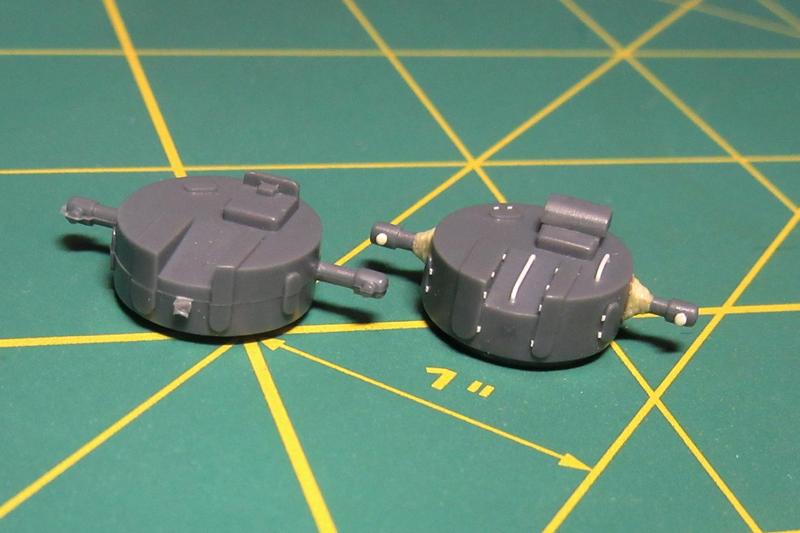

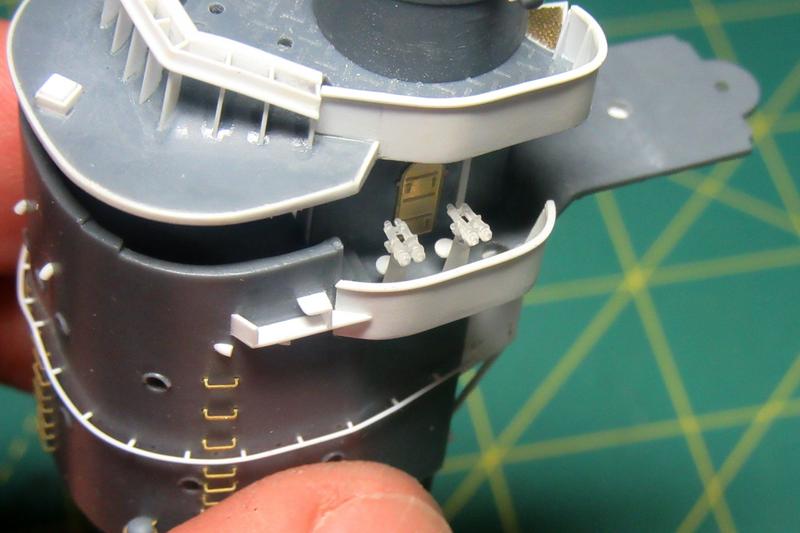

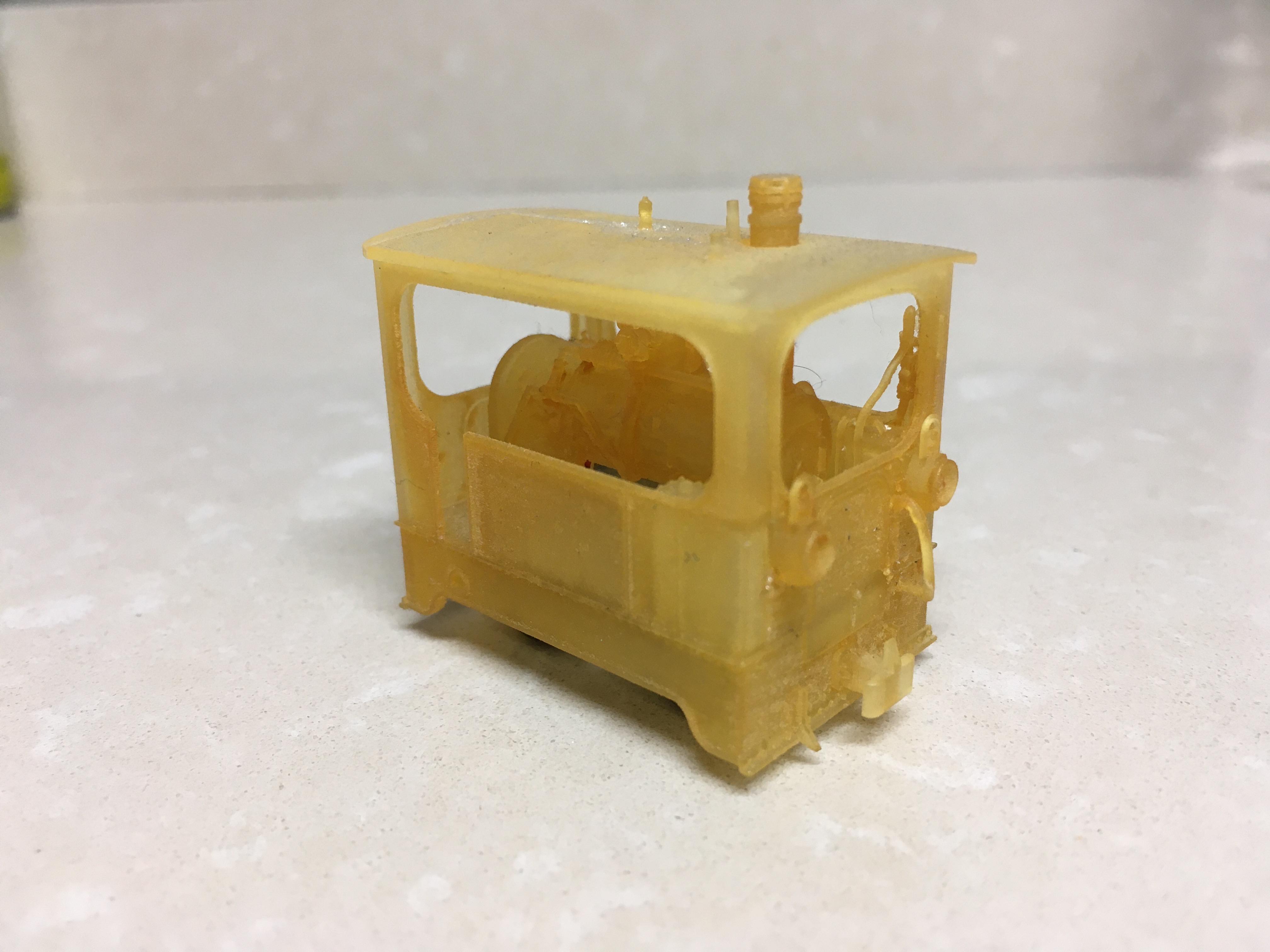

This is, I think Noº I bought from Sven. He worked more than 2 years on the initial Tram. By that time in 2012 it was quite unique having such a little tram with outstanding detail. Provided with a micro motor and