Tim,

just as Mark and Russ say, the bridge with all the fantastic detail you put on it simply looks awesome!

Cheers

Jan

You are viewing the archived version of the site.

Go to modelshipwrights.com for the current dynamic site!

Go to modelshipwrights.com for the current dynamic site!

Hosted by Jim Starkweather

1/200 Nichimo Hatsuzuki build

Posted: Friday, August 07, 2020 - 08:49 AM UTC

Posted: Friday, August 07, 2020 - 01:55 PM UTC

That bridge looks great! I love how busy it looks!

This for me is the hardest thing about warship modelling: Finding the references to fill up all of the spaces the kit maker leaves empty.

Bravo, Tim!

This for me is the hardest thing about warship modelling: Finding the references to fill up all of the spaces the kit maker leaves empty.

Bravo, Tim!

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Sunday, August 09, 2020 - 04:47 AM UTC

Thanks guys!

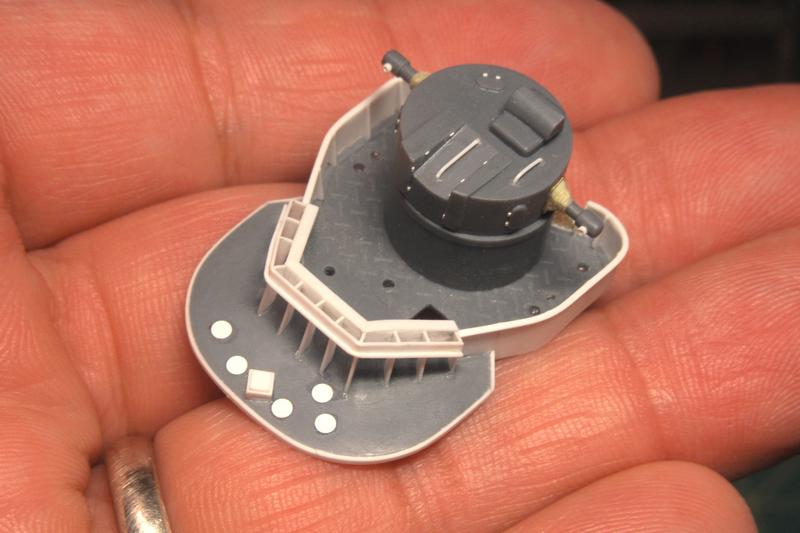

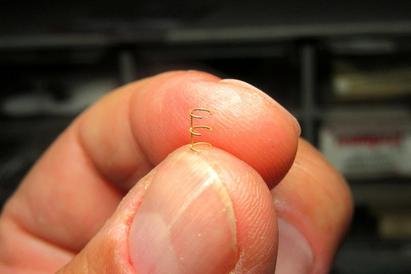

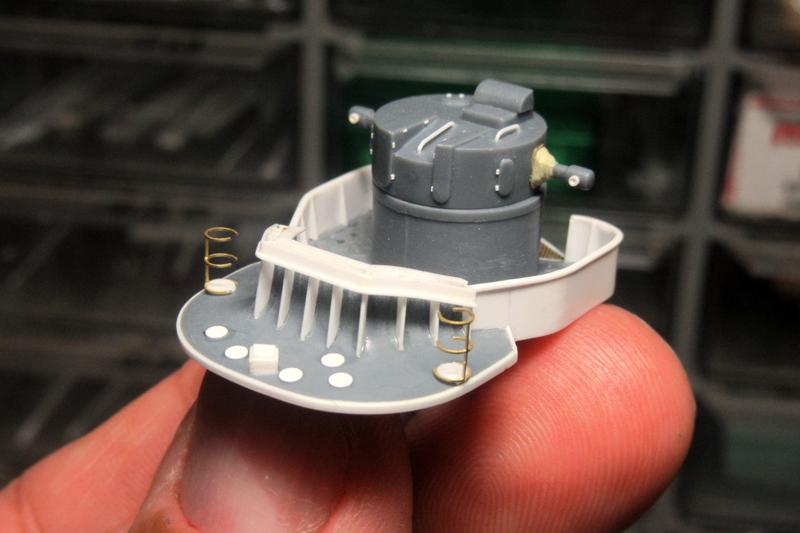

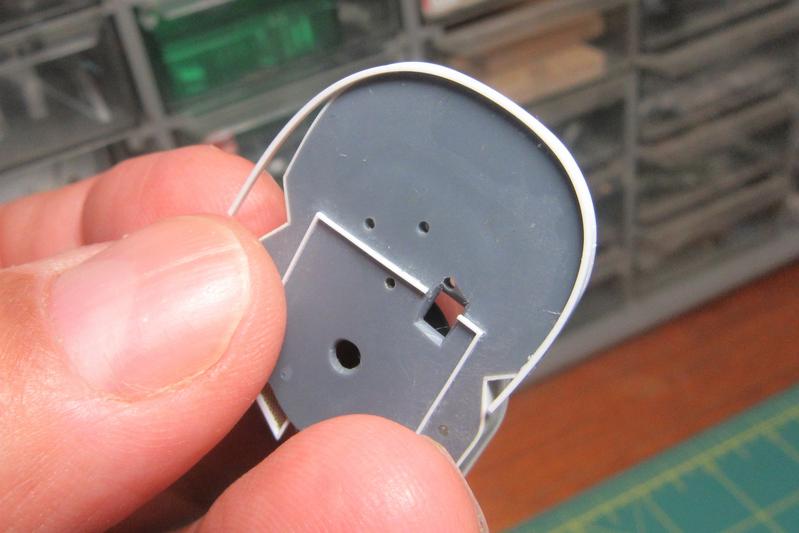

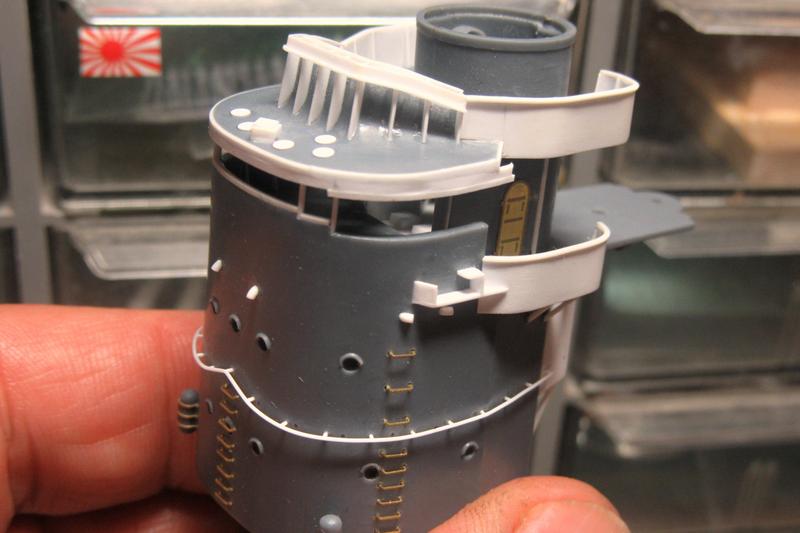

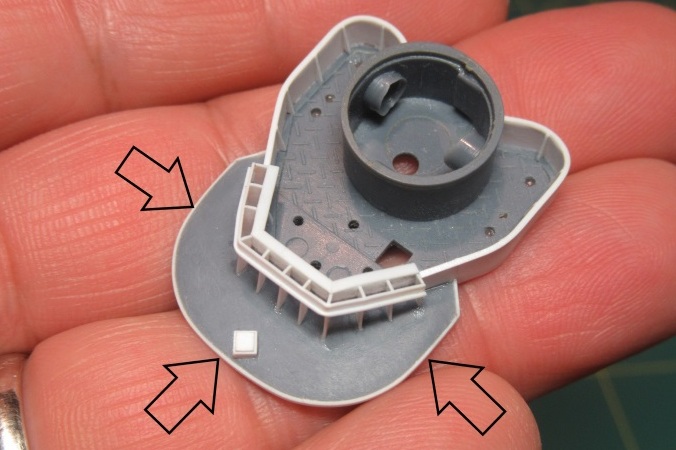

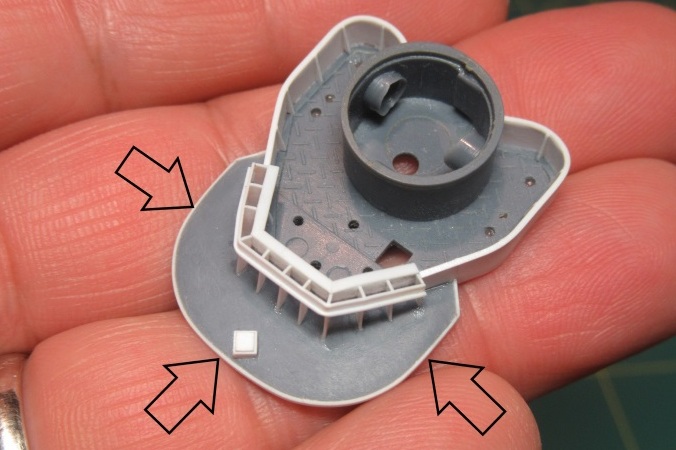

Gary, I know what you mean about finding references to answer all the questions that come up. For example, although I could find no photographs, there apparently were a group of small discs on top of the pilothouse roof. They would have been too small for a man to get through, but the 1/100 scale model in IJN Akizuki-class Destroyers Pacific War Series book shows them to open like little hatches. I suppose they must have been for ventilation.

