So I've been working on the bow parts (still, again, forever). After stretching the big curved parts to get them to fit, especially on the port side, I had to do some fixing for part 252, "trimming for curve" (well, it might be part 253, whichever is for the port side). There was a fairly big gap between the curved part and the trimming for curve, so here's some pictures of the process of adding some plastic to make things sort of look presentable:

This is the first go-round with adding some plastic:

And here's a couple more pictures, showing some more additional plastic, as well as fitting it to the curved part:

And here's a final fit:

So here's a pic of the starboard bow, with trim piece and the curved part that will hold the cathead:

Here's the port side. If you compare the previous picture with this one, you can see how much extra plastic was added to the trim work, to make it reach back to the curved piece:

This picture shows how the curved piece that holds the cathead (the blue & yellow piece, curving in from the right, at the center of the photo) does not completely connect to the timber from the big lattice part. In a perfect world, these 2 parts would have connected:

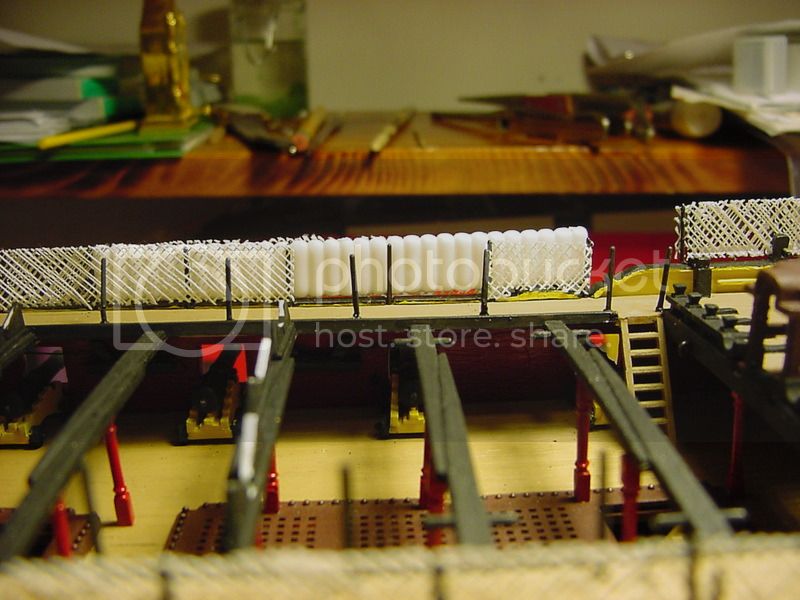

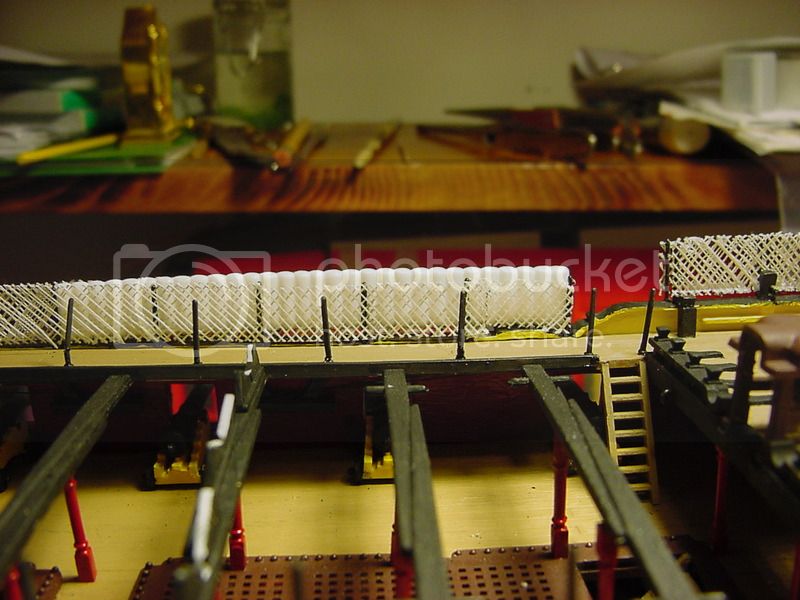

In the instructions, it says to put in place parts 178 & 179, which are cannonball lockers (for the swivel guns that are forward). However, the instructions are sort of vague (thanks, Heller!) about how these lockers are supposed to go around the post that was already cemented a few steps back. So here's the space where the cannonball lockers go, and how the parts initially sat:

This first photo isn't exactly from 90 degrees above, so it gives a false sense of the problem:

Here's one idea I had about emplacing these lockers, but it would just look dumb butting up against the post:

So here's the second idea: put the locker on top of the ledge from the bulkhead:

This picture gives you a better idea how the locker lays up on the bulkhead:

So what I did, I marked about where the lockers fit around those posts, got the Dremel tool out and machined away some of the plastic, and got quite a good fit. I had to do a little extra sanding on the port locker, on the side that faces the bulkhead, but everything fit quite well (esp. the starboard side - it was tight enough just to press-fit it into place! But I glued it anyways). And this is the finished process:

And lastly, a picture of the bow, with the catheads installed (I noticed earlier that I still need to add another part to the cathead!):

So the next couple of steps are putting in those pieces on the cathead, gluing up the bowsprit, paint & install the shield & crown, and then start making-up the initial rigging for the bowsprit. That should keep me occupied until about October (of 2017!!

)

)Thanks for watching!