I have been working on this model for over a year now and I say prolly another 5 months to complete.

So, here we go:

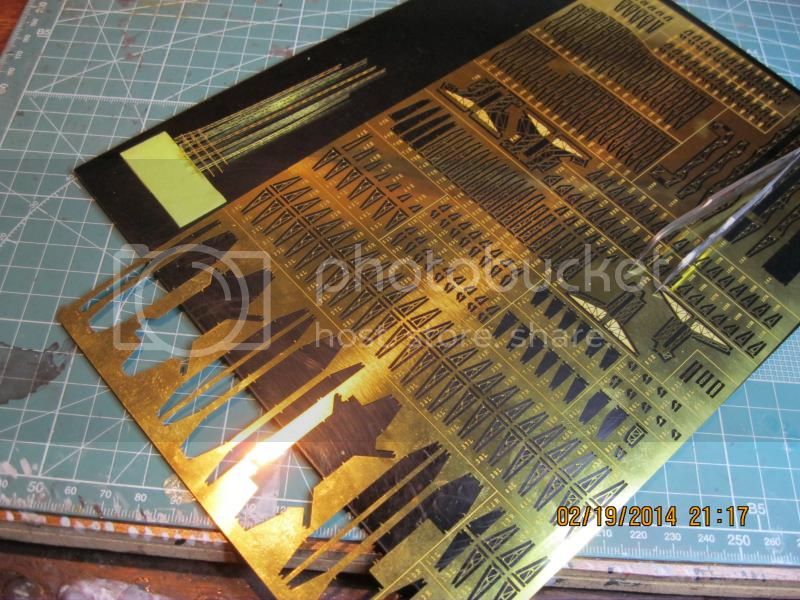