Whatever their purpose, I added five .063 inch discs (punched from paper-thin .005 inch plastic) to the navigation bridge roof.

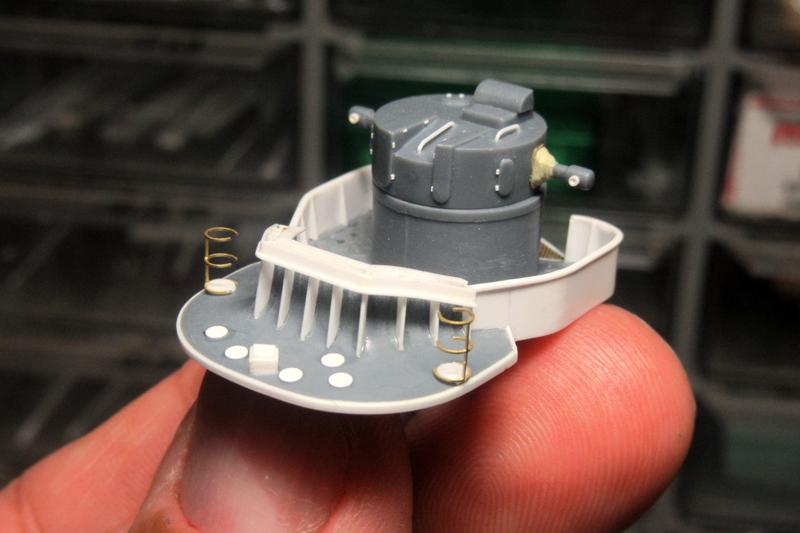

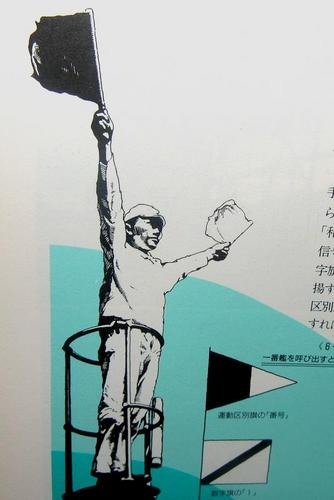

There were also a pair of signalman’s platforms on the navigation bridge roof edges.

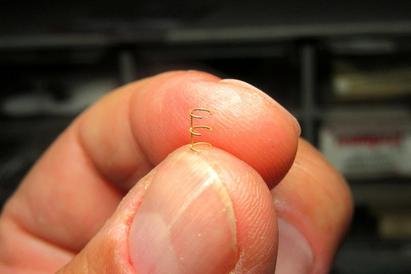

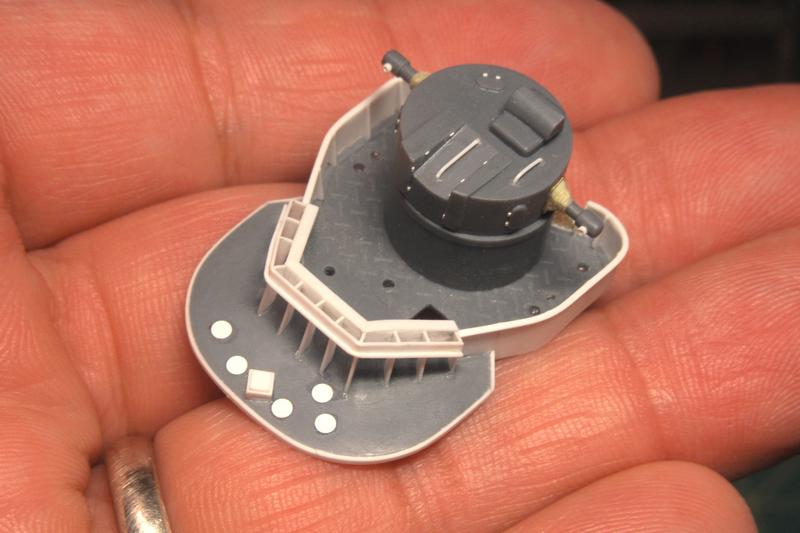

These were made with small sections of brass handrail from Gold Medal Models 1/200 IJN 2-Bar Railing set and .089 inch discs cut from .010 inch plastic sheet.

