Yesterday's progress.

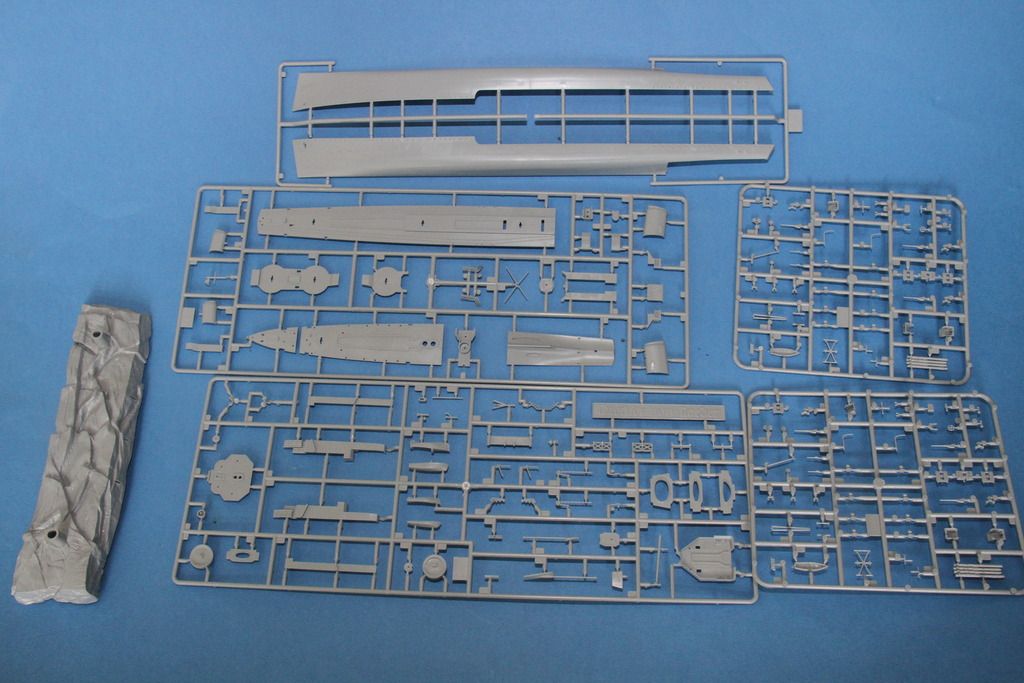

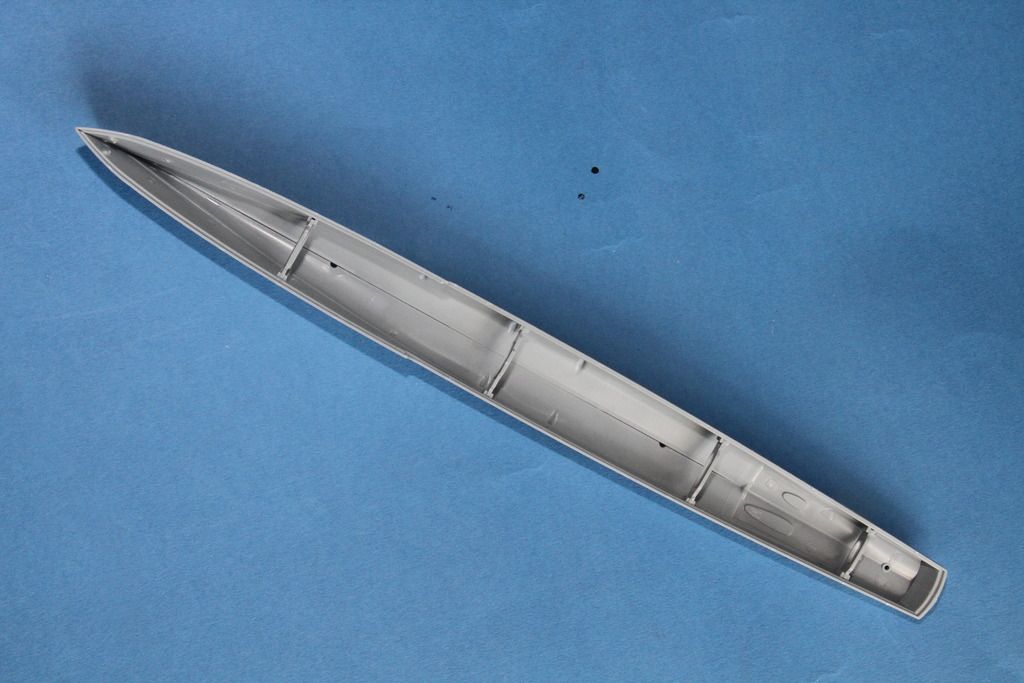

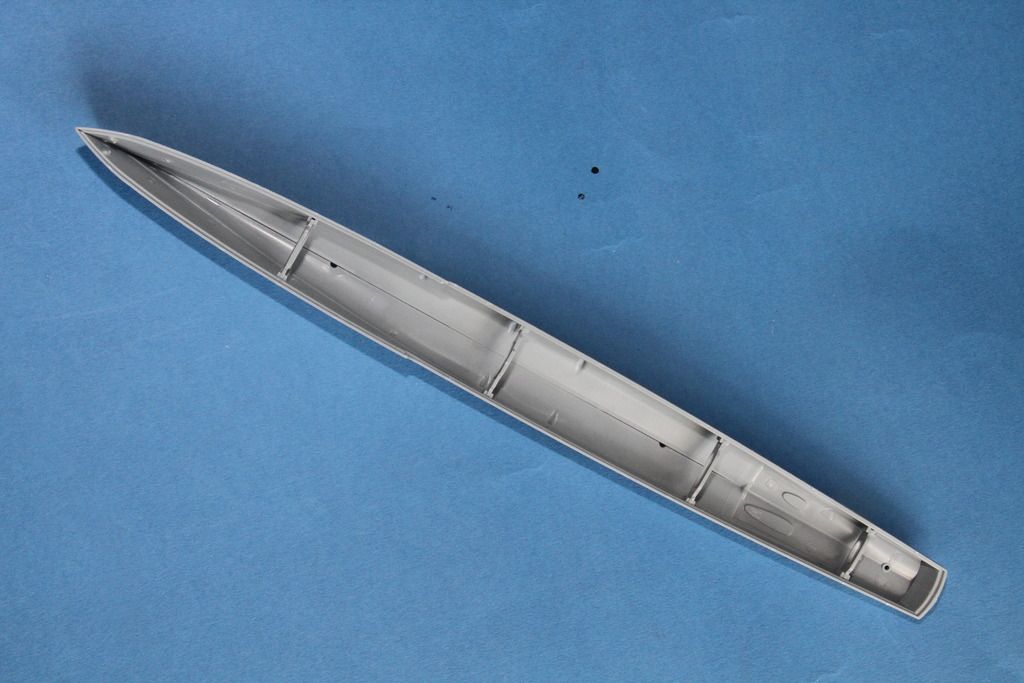

Having decided that I am going "overlook" the slight difference in beam, I thought the easy way to handle the shortening of the hull was to make a rigid structure and cut that up, rather risk deforming floppy bits.

The start, one interesting design feature that worked well, was that you can slot the stiffening in after going the halves together.

Stage one.

Stage two, the lower stern section in place.

stage 3 all the bulkheads in.

