Here are two pictures of my fiancee holding the box and hull (she's 5'6" tall). The hull measures a little over 40" long and 6" wide, so this is no small model.

References:

There are lots of other references being used from various magazines, etc., but my main points of reference for this build are (L-R): Anatomy of The Ship: The Battleship Yamato, Iron Battle Wagon Model Graphix Navy Yard Special Issue, Model Art Super Illustration IJN Yamato, Model Art Modeling Guide IJN Yamato, Gakken IJN BB Yamato & Musashi.

Materials:

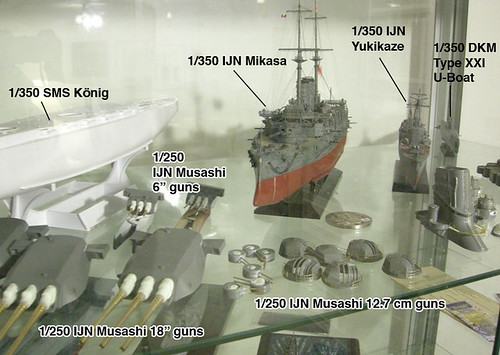

Arii/ Otaki 1/250 IJN Musashi

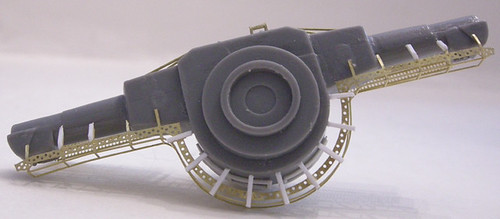

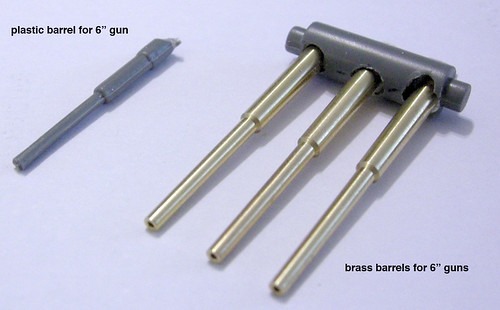

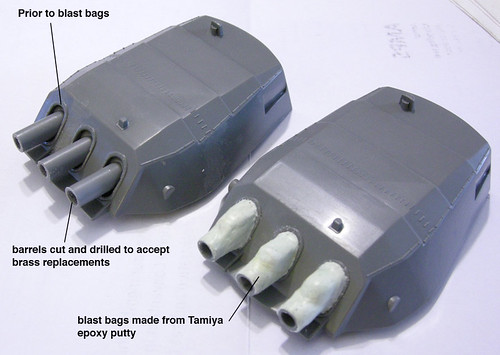

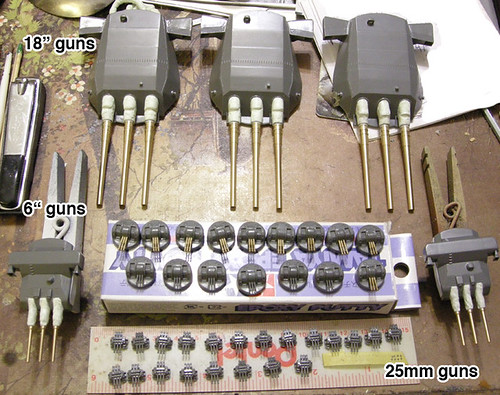

Fukuya 1/250 IJN Yamato Class Main & Sub Gun Barrel (15pcs.)

Fukuya 1/250 IJN Yamato Class AA Gun Barrel (24pcs.)

Fukuya 1/250 IJN Yamato Class 25mm Machine Gun (30pcs.)