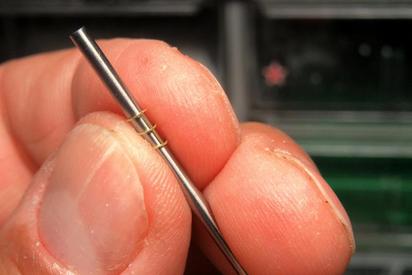

Rolled around the tap used to make the disc, the rails were formed into neat cylinder shapes. Then I wrapped them around the next smaller tap to help the brass to grip the disc bases when fitted over them.

Perched on the extreme edges of the pilothouse roof, these little cages provided a modicum of safety for the signalmen in these precarious positions high above the main deck.

Gary, I know what you mean about finding references to answer all the questions that come up. For example, although I could find no photographs, there apparently were a group of small discs on top of the pilothouse roof. They would have been too small for a man to get through, but the 1/100 scale model in IJN Akizuki-class Destroyers Pacific War Series book shows them to open like little hatches. I suppose they must have been for ventilation.

Whatever their purpose, I added five .063 inch discs (punched from paper-thin .005 inch plastic) to the navigation bridge roof.

There were also a pair of signalman’s platforms on the navigation bridge roof edges.

These were made with small sections of brass handrail from Gold Medal Models 1/200 IJN 2-Bar Railing set and .089 inch discs cut from .010 inch plastic sheet.

Rolled around the tap used to make the disc, the rails were formed into neat cylinder shapes. Then I wrapped them around the next smaller tap to help the brass to grip the disc bases when fitted over them.

Perched on the extreme edges of the pilothouse roof, these little cages provided a modicum of safety for the signalmen in these precarious positions high above the main deck.

RedDuster

Joined: March 01, 2010

KitMaker: 7,078 posts

Model Shipwrights: 6,649 posts

Posted: Sunday, August 09, 2020 - 06:30 AM UTC

Hi Tim,

The bridge roof is nice and busy. The signalman's positions look good, will you be adding the two end verticals and the top bar in the opening?

Cheers

Si

The bridge roof is nice and busy. The signalman's positions look good, will you be adding the two end verticals and the top bar in the opening?

Cheers

Si

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Sunday, August 09, 2020 - 06:52 AM UTC

Quoted Text

Hi Tim,

The bridge roof is nice and busy. The signalman's positions look good, will you be adding the two end verticals and the top bar in the opening?

Cheers

Si

Definitely, especially the openable horizontal retainer on the top bar - we don't want our brave signalmen falling off now, do we?

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Thursday, August 13, 2020 - 12:19 PM UTC

