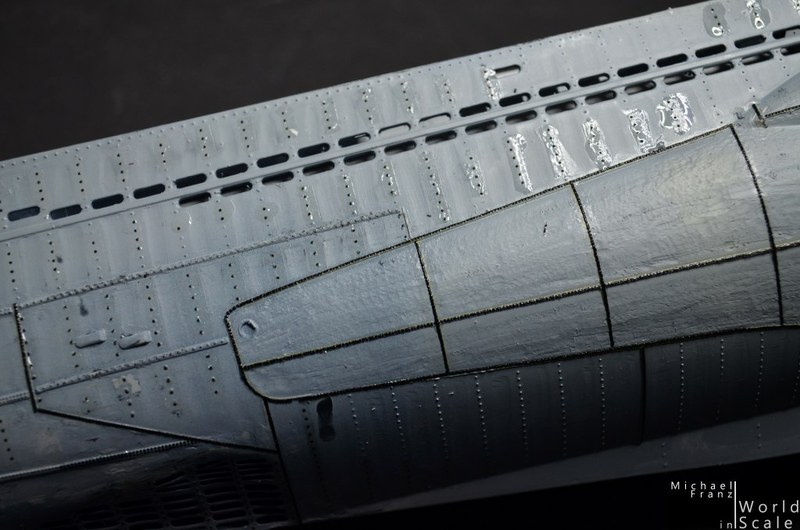

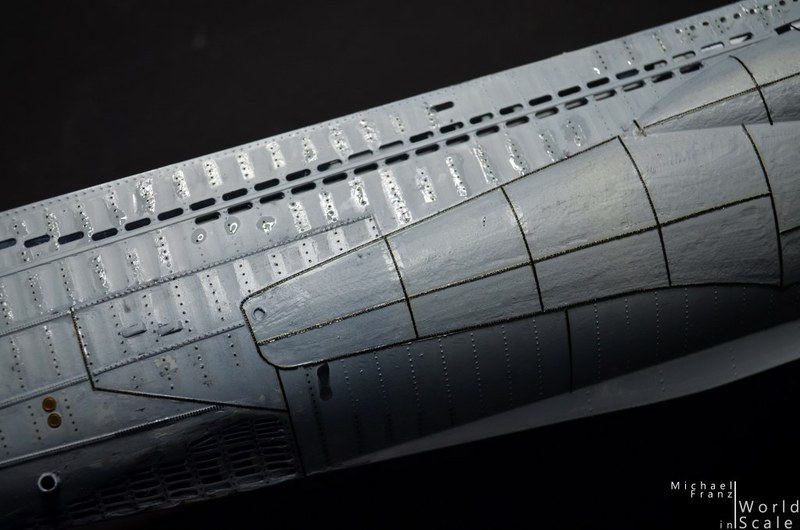

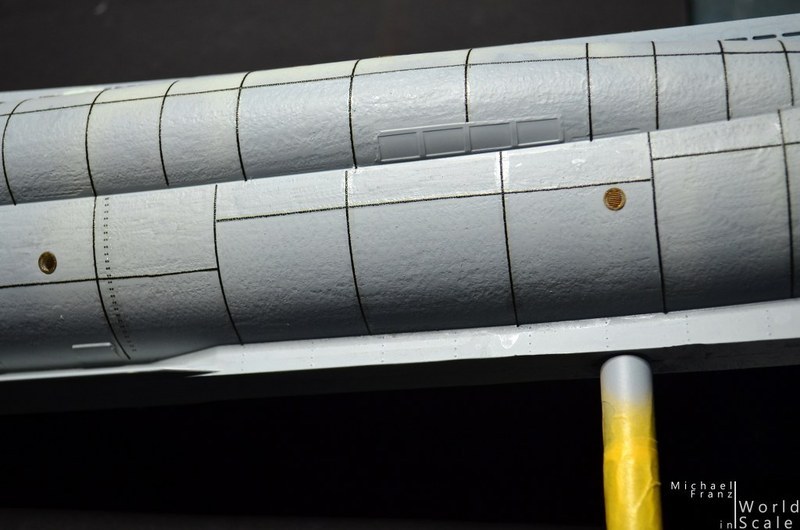

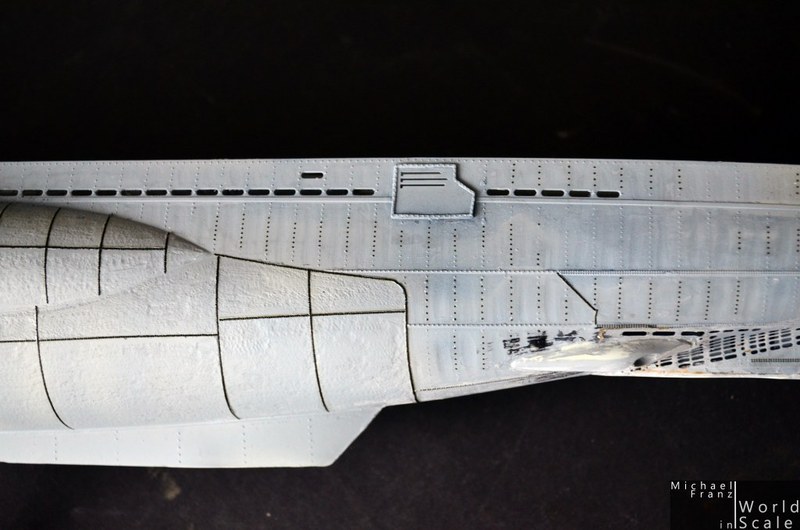

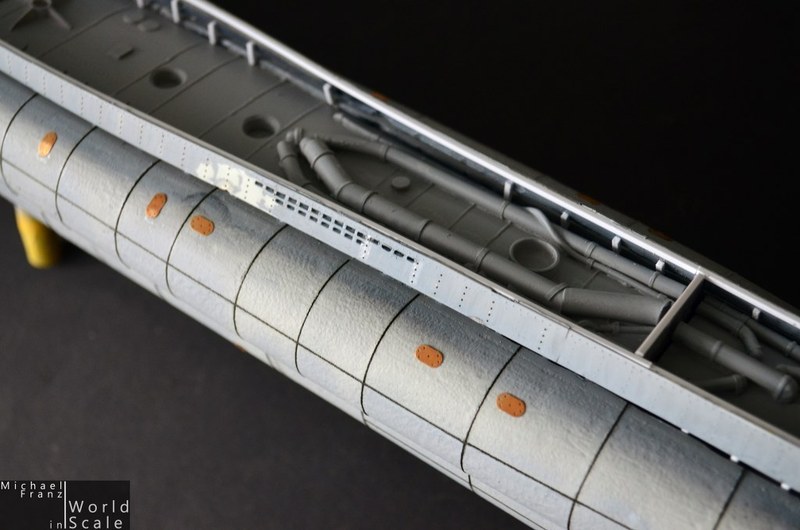

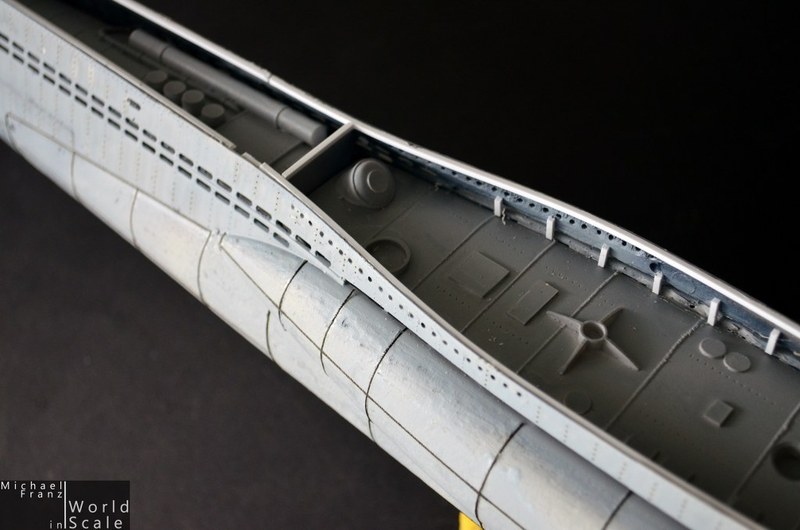

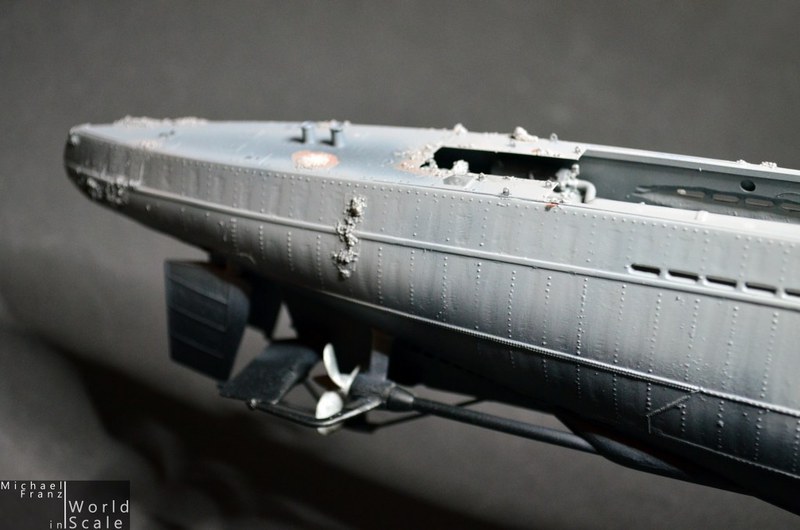

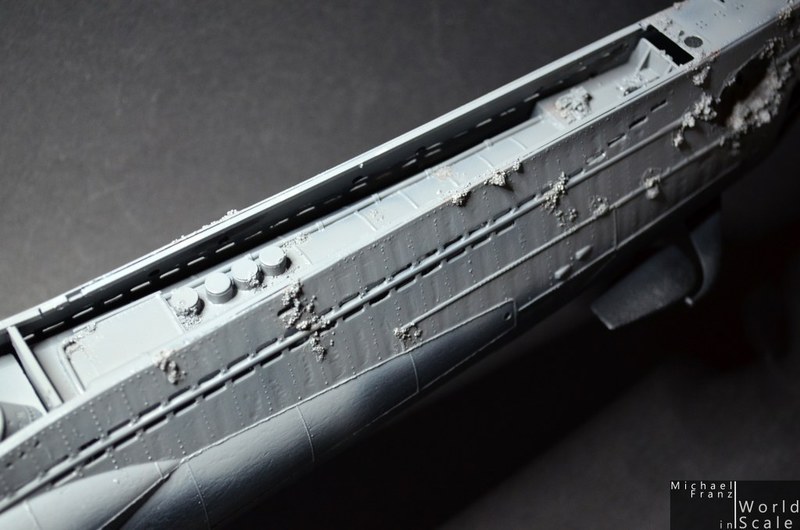