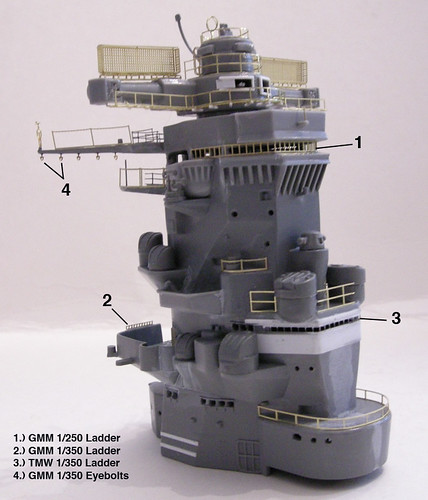

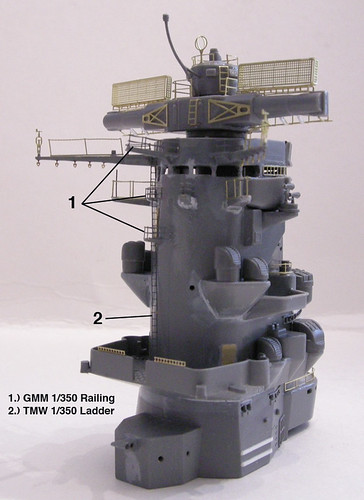

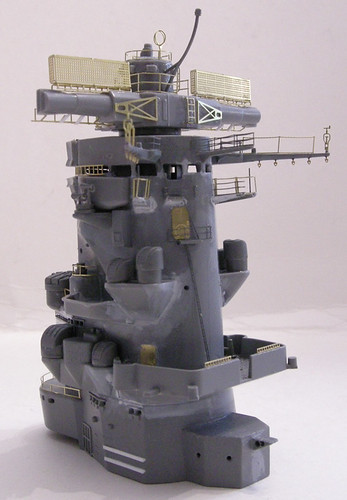

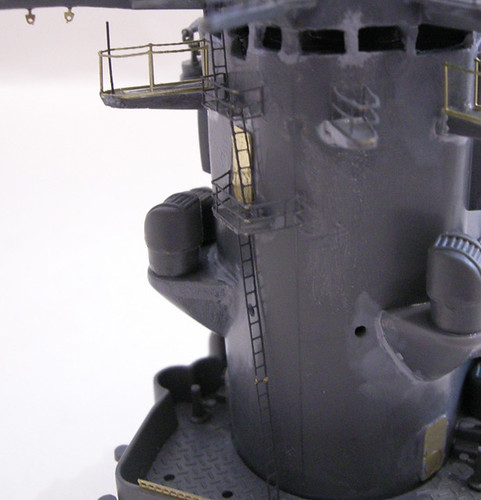

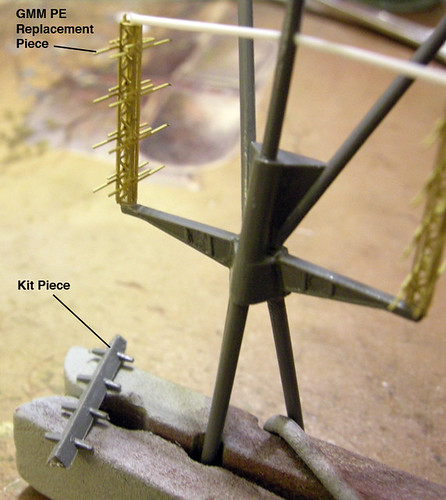

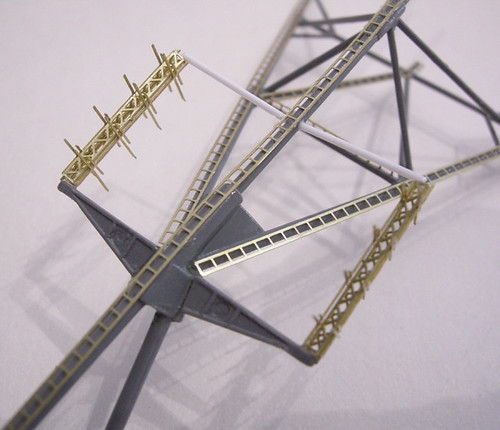

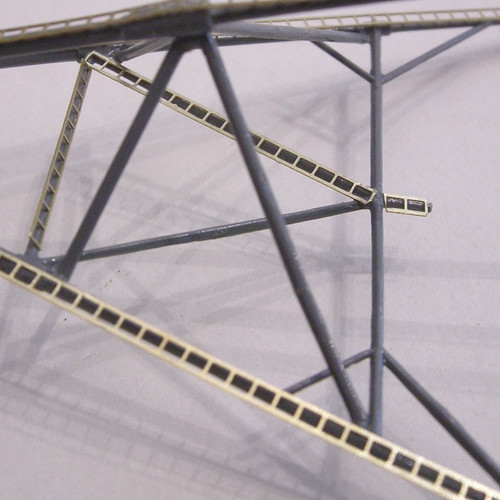

Gold Medal Models (#250-6) 1/250 scale YAMATO / MUSASHI Photo Etch

Gunze Sangyo H-83 Dark Grey 2 (x12) for all above waterline gray

Gunze Sangyo H-33 Russet (x6) for waterline down

Gunze Sangyo H-79 Sandy Yellow (x4) for wood decking

Various thicknesses and widths of Evergreen plastic strip and rod

Building:

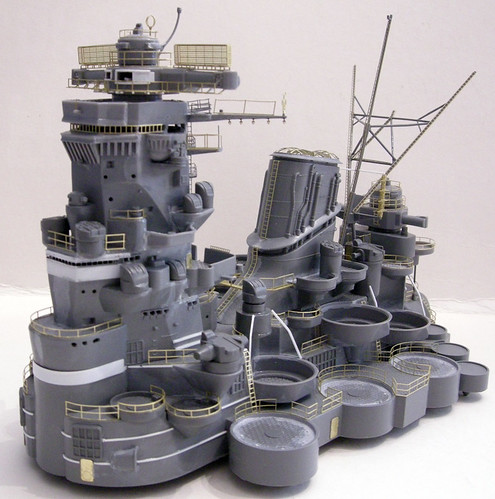

Let me state right away that this build is all about "presence" rather than scale accuracy. Part of the appeal of this build is the size of the model and I wanted to build her in a way that adds to the most striking aspects of this beautiful ship. I can debate the rivet counts of IJN ships with the best of them, but that isn't the aim of this build. Even the 1/10 scale Kure model has debatable faults, so if you're looking for a dissertation of scale perfection, I advise you to go elsewhere. This is all about "presence" and "perception", if you will.