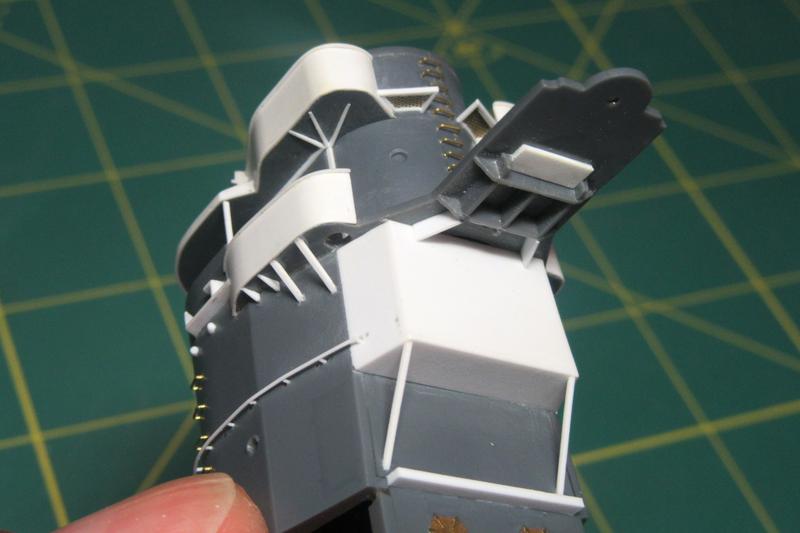

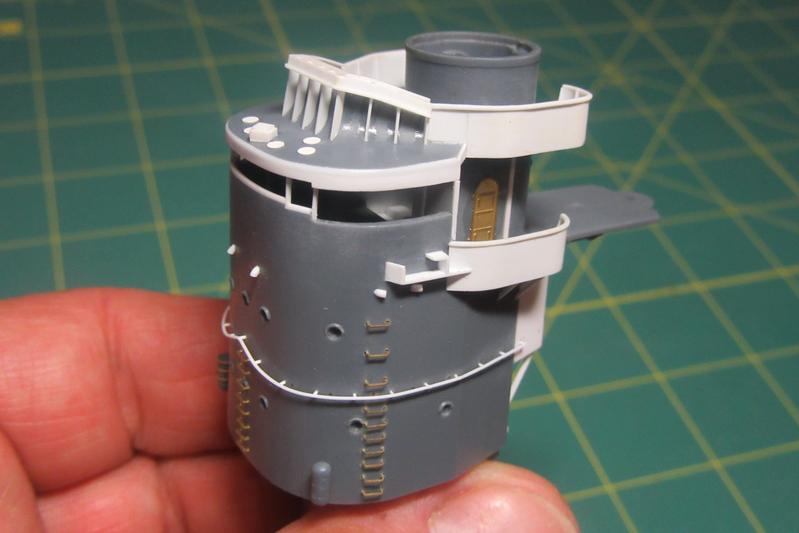

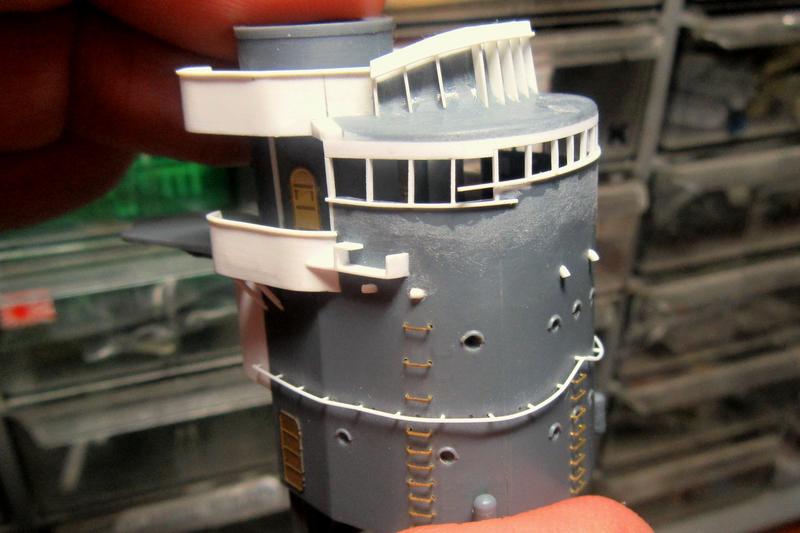

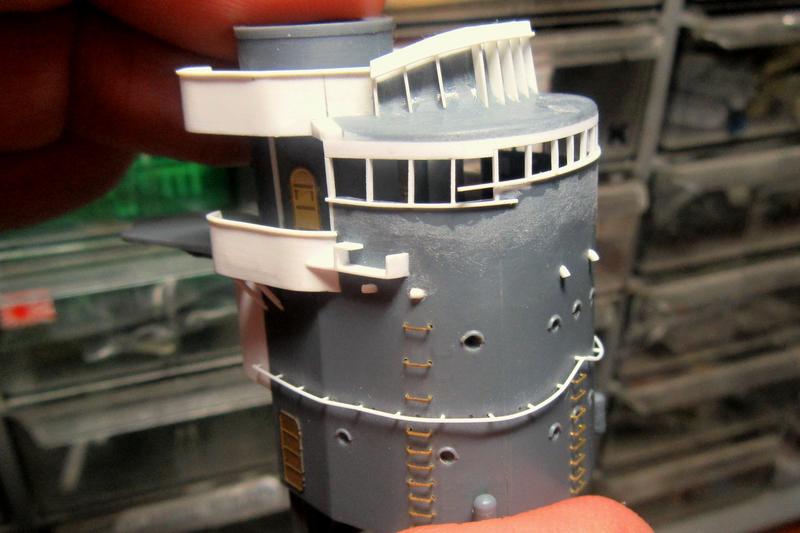

Having already added braces under the bridge wings, it seemed right to add a few under the upper air defense station too.

Next up: the bridge windows

RedDuster

Joined: March 01, 2010

KitMaker: 7,078 posts

Model Shipwrights: 6,649 posts

Posted: Friday, August 14, 2020 - 06:23 AM UTC

Glad to see your taking the health and safety of your crew into account.

The structure all around the bridge looks very good indeed, nice and busy.

Cheers

Si

The structure all around the bridge looks very good indeed, nice and busy.

Cheers

Si

bwiber

Joined: August 03, 2008

KitMaker: 436 posts

Model Shipwrights: 31 posts

Posted: Saturday, August 15, 2020 - 08:59 AM UTC

Quoted Text

Though not as easy to work as styrene plastic, the new 3D printed parts go a long way to update Nichimo’s basic injection molded shapes.

Of course, all that white styrene does nothing towards updating the basic molded shapes... right?

