You are viewing the archived version of the site.

Go to modelshipwrights.com for the current dynamic site!

Go to modelshipwrights.com for the current dynamic site!

1⁄350USS Lexington (CV2) 1927-1942

23

Comments

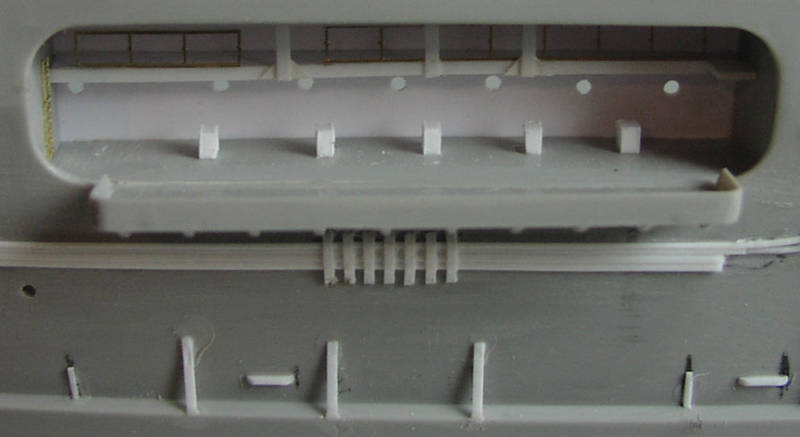

Stage 2: boat pockets

Kit parts: 5

Scratch parts: 26

PE parts: 15

Time: 8 hours

Overall impression: Where moulded-on catwalks are provided against the inside bulkheads these are positioned too low down and are also too narrow. There is also some irrelevant moulded-in rectangular window detail and complete absence of scuttles at two levels.

There are sufficient additional railings and ladders in the GMM photo-etch set, beyond what is required to replace the kit parts, to fit out the boat pockets. But only just. You need to retain the following from the set to replace the kit parts:

F12: 2

F13: 4

F14: 4

F15: 4

F16: 2

This will leave you with the following to fit out the boat pockets:

F14: 2

F15: 2

F16: 2

This will leave you two less than you need, but in practice, because the ladders need to be reduced in length, you will have off-cuts left over you can join together (tricky but possible) to complete the job.

All boat pockets were fitted out before installing them in the hull.

Below I have numbered these from forward to aft with the prefix P for port and S for starboard. Therefore P1 is the first boat pocket on the port side. There is of course only one boat pocket on the starboard side.

Above: Boat pocket P1 after installation in hull.

•P1: Removed inboard bulkhead and replaced with 0.2mm styrene sheet. Removed light AA platform locating tabs from deck. Drilled scuttles. Added walkway and 1mm wide vertical central stanchion, GMM 3-bar railing type 3 with central bar removed and GMM vertical ladder with hand rails removed and cut to length.

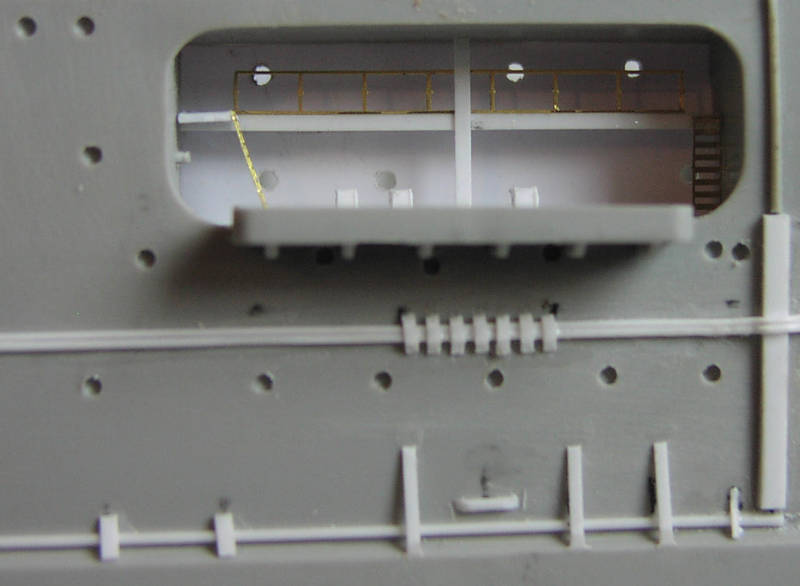

Above: Boat pocket P2 after installation in hull.

•P2: As P1 with addition of 1mm deep catwalk vertical edge. Moulded-in inclined ladder removed and moulded-in locating rib for catwalk on forward bulkhead to external inclined ladder to flight deck cut back beneath longitudinal catwalk. Residual boat crane mounting hubs removed from deck head. These crane arms actually pivoted horizontally about vertical mountings close to the deck head outboard edge.

