The Type VII was based on earlier German submarine designs going back to the World War I Type UB III and especially the cancelled Type UG, designed through the Dutchdummy company Ingenieurskantoor voor Scheepsbouw den Haag (I.v.S) which was set up by Germany after World War I in order to maintain and develop German submarine technology and to circumvent the limitations set by the Treaty of Versailles, and was built by shipyards around the world. The Finnish Vetehinen class and Spanish Type E-1also provided some of the basis for the Type VII design. These designs led to the Type VII along with Type I, the latter being built in AG Weser shipyard in Bremen, Germany. The production of Type I was cut down only after two boats; the reasons for this are not certain and range from political decisions to faults of the type. The design of the Type I was further used in the development of the Type VII and Type IX. Type VII submarines were the most widely used U-boats of the war and were the most produced submarine class in history, with 703 built. The type had several modifications.

The Type VII was the most numerous U-boat type to be involved in the Battle of the Atlantic

The Type VIIC was the workhorse of the German U-boat force, with 568 commissioned from 1940 to 1945. The first VIIC boat commissioned was the U-69 in 1940. The Type VIIC was an effective fighting machine and was seen almost everywhere U-boats operated, although its range of only 6,500 nautical miles was not as great as that of the larger Type IX (11,000 nautical miles), severely limiting the time it could spend in the far reaches of the western and southern Atlantic without refueling from a tender or U-boat tanker. The VIIC came into service toward the end of the "First Happy Time"[ near the beginning of the war and was still the most numerous type in service when Allied anti-submarine efforts finally defeated the U-boat campaign in late 1943 and 1944.

Type VIIC differed from the VIIB only in the addition of an active sonar and a few minor mechanical improvements, making it 2 feet longer and 8 tons heavier. Speed and range were essentially the same. Many of these boats were fitted with snorkels in 1944 and 1945.

They had the same torpedo tube arrangement as their predecessors, except for U-72, U-78, U-80, U-554, and U-555, which had only two bow tubes, and for U-203, U-331, U-351, U-401, U-431, and U-651, which had no stern tube.

On the surface the boats (except for U-88, U-90 and U-132 to U-136 which used MAN M6V40/46s) were propelled by two supercharged Germaniawerft, 6 cylinder, 4-stroke M6V 40/46 diesels totaling 2,800 to 3,200 PS (2,100 to 2,400 kW; 2,800 to 3,200 shp) at 470 to 490 rpm.

For submerged propulsion, several different electric motors were used. Early models used the VIIB configuration of two AEG GU 460/8-276 electric motors, totaling 750 PS (550 kW; 740 shp) with a max rpm of 296, while newer boats used two BBC GG UB 720/8, Garbe, Lahmeyer & Co. RP 137/c or Siemens-Schuckert-Werke (SSW) GU 343/38-8 electric motors with the same power output as the AEG motors.

Perhaps the most famous VIIC boat was U-96, featured in the movie Das Boot.

[right]Origin: Wikipedia[/right]

NEXT PROJECT ….

The kit by Revell:

Add-on part set by Pontos – etched parts, turned brass, resin, wooden deck:

Resin-set for detailing the pressure hull by Blue Ridge Models:

Main gun made of resin by Eduard:

[u]First Stepp, detailing the surface of the hull[/u]