Actually, you probably could have broken this down into several "kits". I mean you are adding enough detail to the bridge to make it almost a stand alone kit by itself. However, have to admit I am enjoying the heck out of this one.

Love the signal positions, not that I would be in a hurry to hop into one of them. Not that I would fit anymore...

Bob

Kevlar06

Joined: March 15, 2009

KitMaker: 3,670 posts

Model Shipwrights: 173 posts

Posted: Saturday, August 15, 2020 - 10:50 AM UTC

What I want to know is how often Tim has to visit the optometrist. I’d go cross eyed putting all that detail into a ship kit at the rate he builds this stuff. He must also have tweezers for fingers, cause there’s no way I’d be able to handle detail like the PE signal posts without crushing them in my fat fingers. Bravo Tim!

VR, Russ

VR, Russ

Posted: Sunday, August 16, 2020 - 01:07 PM UTC

Wow Tim! This will look amazing when it's all assembled

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Tuesday, August 18, 2020 - 03:07 PM UTC

Quoted Text

What I want to know is how often Tim has to visit the optometrist. I’d go cross eyed putting all that detail into a ship kit at the rate he builds this stuff. He must also have tweezers for fingers, cause there’s no way I’d be able to handle detail like the PE signal posts without crushing them in my fat fingers. Bravo Tim!

VR, Russ

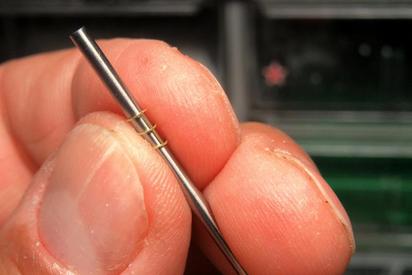

You will laugh, but my high tech optical boost system consists of a pair of Dollar Store reading glasses with lenses from a second pair taped over them to double the magnification.

Really, these are what I use!

Posted: Tuesday, August 18, 2020 - 07:01 PM UTC

Love the supports. I wish they were modeled more often.

Ripster

Joined: June 01, 2005

KitMaker: 970 posts

Model Shipwrights: 446 posts

Posted: Tuesday, August 18, 2020 - 07:24 PM UTC

Quoted Text

You will laugh, but my high tech optical boost system consists of a pair of Dollar Store reading glasses with lenses from a second pair taped over them to double the magnification.

Really, these are what I use!

Nice, restrained colour scheme there!

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Thursday, August 20, 2020 - 01:28 AM UTC

Quoted Text

Quoted Text

You will laugh, but my high tech optical boost system consists of a pair of Dollar Store reading glasses with lenses from a second pair taped over them to double the magnification.

Really, these are what I use!

Nice, restrained colour scheme there!

I know - my 16 year old daughter just shakes her head...

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Thursday, August 20, 2020 - 02:00 AM UTC

Quoted Text

Actually, you probably could have broken this down into several "kits". I mean you are adding enough detail to the bridge to make it almost a stand alone kit by itself. However, have to admit I am enjoying the heck out of this one.

Bob

Thanks Bob. You are right, in this larger scale it seems every assembly seems to turn into a mini project unto itself!

Speaking of which... with the basics of the bridge structure in place, I made a start on the windows.

I initially thought this would be a simple matter of inserting window frames from .010”X.020” strip... but when test fitted they just didn’t look quite right. Comparing it with photos, I realized the windows were too tall and too uniform – especially at the top.

Part of the solution was to add a shim to the underside of the roof...

Shims were also added to the lower parts of the front windows and an additional shim added to the roof of each side.

These measures did reduce the various windows to the correct heights, but now that I've smoothed and faired everything in it has become evident that my changes also created an inaccurate overhang, giving the bridge “face” a sort of heavy brow ridge. Yuck.

Posted: Thursday, August 20, 2020 - 02:21 AM UTC

Tim,

Your modification for the windows sure reduced the view looking out from the bridge. Was that the design of the ship? Kinda reminds me of the low windows on a Chrysler 300 sedan.

Mark

Your modification for the windows sure reduced the view looking out from the bridge. Was that the design of the ship? Kinda reminds me of the low windows on a Chrysler 300 sedan.

Mark

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Thursday, August 20, 2020 - 05:10 AM UTC

Quoted Text

Tim,

Your modification for the windows sure reduced the view looking out from the bridge. Was that the design of the ship? Kinda reminds me of the low windows on a Chrysler 300 sedan.