Before we continue with the detailing on the hull I sprayed a first layer of primer on the modifed parts of the hull to see where it needs more putty and more sanding.... Unfortunately (as expected), some further rounds of putty and sanding have to follow before it is a smooth surface....

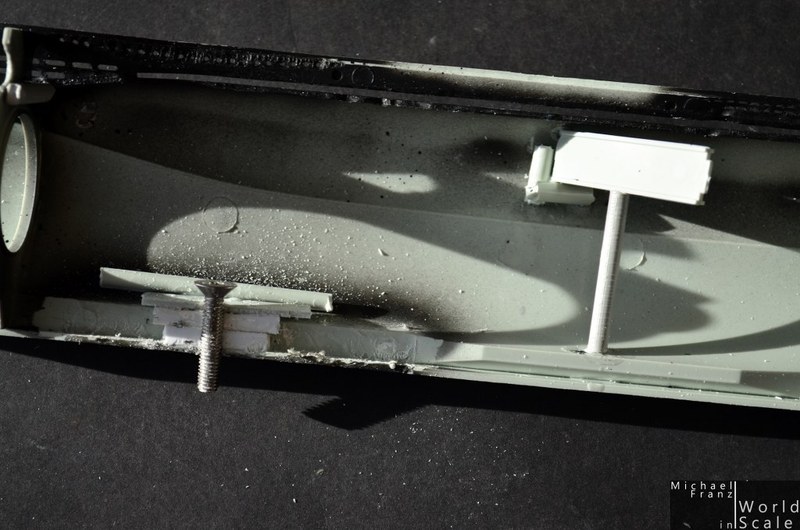

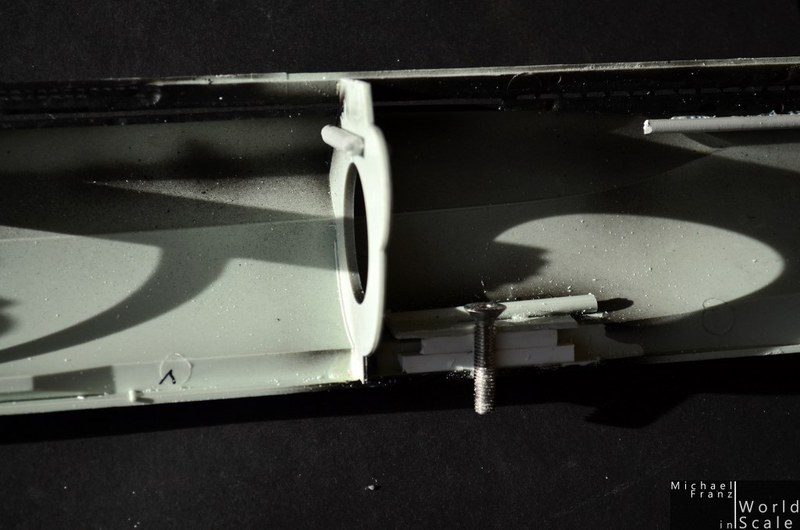

On the inside I glued two wooden parts on the bottom, in which I drilled the holes for the screws, which will hold the boat on the metal display...

But for now.... now I want to wish you and your familiys a MERRY, MERRY CHRISTMAS. Enjoy the holiday season with your loved family! Also thank you very much for your interest in watching this project!

Cheers

Michael