Kit + some of the pe and one box of four of planes

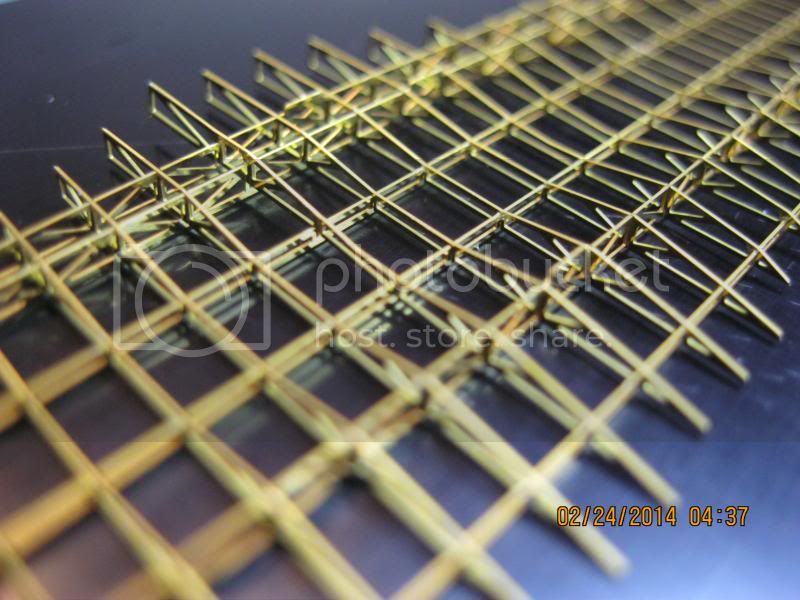

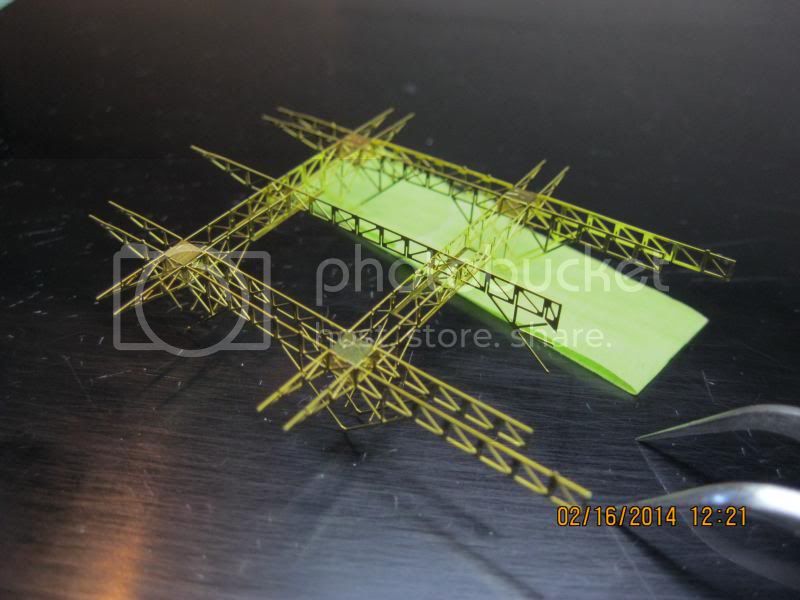

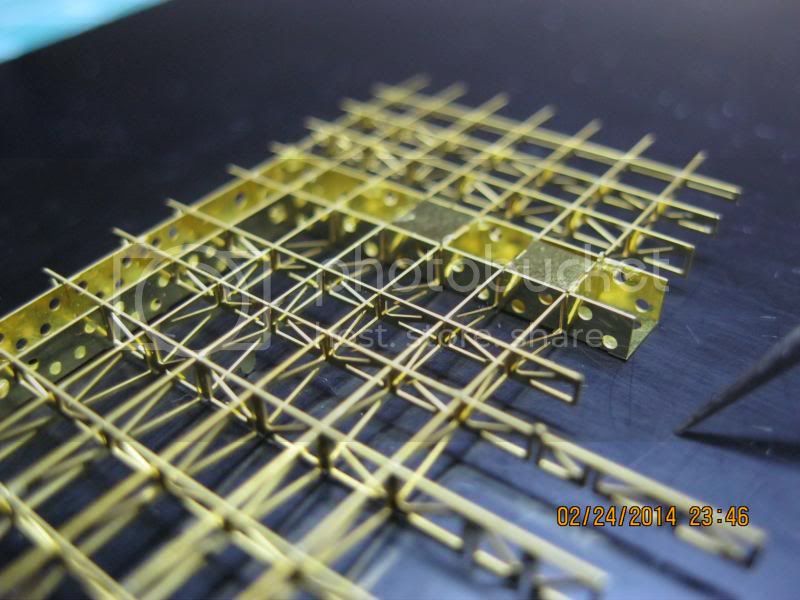