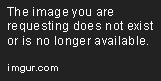

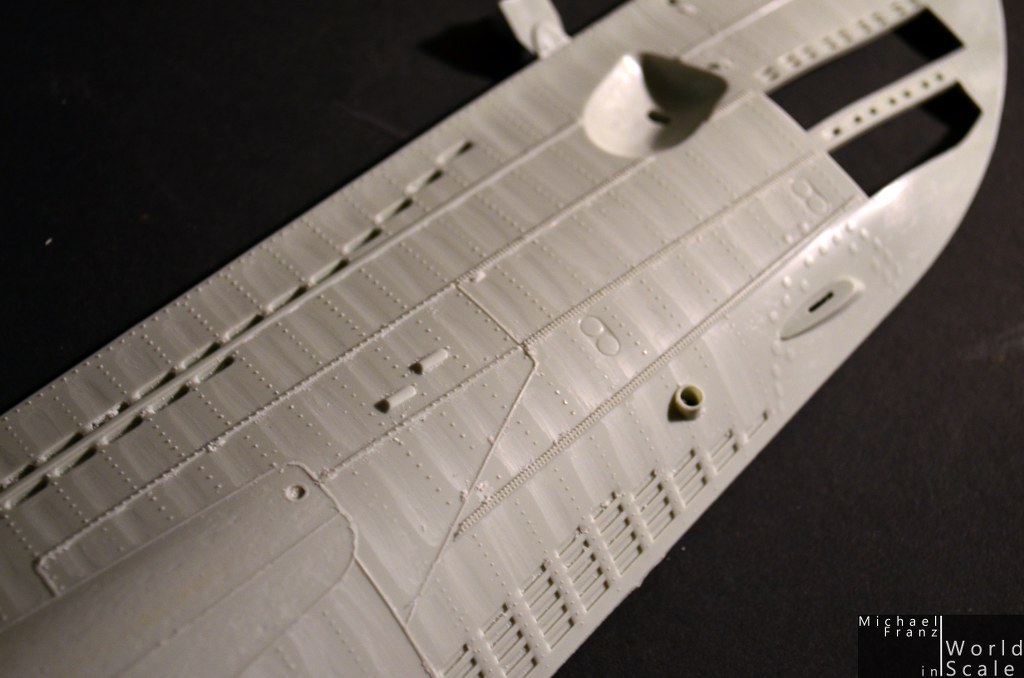

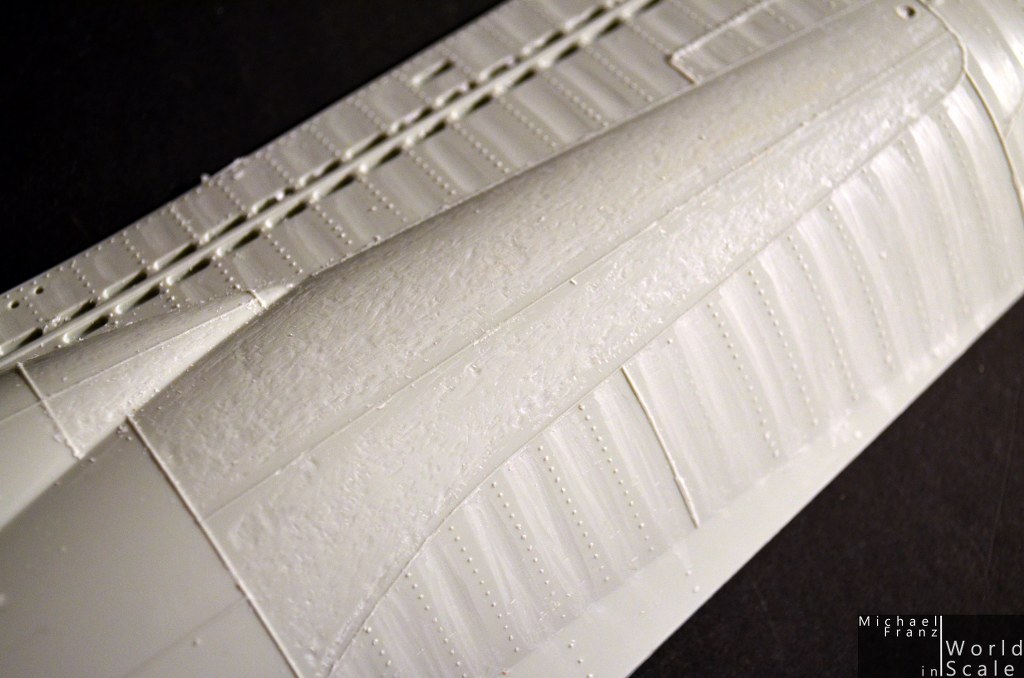

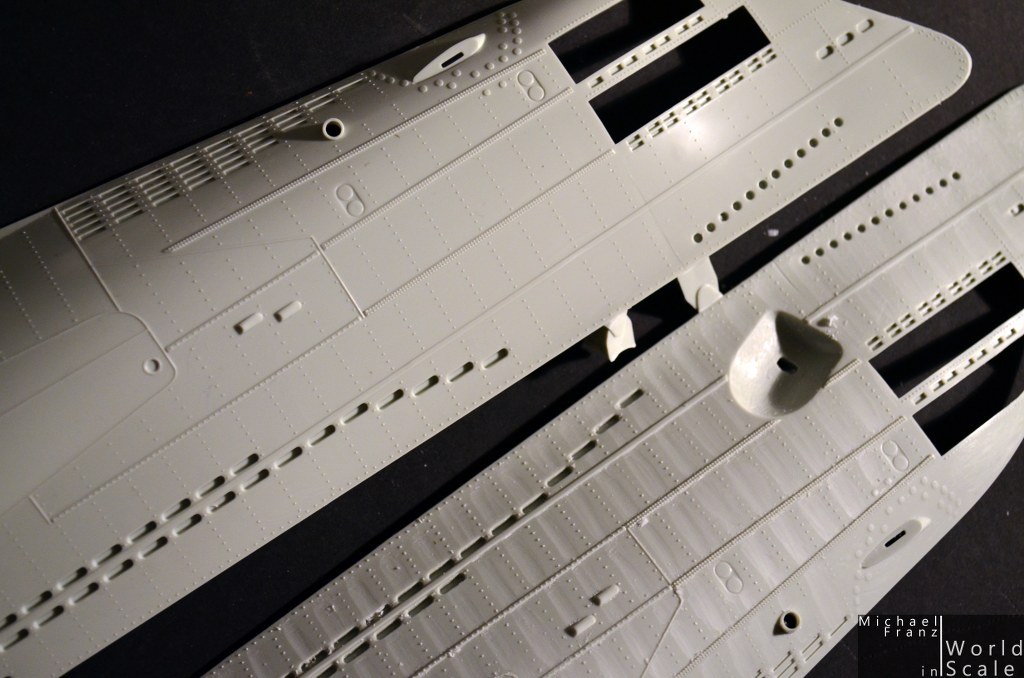

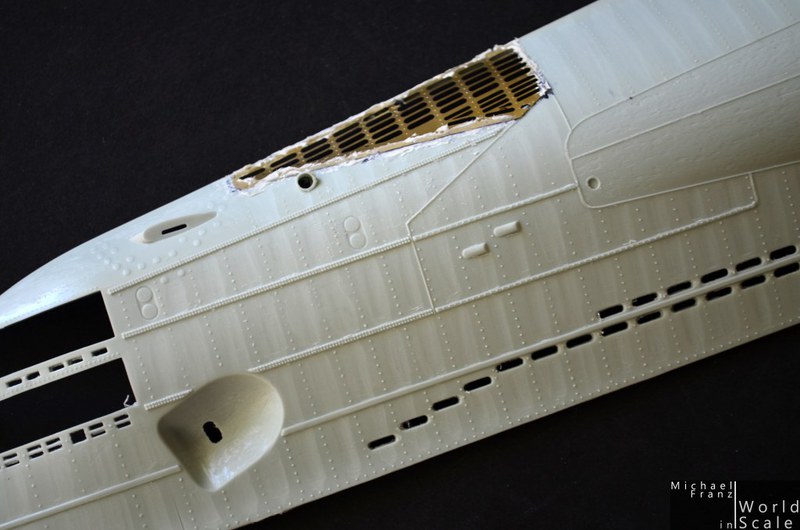

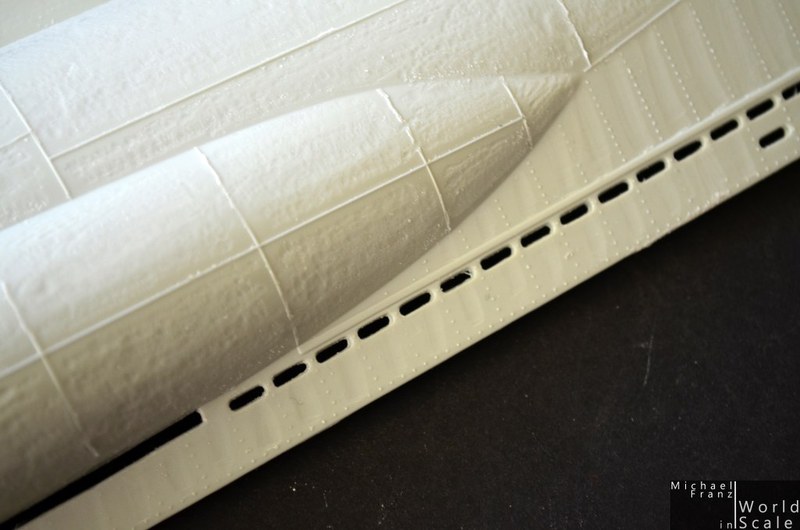

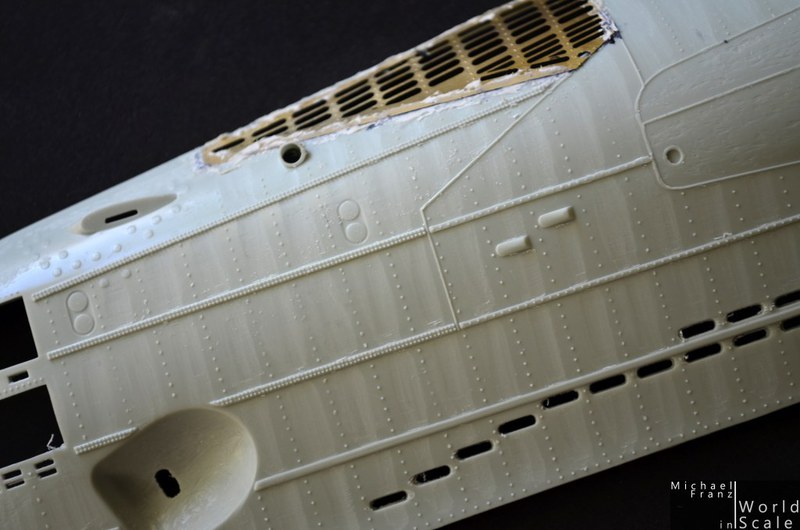