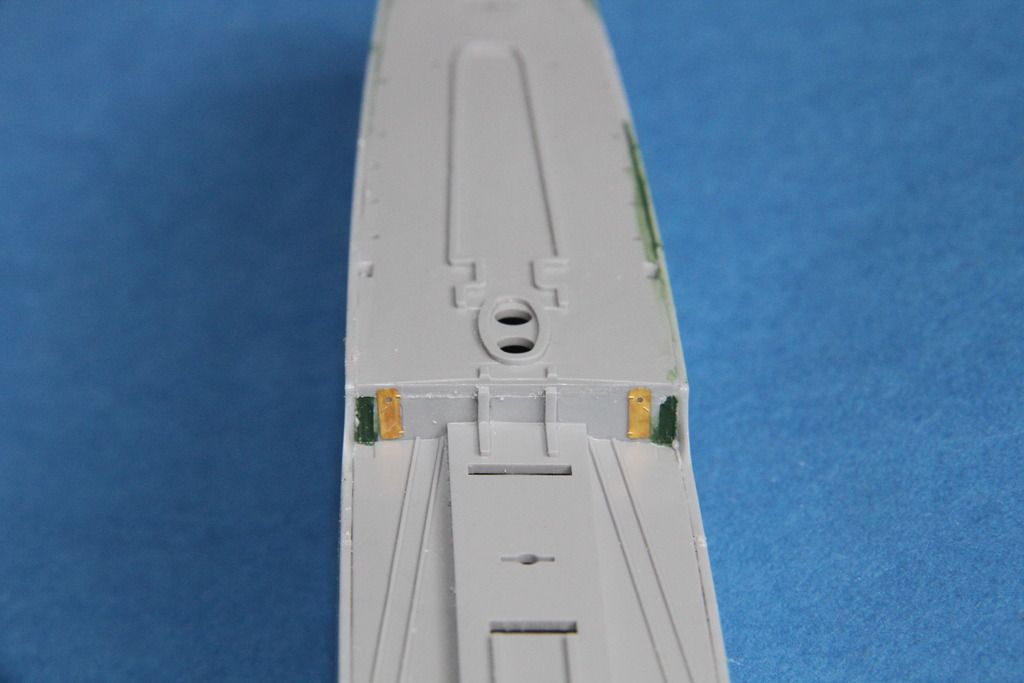

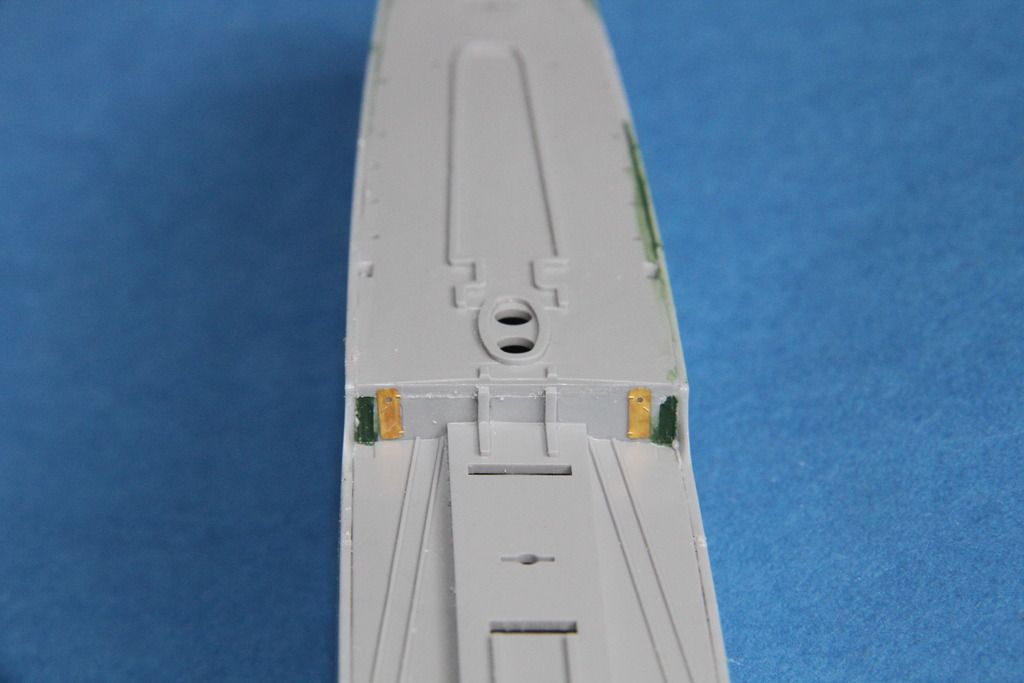

The bulkhead below the break in the fo'c's'le out of the box.