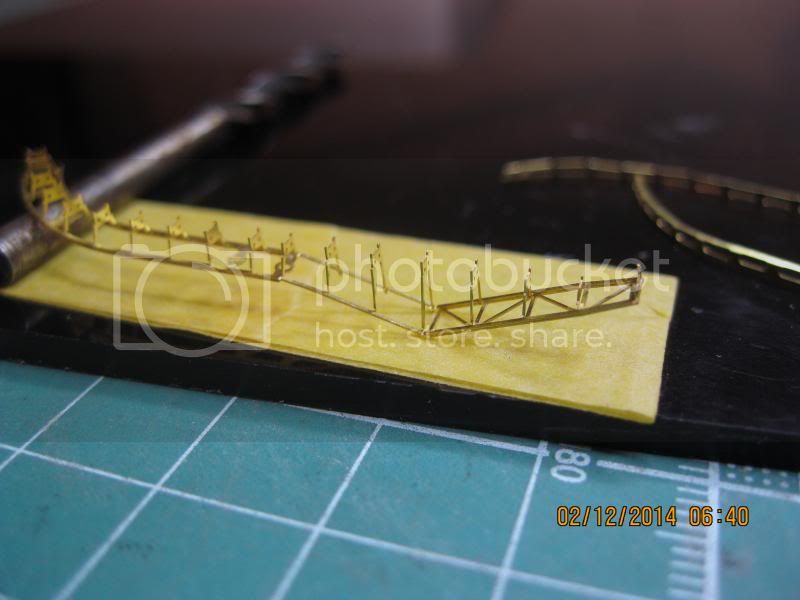

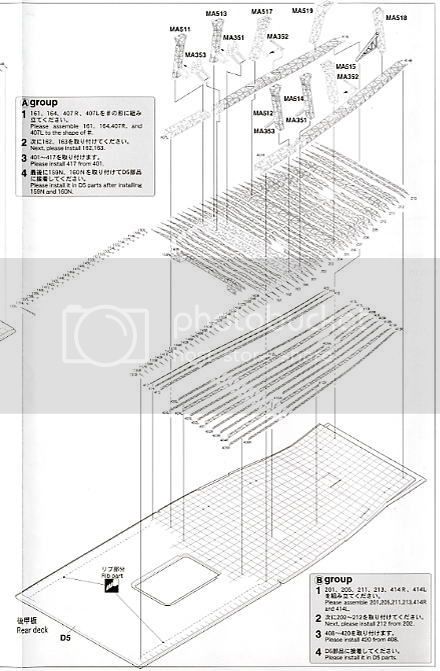

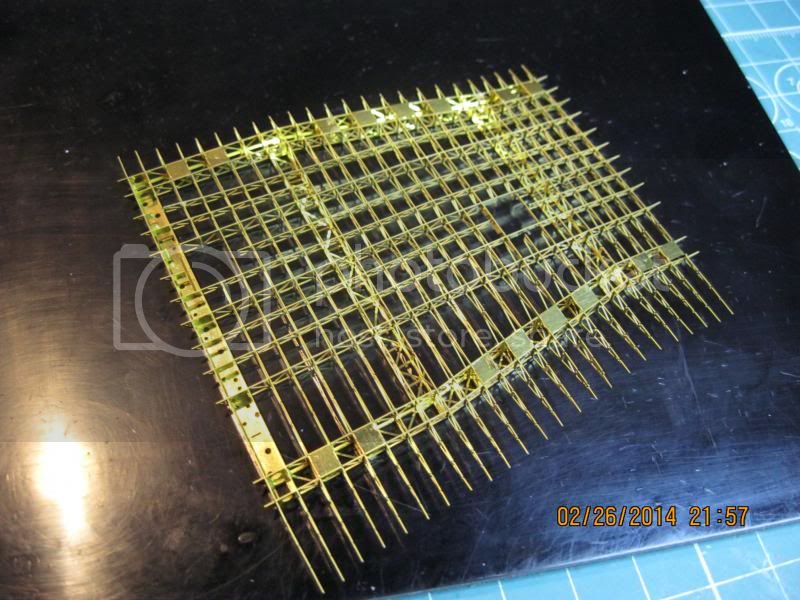

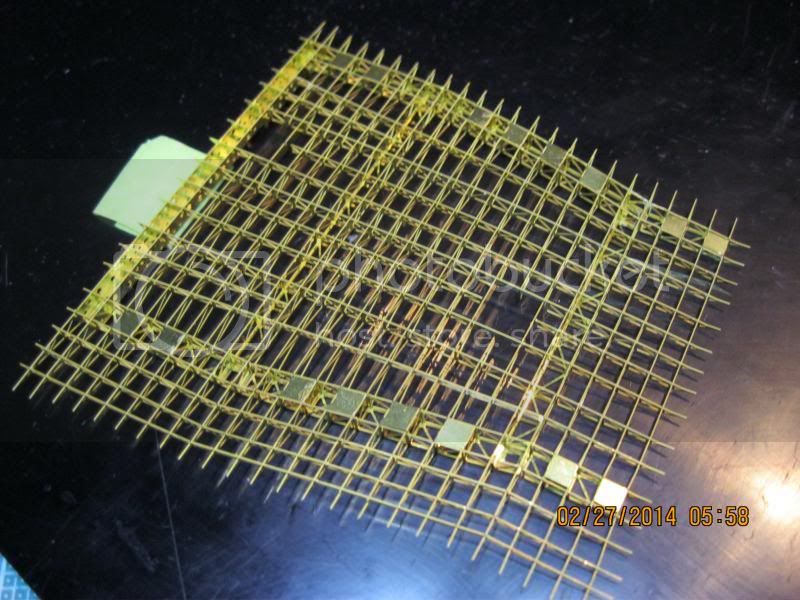

