SInce I'm a ship newbie this build log is meant to show progress as well as solicite suggestions/advice for the build process. The super-set PE arrives on Wednesday and I still need to get the the other sets. FOr now I'll do some cleanup on the hull to get rid of the mold lines and the visible ejector pin marks on the bottom of the flight deck.

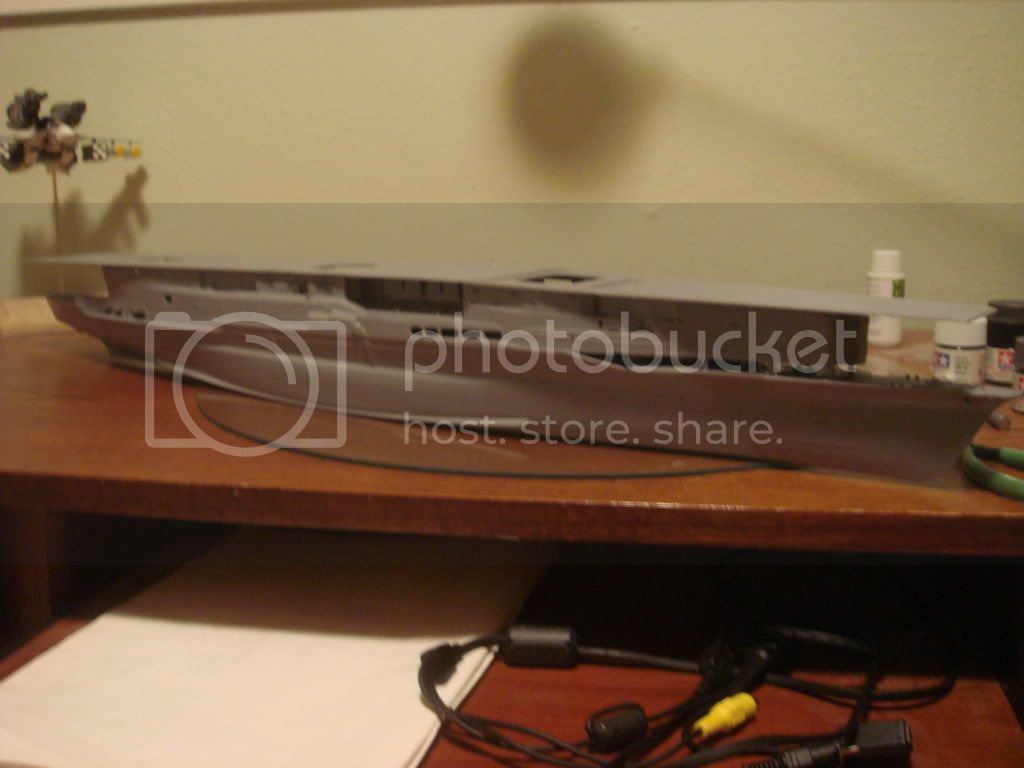

Here are some pictures of the beast with the hull halves, structural strengtheners, and the flight deck dry-fitted. A most impressive site

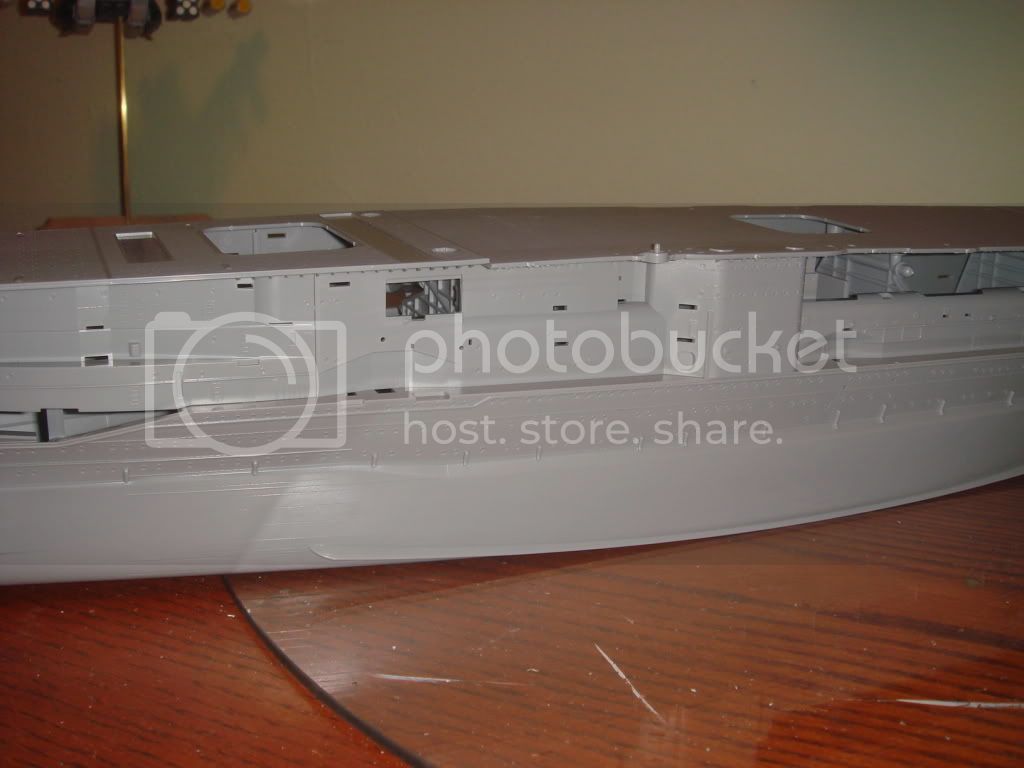

How the thing looks with all of the internal bulk-heads

The ejector marks under the flight deck

Areas where sub-assmblies will have to built, painted, weathered, and installed before the hull halves can be assmebled

Starboard area below the funnel

Boat deck under the flight deck, just in front of the open stern boat deck.

I wouldn't noticed the mold lines on the hull halves if left to my own devices. Thanks to Tracy White over at ModelWarship.com for his review of the kit.

That's it for now. Some sanding and filling to do before the deck PE gets here.