Mark

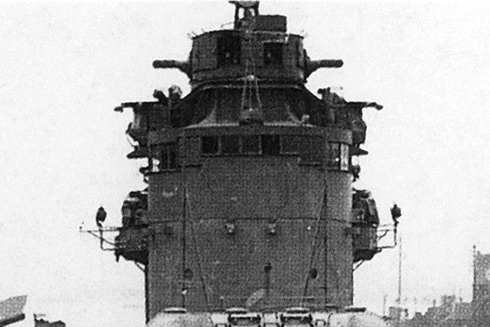

Mark, yes, the smaller windows forward were how the ship was designed. Take a look at this pic of near-sister Harutzuki:

You can see that the windows are largest at the sides and they get smaller going towards the bow.

Unfortunately, you can also see that my changes on the model made an inaccurate overhang... I'll have to figure out how to fix that!

Posted: Thursday, August 20, 2020 - 07:25 AM UTC

Wow Tim,

this is simply amazing! As was said by everyone before... Just brilliant how you look into every single detail! I hope you'll find a solution to the overhang - your bridge looks just marvelous!

Cheers

Jan

this is simply amazing! As was said by everyone before... Just brilliant how you look into every single detail! I hope you'll find a solution to the overhang - your bridge looks just marvelous!

Cheers

Jan

Posted: Thursday, August 20, 2020 - 08:38 PM UTC

Quoted Text

These measures did reduce the various windows to the correct heights, but now that I've smoothed and faired everything in it has become evident that my changes also created an inaccurate overhang, giving the bridge “face” a sort of heavy brow ridge. Yuck.

Ooo, tough dilemma, Tim... Short of pulling off the plastic sheeting and recessing it back in, I can't think of anything...

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Friday, August 21, 2020 - 02:09 AM UTC

Quoted Text

Wow Tim,

this is simply amazing! As was said by everyone before... Just brilliant how you look into every single detail! I hope you'll find a solution to the overhang - your bridge looks just marvelous!

Cheers

Jan

Quoted Text

Ooo, tough dilemma, Tim... Short of pulling off the plastic sheeting and recessing it back in, I can't think of anything...

Thanks Jan & Russ. Even though the job on the bridge window frames was pretty much done and mostly correct, I just couldn’t think of a clever solution to that ugly overhang – so last night I cut away all the shims on the roof ...

My workday begins soon this morning, but this weekend (after I regain my composure!) I’ll hit it again.

Kevlar06

Joined: March 15, 2009

KitMaker: 3,670 posts

Model Shipwrights: 173 posts

Posted: Friday, August 21, 2020 - 05:44 AM UTC

Quoted Text

Quoted TextWhat I want to know is how often Tim has to visit the optometrist. I’d go cross eyed putting all that detail into a ship kit at the rate he builds this stuff. He must also have tweezers for fingers, cause there’s no way I’d be able to handle detail like the PE signal posts without crushing them in my fat fingers. Bravo Tim!

VR, Russ

You will laugh, but my high tech optical boost system consists of a pair of Dollar Store reading glasses with lenses from a second pair taped over them to double the magnification.

Really, these are what I use!

Tim,

Looking good! Necessity is the mother of invention they say. I think they’re great! Do you play Elton John music while wearing them? I used to have an optivisor, but I also wear trifocals, and found the combination a real pain to manage. In fact, I’d take my glasses off to work small details with (I’m nearsighted), but lately, as I’ve gotten even older, I’ve found I need something else, so like you, I have the same kind of set up. I bought a cheap pair of +3 reading magnifiers, and a set of +2 and +3 “clip ons” from Micro-Mark that I just clip over the cheapo magnifiers, that way I can flip them up when I need to change the diopter. But I have to admit, they’re not as stylish as yours

As for the windows, I think they’re fine as is, but, knowing you are a detail and fashion perfectionist now (by seeing your glasses), I’m sure you’ve thought about it already, but you could trim it all off, and place the styrene strip on the underside of the overhang, rather than the edge. That would bring the trim down, with no “overbite”. But if you look at the windows in the photo, I think they’re all the same size— it’s just the ones facing the bow are placed higher than the ones to port or starboard, so you’d only need to have the “trim” on the overhang on the port and starboard side, with no trim facing the bow, and then run a strip “under” the bow windows to raise them. My two cents worth. This is going to really be something when finished.

VR, Russ

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Friday, August 21, 2020 - 09:02 AM UTC

Quoted Text

Tim,

Looking good! Necessity is the mother of invention they say. I think they’re great! Do you play Elton John music while wearing them? I used to have an optivisor, but I also wear trifocals, and found the combination a real pain to manage. In fact, I’d take my glasses off to work small details with (I’m nearsighted), but lately, as I’ve gotten even older, I’ve found I need something else, so like you, I have the same kind of set up. I bought a cheap pair of +3 reading magnifiers, and a set of +2 and +3 “clip ons” from Micro-Mark that I just clip over the cheapo magnifiers, that way I can flip them up when I need to change the diopter. But I have to admit, they’re not as stylish as yours

LOL! I actually have another pair of Dollar Store readers with rhinestones that my wife refuses to let me wear...