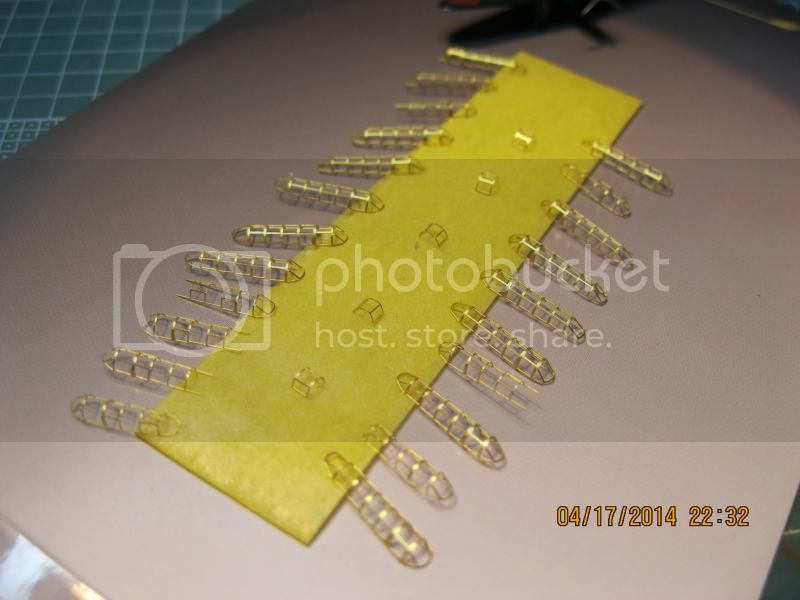

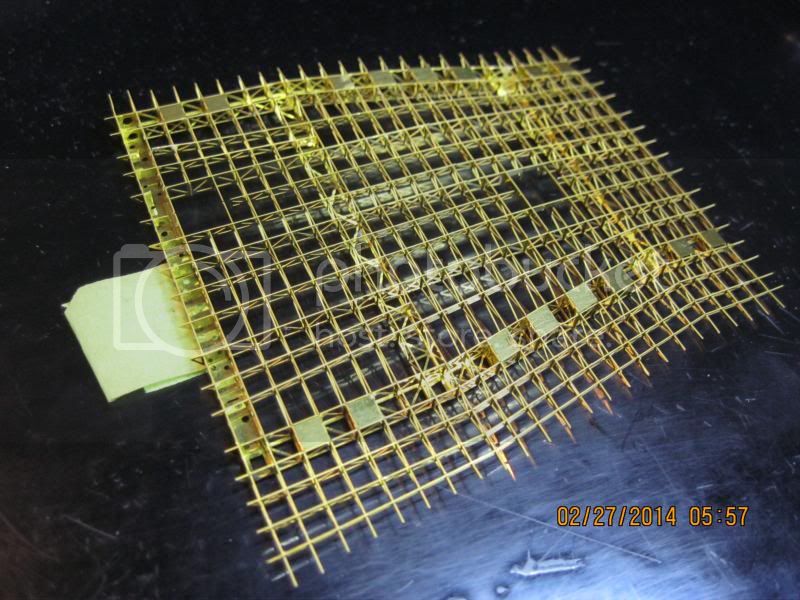

Hasegawa Super Detail-up Package (Underdeck supports, columns and tramways)