later a decoder for sound and realistic moving on the rail track. All detail on the tank is there. Inside of the 'Kasten Loc' 100% ok.

It came in a little 'soap box'

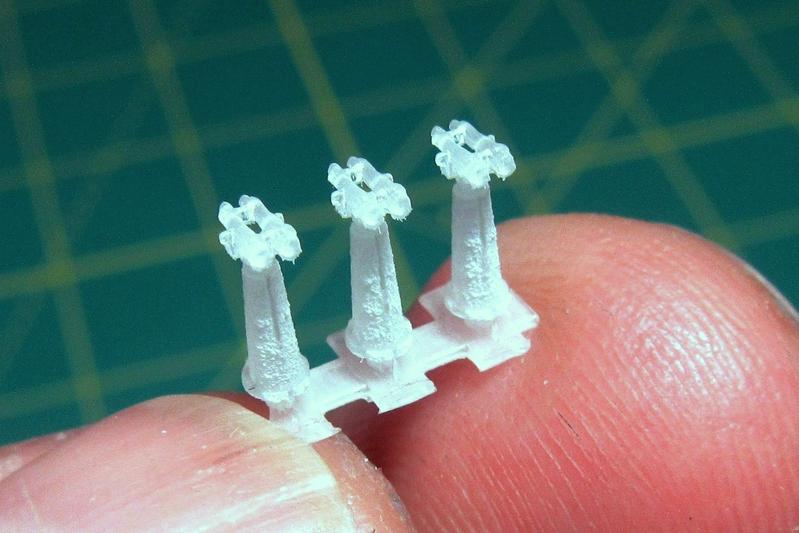

He managed to make the roof a separate part

All is there, the brake, fittings on the kettle, the bell and flute on the roof.