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Friday, August 21, 2020 - 09:06 AM UTC

Quoted Text

As for the windows... you could trim it all off, and place the styrene strip on the underside of the overhang, rather than the edge. That would bring the trim down, with no “overbite”. But if you look at the windows in the photo, I think they’re all the same size— it’s just the ones facing the bow are placed higher than the ones to port or starboard, so you’d only need to have the “trim” on the overhang on the port and starboard side, with no trim facing the bow, and then run a strip “under” the bow windows to raise them. My two cents worth. This is going to really be something when finished.

VR, Russ

Thanks Russ, I think you have the right idea to attach the styrene strip on the underside of the overhang rather than on the edge. Oddly, the forward windows really were a bit smaller. Check out this view of Harutzuki:

Anyway, I’ve already done the tear-down... I just need get up the gumption to build it all back up again.

Kevlar06

Joined: March 15, 2009

KitMaker: 3,670 posts

Model Shipwrights: 173 posts

Posted: Friday, August 21, 2020 - 10:05 AM UTC

Tim,

Yes, that bow shot of the bridge does tell the story better, those windows are smaller and look square in comparison to the port and starboard windows, which look rectangular. But I have no doubt you'll figure it out. Can't wait till you show us how you did it.

I think you you should save the rhinestone glasses for special occasions, like when you place the last bit of detail onto the model! I have a celebratory ritual that I go through-- I have a special hat I put on to let my family know I've finished it. It's a baseball hat given to me by the Commander of the Japanese 6th Infantry Division in 1988, during a trip to Sendai Japan. It's significantly gaudy with lots of "scrambled eggs" and braid. I call it my "Triumphant Admiral of the Horse Marines Cap", and wear it when I place the last finishing detail. That way my family knows its safe to approach, and the swearing will stop.

VR Russ

Yes, that bow shot of the bridge does tell the story better, those windows are smaller and look square in comparison to the port and starboard windows, which look rectangular. But I have no doubt you'll figure it out. Can't wait till you show us how you did it.

I think you you should save the rhinestone glasses for special occasions, like when you place the last bit of detail onto the model! I have a celebratory ritual that I go through-- I have a special hat I put on to let my family know I've finished it. It's a baseball hat given to me by the Commander of the Japanese 6th Infantry Division in 1988, during a trip to Sendai Japan. It's significantly gaudy with lots of "scrambled eggs" and braid. I call it my "Triumphant Admiral of the Horse Marines Cap", and wear it when I place the last finishing detail. That way my family knows its safe to approach, and the swearing will stop.

VR Russ

TimReynaga

Joined: May 03, 2006

KitMaker: 2,500 posts

Model Shipwrights: 1,830 posts

Posted: Sunday, August 23, 2020 - 03:33 PM UTC

Russ, I love your crazy completion ceremonial cap - brilliant! I'll have to institute something similar myself so - as you say - my family will know that the swearing has stopped and it is safe to approach!

As for Hatsuzuki, it will be a while until that day, but I am making progress…

Taking another look at the roof after removing the shims, I was able to identify the mistake I had made:

I'd previously added a thin strip around the perimeter of the roof to sharpen the outline, but in doing so I had also disrupted the geometry of the structure. This became painfully evident when I started to add the windows!

After trimming the roof edge to even it up again with the lower part of the structure, I fitted new shims. Now things line up perfectly. This time I also included a small ridge fitted to the outer edge of the roof shim from .010”X.010” strip.

This new shim would stand a modest .010” (two scale inches) proud of the structure to frame the windows. I also added similar pieces to the lower frames.

Cleaned up and test fitted with the vertical frames in place, the assembly captures the look of the Hatsuzuki’s windows much more successfully than my first attempt!

As for Hatsuzuki, it will be a while until that day, but I am making progress…

Taking another look at the roof after removing the shims, I was able to identify the mistake I had made:

I'd previously added a thin strip around the perimeter of the roof to sharpen the outline, but in doing so I had also disrupted the geometry of the structure. This became painfully evident when I started to add the windows!

After trimming the roof edge to even it up again with the lower part of the structure, I fitted new shims. Now things line up perfectly. This time I also included a small ridge fitted to the outer edge of the roof shim from .010”X.010” strip.

This new shim would stand a modest .010” (two scale inches) proud of the structure to frame the windows. I also added similar pieces to the lower frames.

Cleaned up and test fitted with the vertical frames in place, the assembly captures the look of the Hatsuzuki’s windows much more successfully than my first attempt!

|