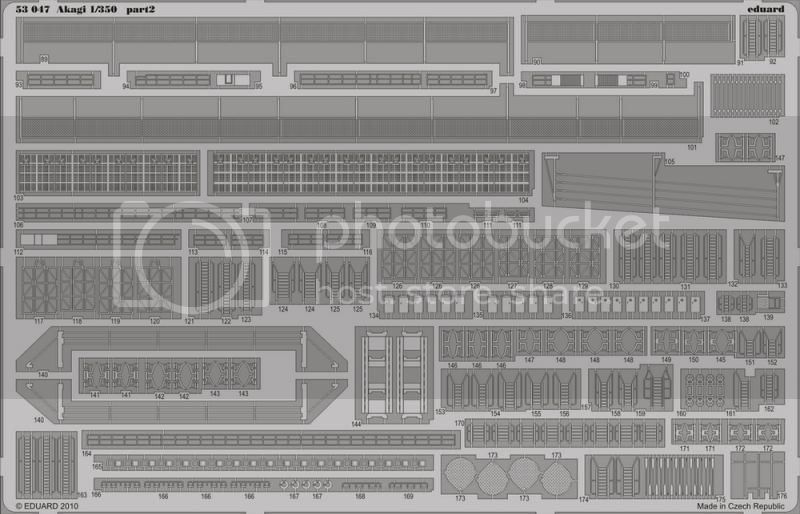

I am also using the Eduard 1/350 Akagi set to supplement

I have 4 boxes of the Hasegawa airplane sets

Wood deck and dry transfer set from Hasegawa

Utility boat detail set

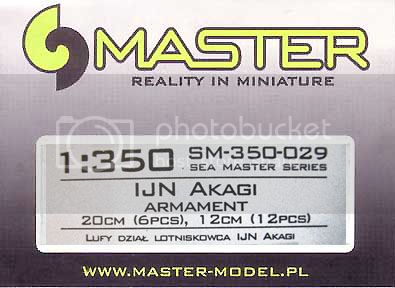

Plus other and various pe/aftermarket stuff including Master's brass barrel and armament set