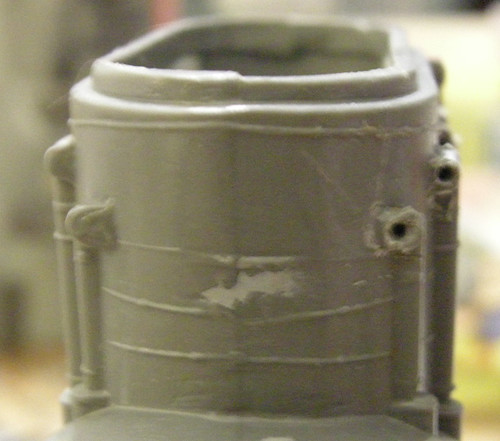

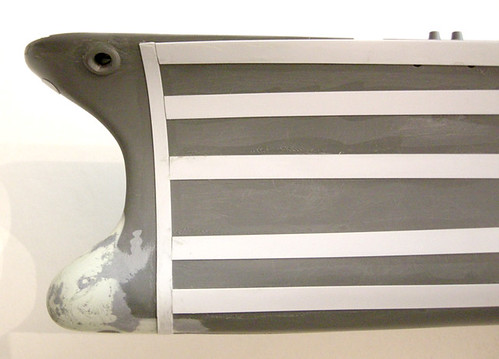

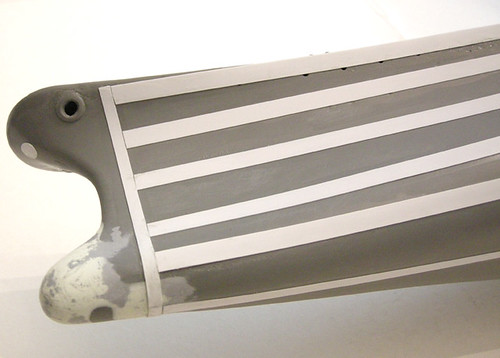

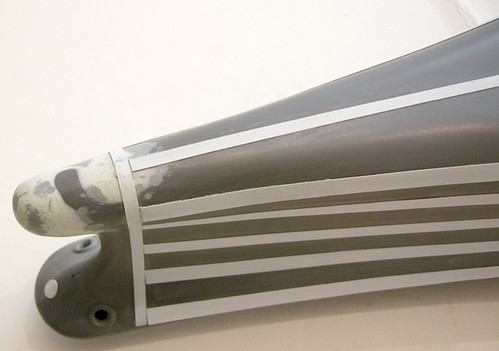

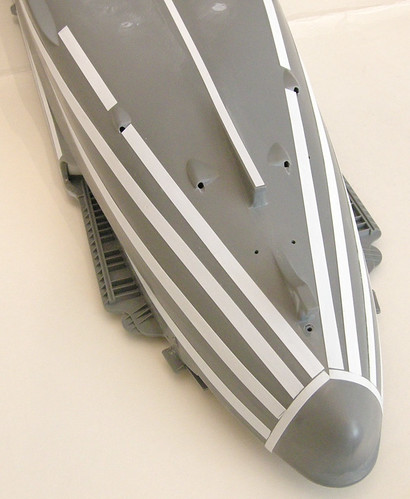

The biggest modification I made was to the bow area. The model's bow is actually too small, so even if you're going for scale accuracy, surgery is required. I decided to make mine just a little larger than accurate to enhance the powerful feel that the prow of this ship contains. I also made the curve between bow and prow more pronounced by grinding out the center area a bit more. The bow was built up with Tamiya Epoxy Putty and filler putty until it had the look I wanted. I also added the fore drain surround, but haven't drilled it out yet.

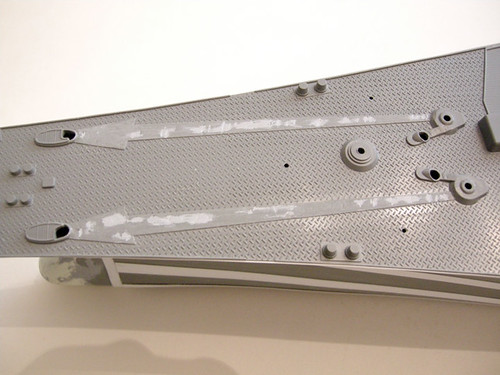

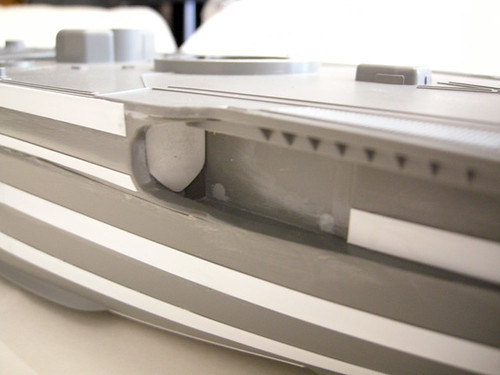

Another addition is the plating along the hull. I sanded off all details from the already fairly smooth hull and added styrene strip. I still have to do some putty work and rounded area pieces (bilge keels, bottom, etc.) in these pictures. The molded on degaussing cable was removed to be replaced with a new one. The molded on anchor chain has been sanded off for real chain.