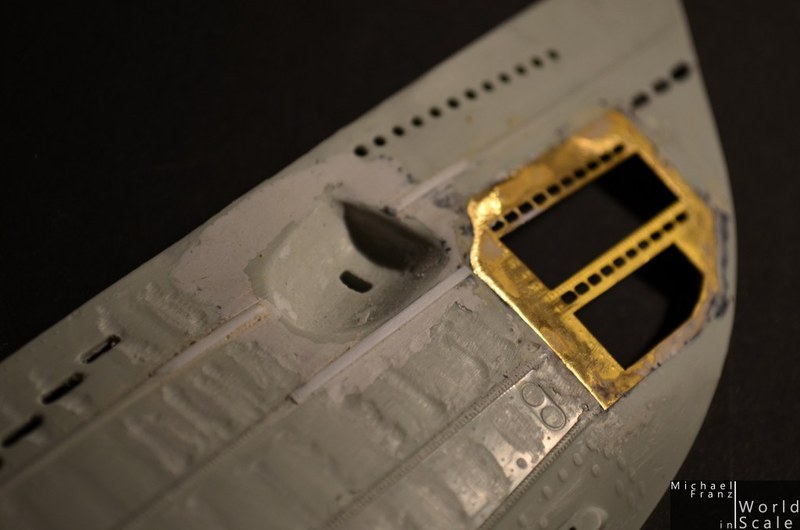

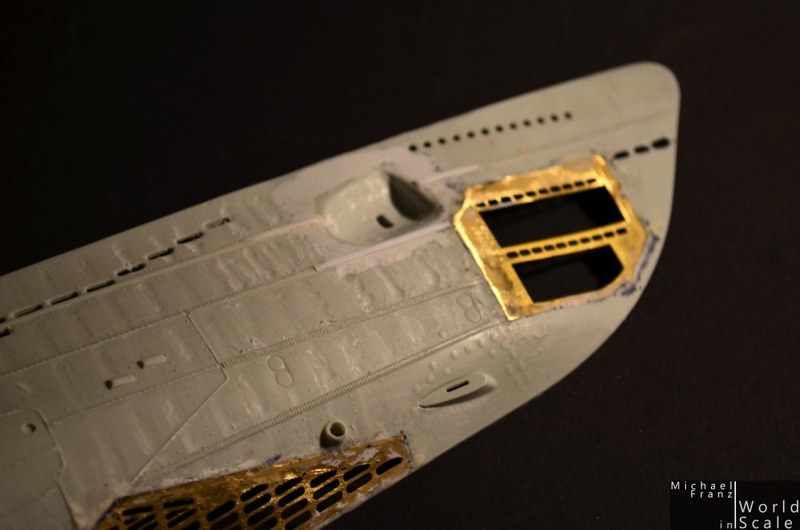

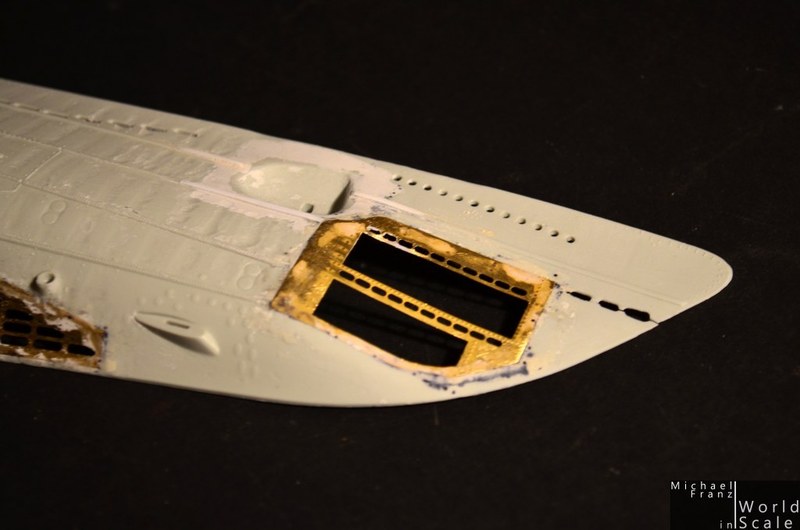

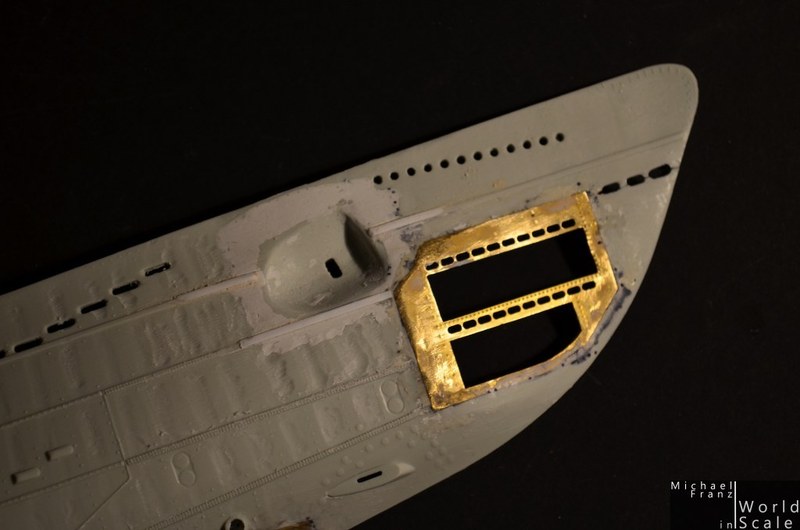

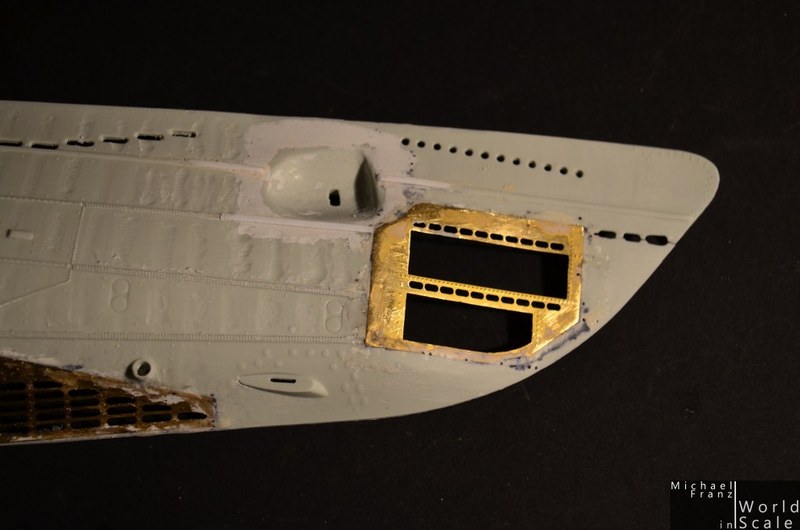

The two main parts of the hull are very well detailed by Revell with