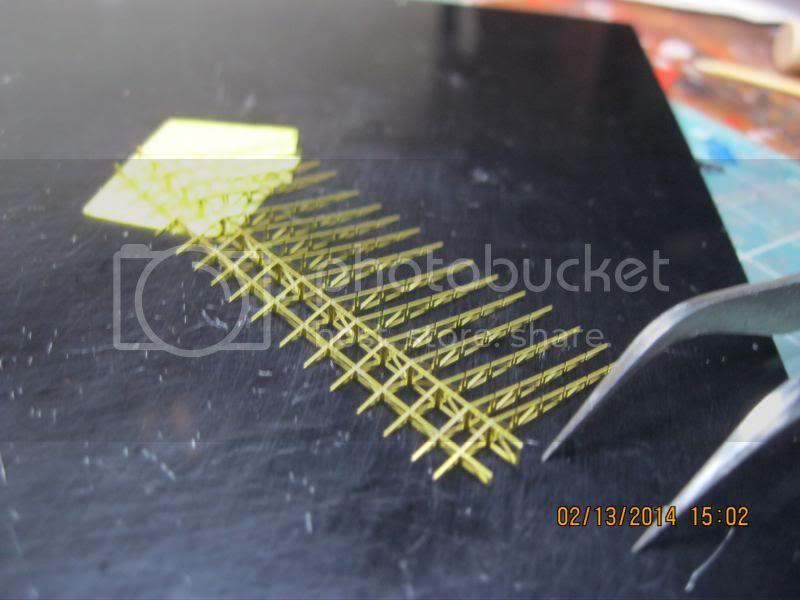

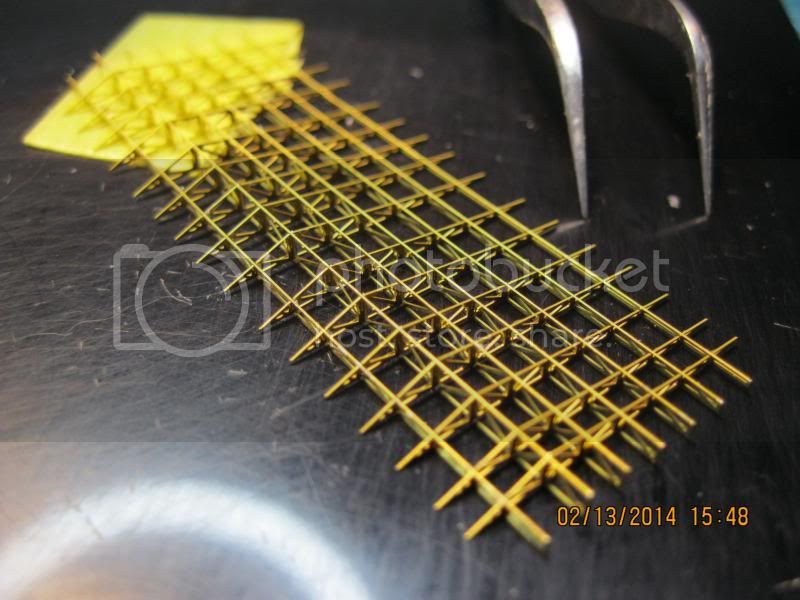

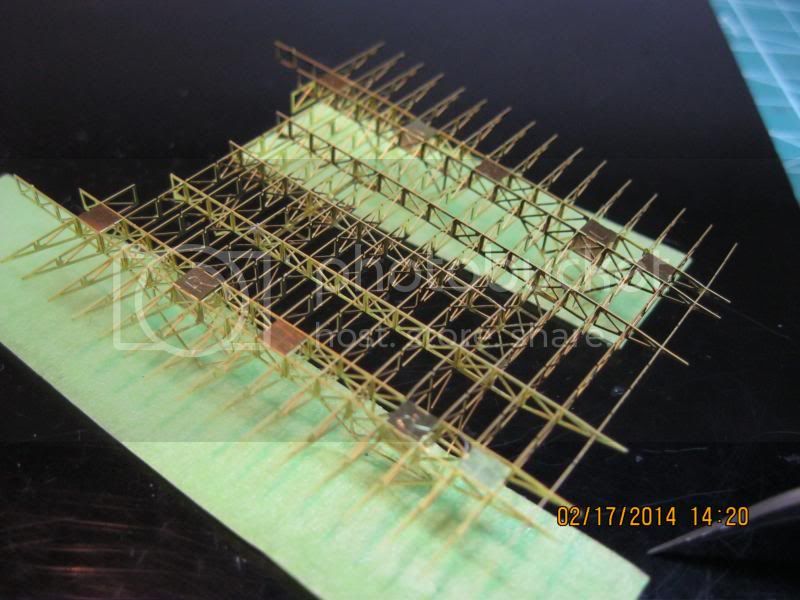

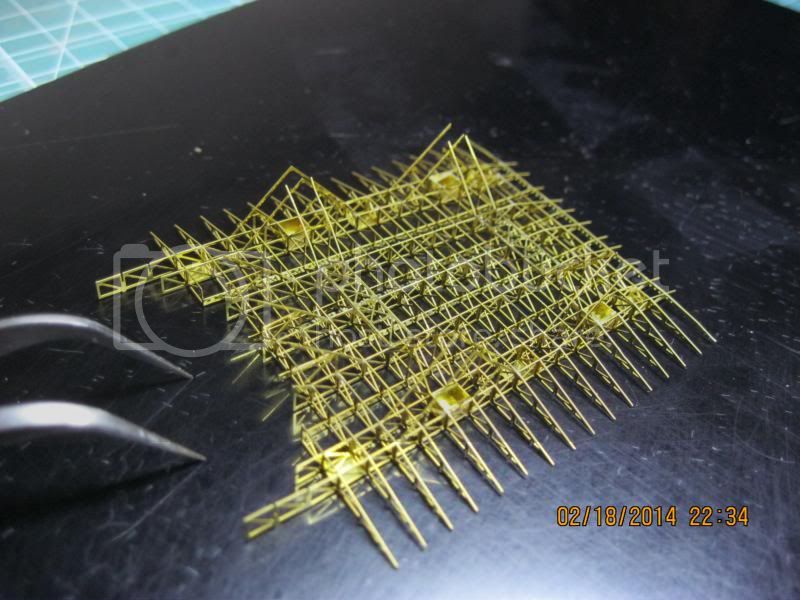

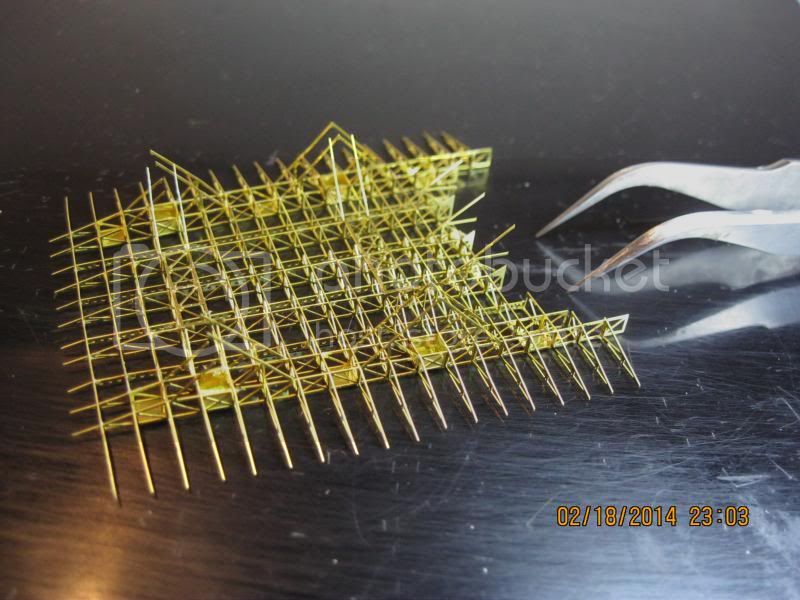