You may notice that there is more space between the third and fourth plates from the top. While this looks "off" without paint, it takes into account the waterline and will look fine after painting.

I knew from the beginning that I wanted a nice base made of oak for this project. A call to my father, a master carpenter who I always beg bases from, with some measuring and a nice base was the result.

To keep the model stable, another piece of oak was mounted in the hull and secured with screws put into the bottom. The light gray circles are where the screws have been puttied over. Metal rods in the base slide up into the holes and weight and friction keeps the model secure. Once the hull has been painted and weathered, it will be placed on the base permanently.

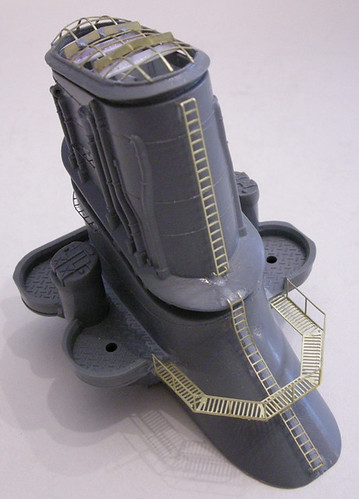

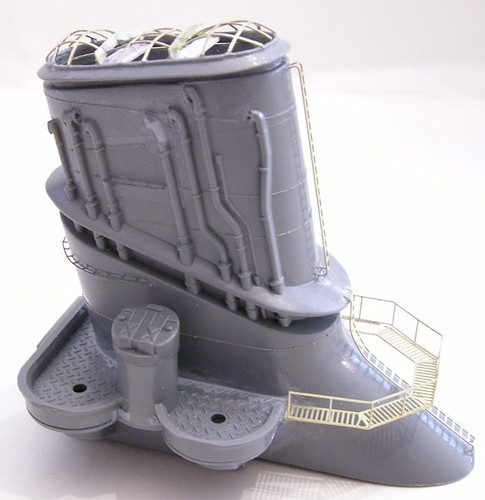

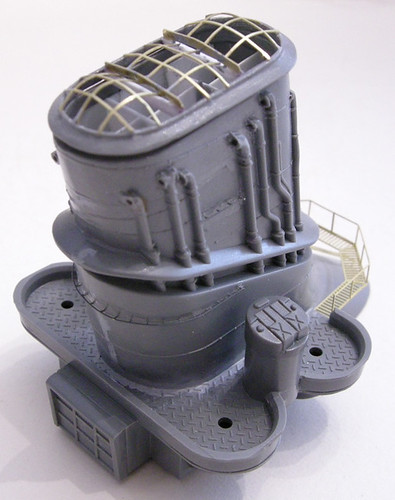

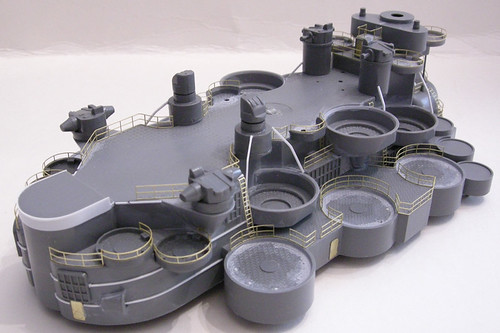

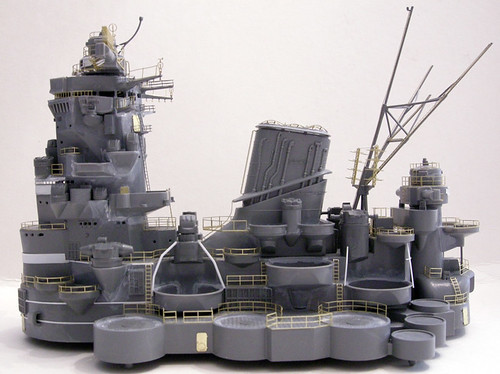

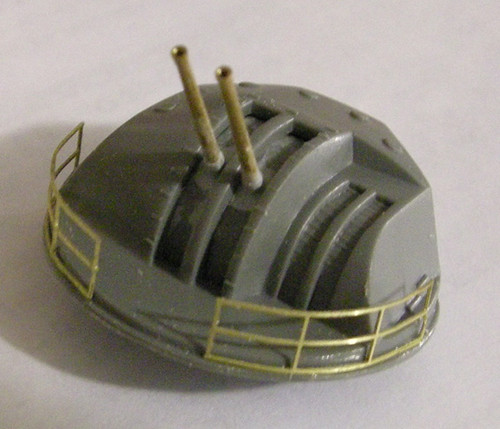

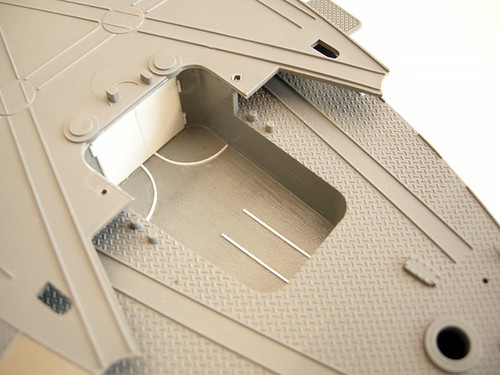

Jumping around to various parts of the ship as others dry, I added some detail to the hanger area. The kit just had a simple box area, so I added doors, rails, and some texture to the floor area. The doors for the rear boat hangars were also added.