He wrote a review for this piece of art and one day he asked me to edit in comparison with my experiences on the painting.

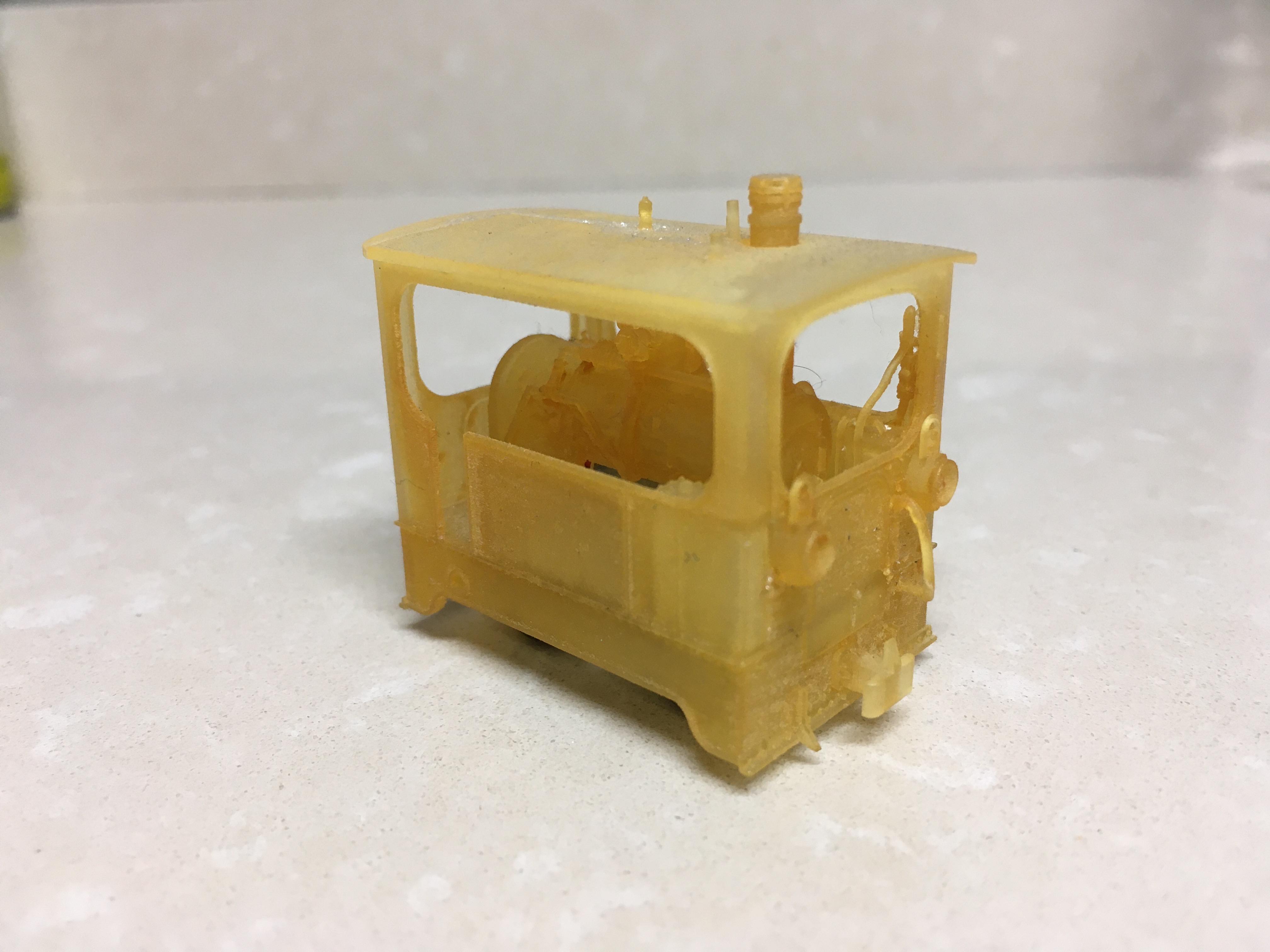

Well this little dinosaur never got one, get one. Its my time marking modeling was to change a lot.