In place, with the decks, scrap etch doors fitted and the ladders removed and filled.

same thing from above.

Asymetric prop shafts, don't know if this is right, but I am going to live with it.

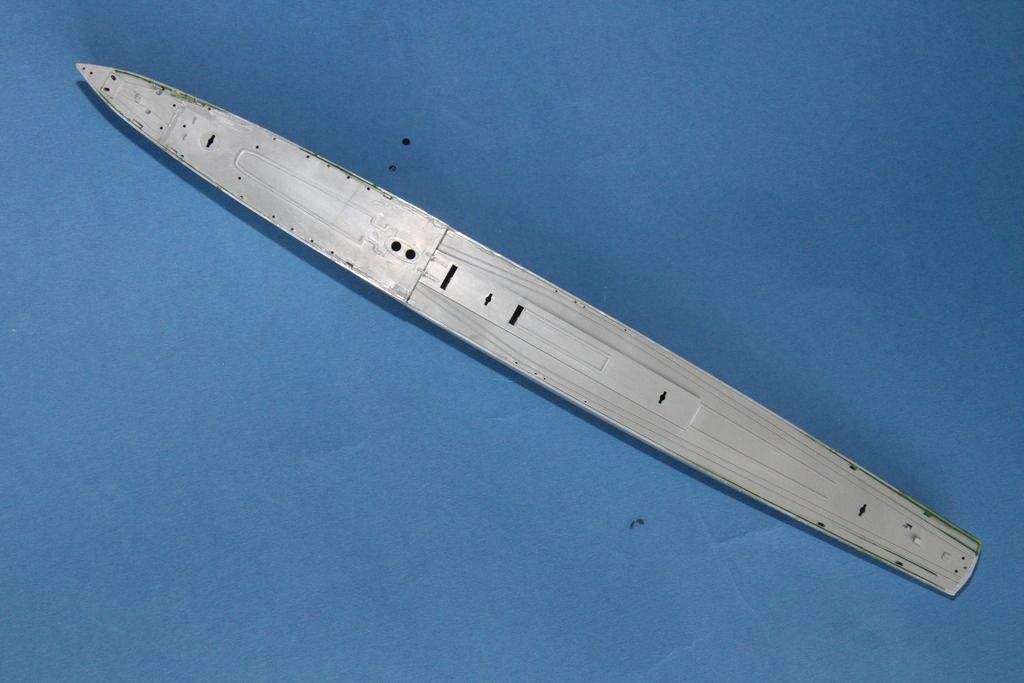