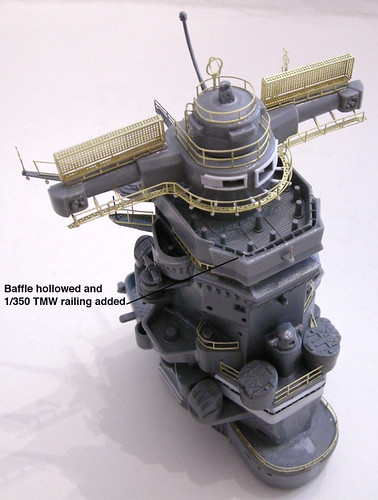

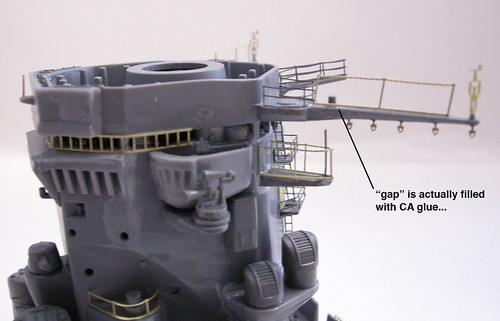

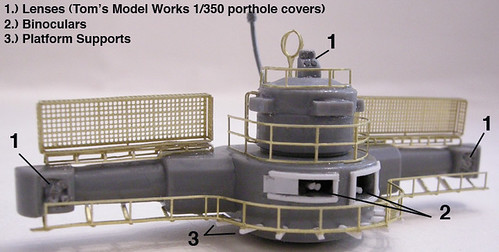

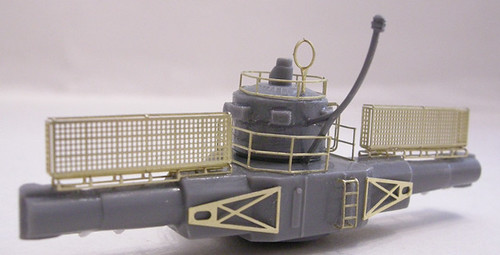

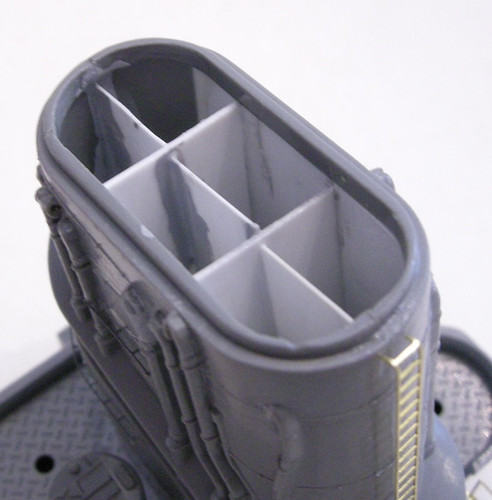

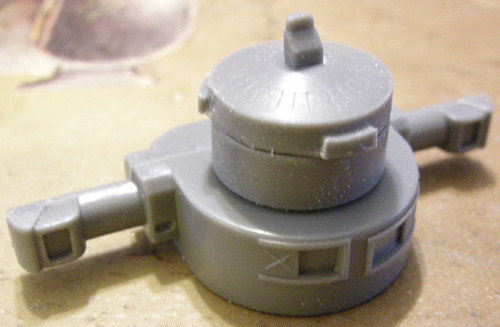

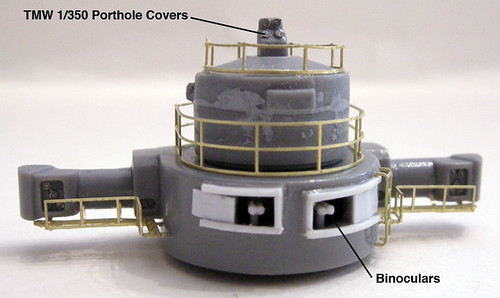

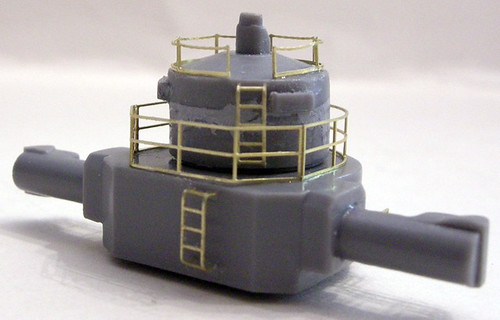

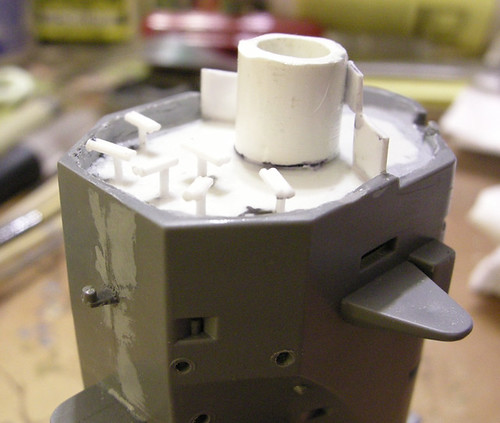

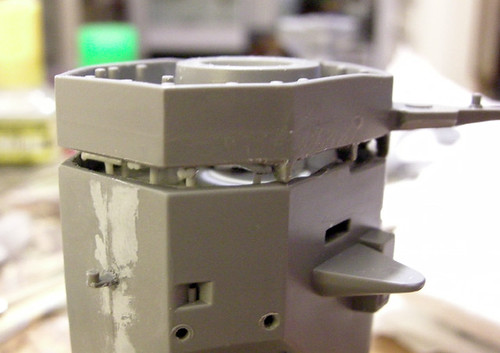

All port holes will be drilled out as they have been on the superstructure. The bridge area looks nice, but the top most interior spotting area was solid, so I carved out the place and added floor, central structure, rear walls, doorways, and binoculars. After the top piece is glued on, I'll add the window sills and Krystal Klear for glass.

That's all for now. More at some point as build time permits. I'm shooting for this to be entered in the Orlando Modelpalooza in May, so we'll see what happens...