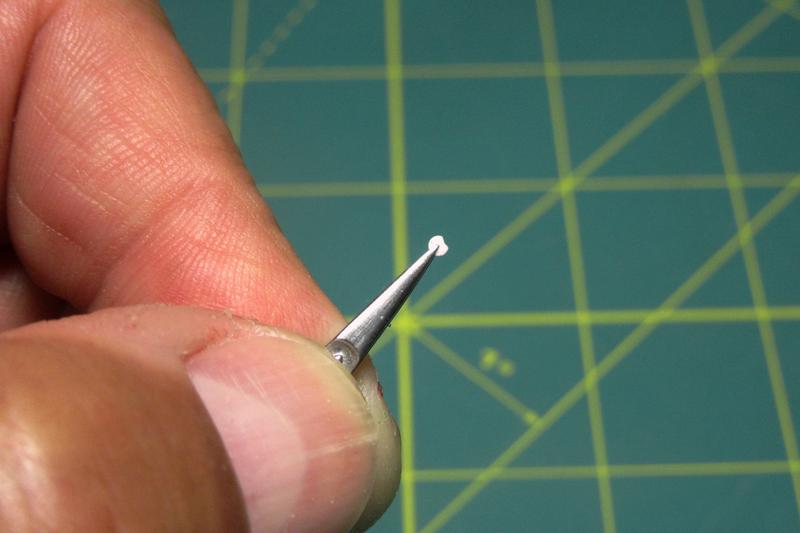

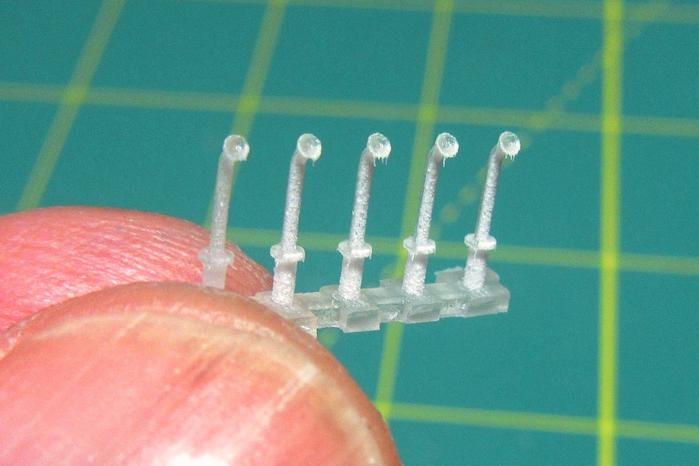

You want to see how little this one is. Well this big.

It's very tempting to spray some paint on it, but I will not as I stated above.

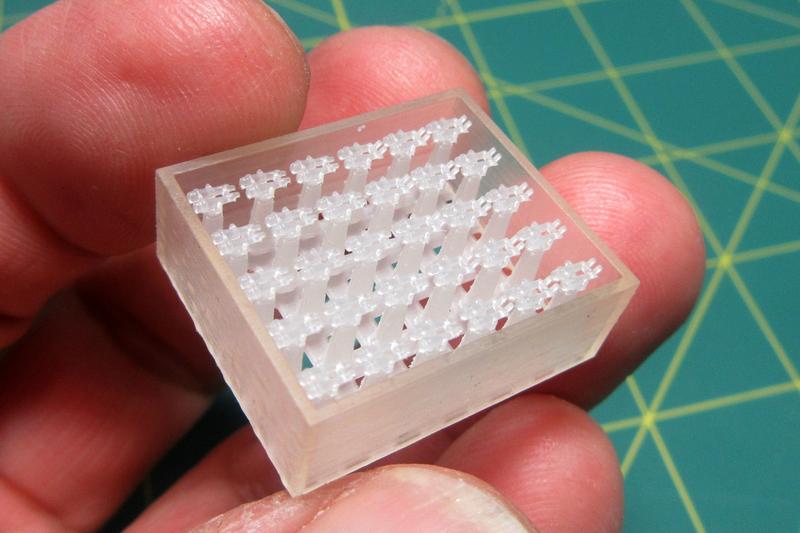

For that time, some 8 years ago, it still has the quality, somewhat yellowing now, but undamaged.

Yes and this has nothing to with your ship, but I doubt quality of 3D printing over the years, become a big money maker and there are a lot of people offering. This one cost me about 85 Euros, including micro motor installed.

I actually did build 3 of these little Trams and sold them to customers I had, commission as they say.

Just my 2 cents on 3D printing, I love it.

maybe

but I had to.