several rivets and more. The typical surface of the hull of an U-Boat, long times under water with high external pressure is missing. I think it would have been difficult to make it for Revell.

(Quelle: Wikimedia)

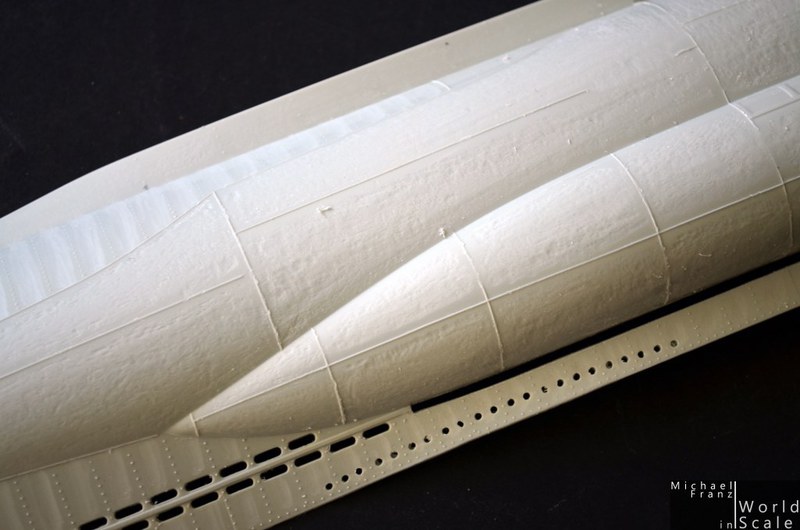

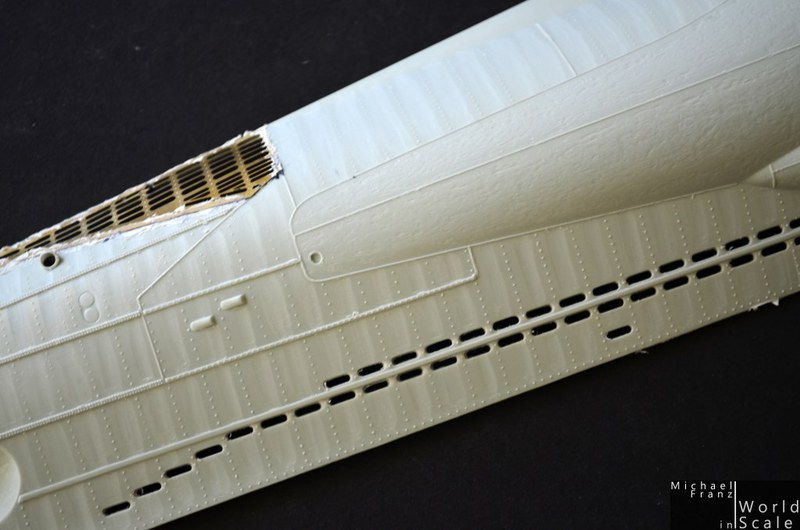

I wanted to show this here and tried several ways. Finally I started, equipped with my hobby knife and a round blade, scratching each “Steel plate” on the hull, between the rivets deeper…. The bigger steel plates at the pressure hull were reworked with a cutter / mill in my dremel…. Worked on the surface to get a realistic surface. As last step I will sand the full hull once again with a fine sanding paper – always taking care that the rivets remain undamaged.

Pictures of the reworked parts follow, with the unmodified plastic part as comparison!

Cheers

Micha