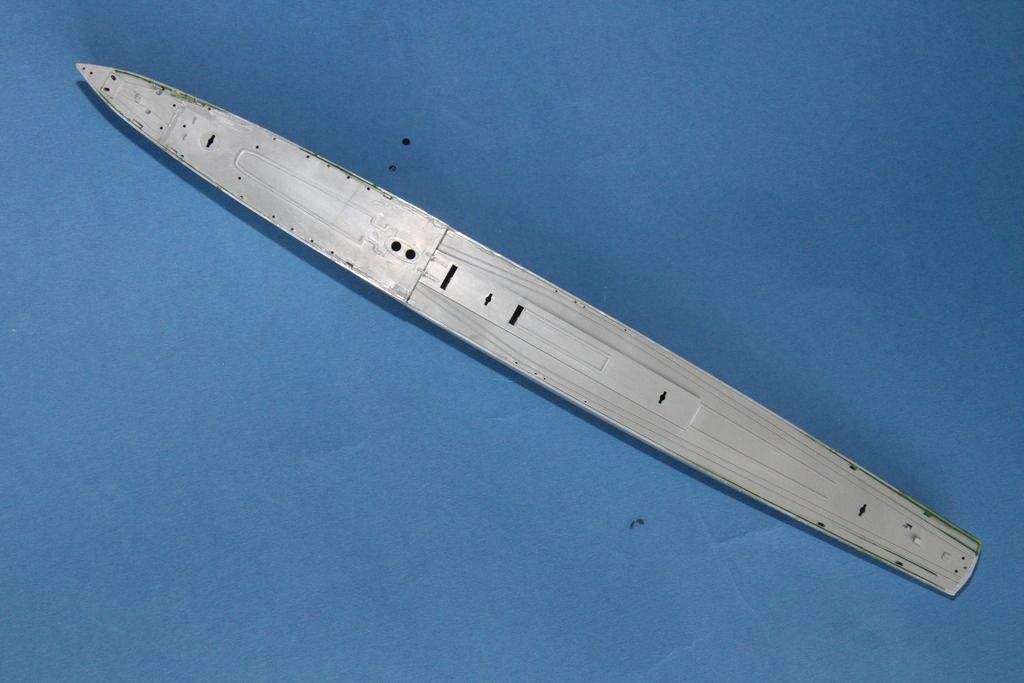

Coat of primer, shows the current issues, and easy for marking the cuts.

next the scary bit.

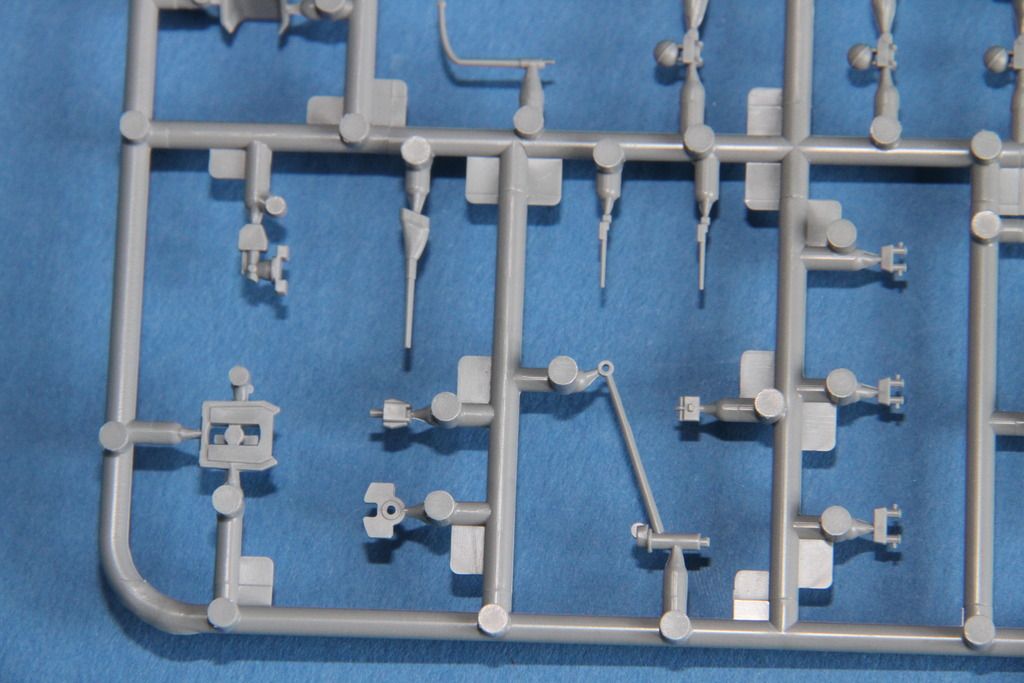

Razor saw at the ready.

more soon.

Si