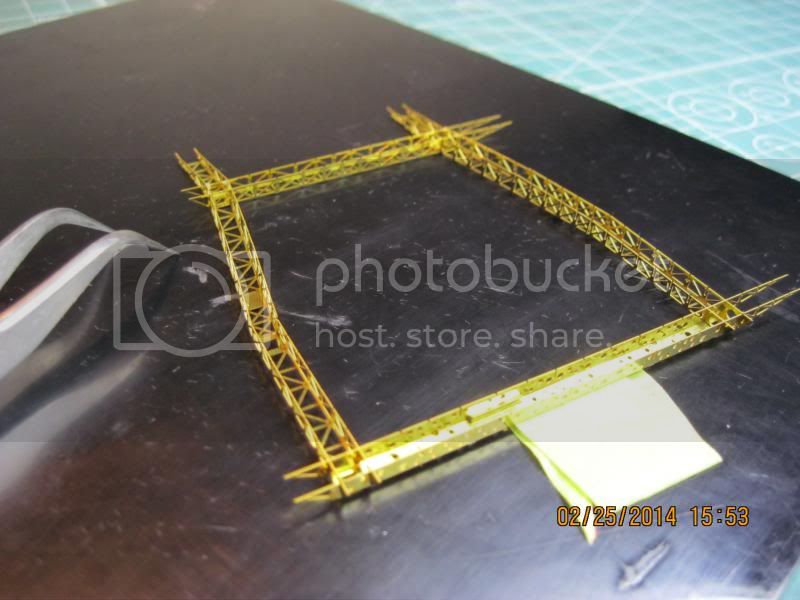

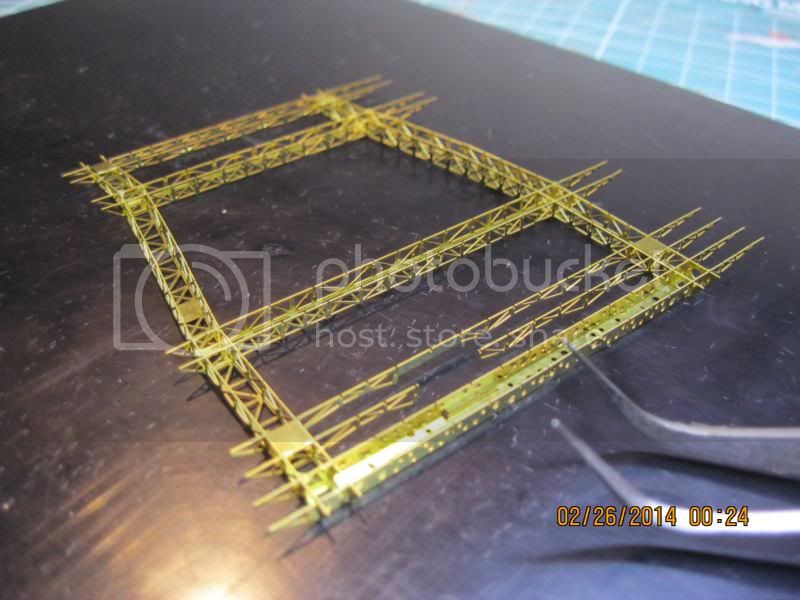

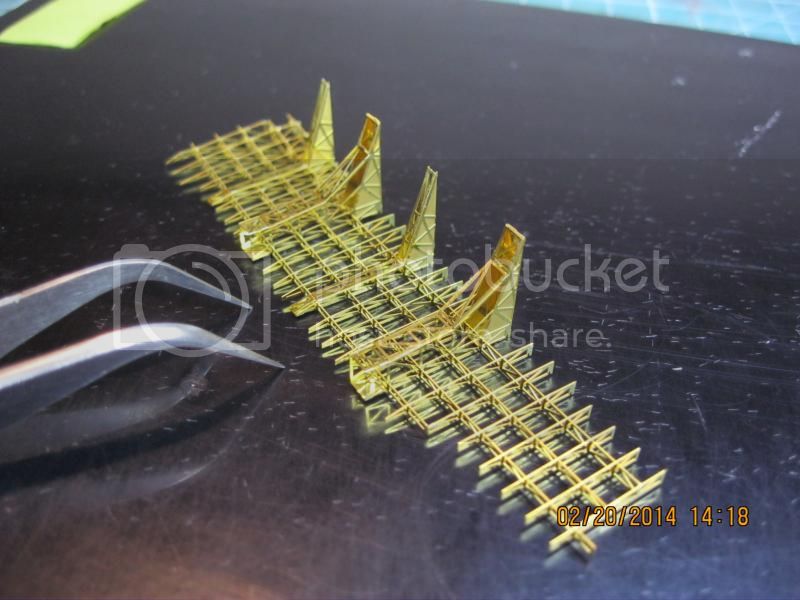

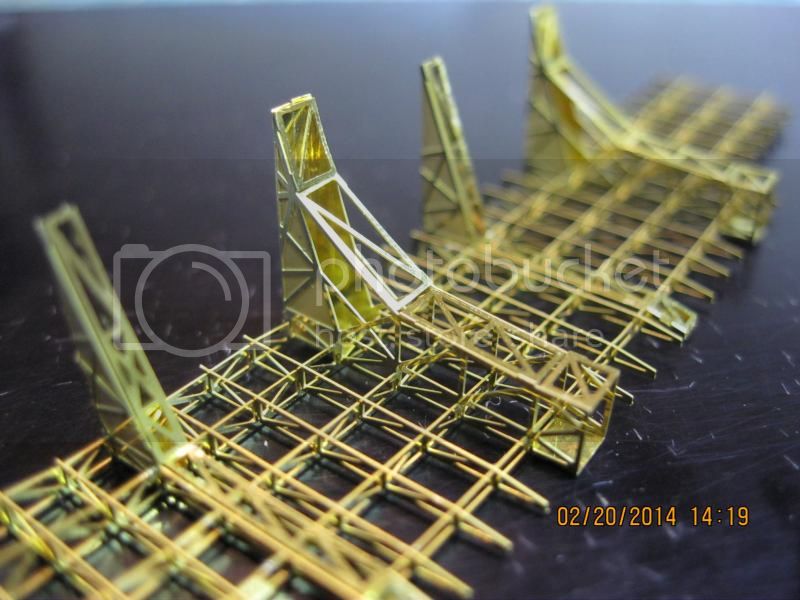

You will probably see many followup posts from me rather quickly over the next week or so as I have many of the modules done, including the underdeck supports... one of which I have included here as a preview:

Cheers and thanks for joining me for my upcoming Akagi build on ModelShipwrights! -Tim