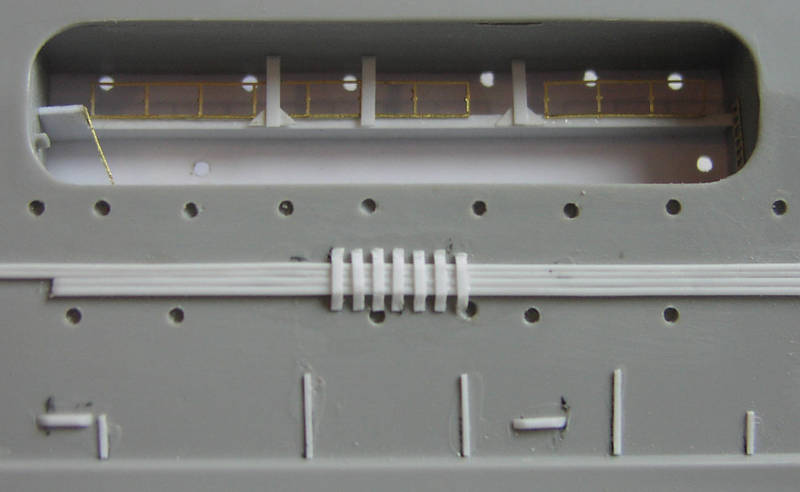

Above: Boat pocket P3 after installation in hull.

•P3: As P2 except aft vertical ladder up to catwalk is at right angles to it rather than 45 degrees. There is an additional, inclined, ladder running from a right-angled extension to the catwalk at the forward end down to the boat pocket deck.

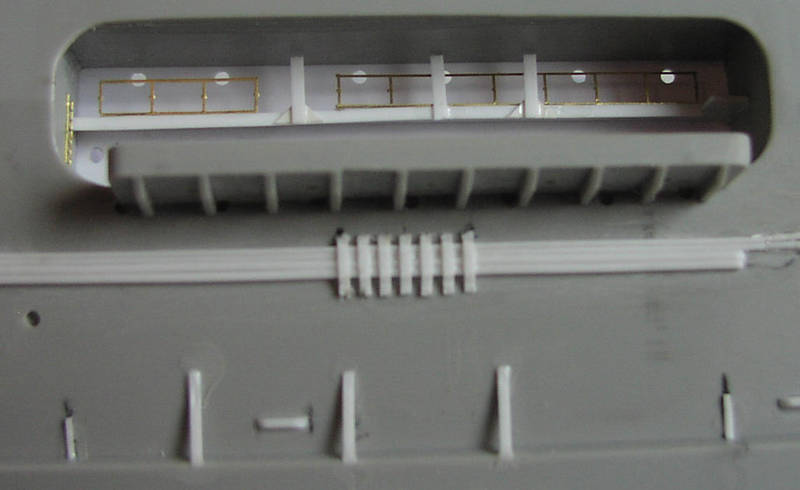

Above: Boat pocket P4 after installation in hull.

•P4: As P3 except two additional vertical stanchions between catwalk and deck head only.

Above: Boat pocket S5 after installation in hull.

•S5: Identical mirror-image of P4 except for additional scuttles at lower level.

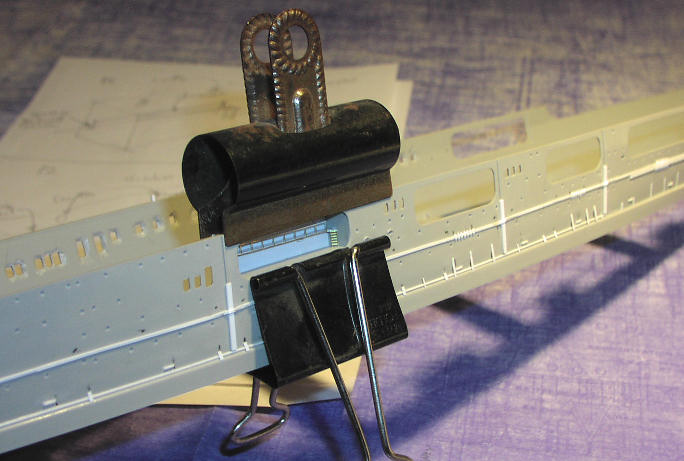

The outward bowing of the thin plastic above the boat pockets was easily corrected by clamping them to the boat pocket structures when these were cemented in place. The liquid poly adhesive was strong enough to hold the distortion in compression.

Above: Clamping boat pocket to hull.

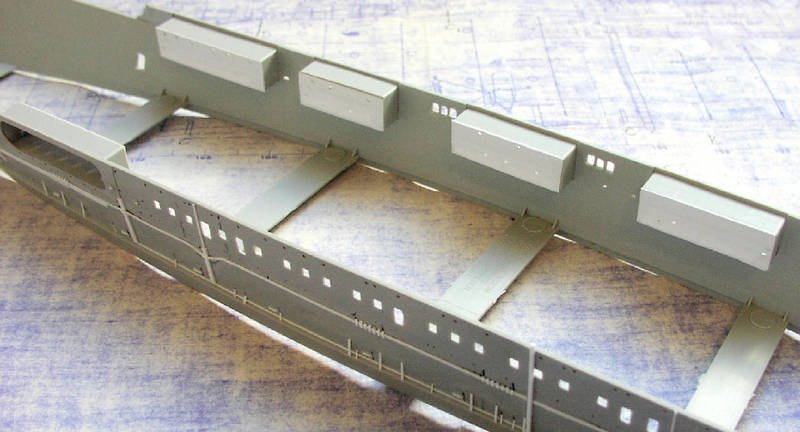

Above: Boat pockets installed.

Comments

Hi Joseph,

Yeah, it was a lot of research. I was DETERMINED to make it abolutely as accurate as possible. What I don't understand is how Trumpeter got so much of it grotesquely wrong. Anyway, thanks for your comments. I sure hope you find my feature useful - from what I've seen the 1:700 from Trumpeter is just a scaled down version of the 1:350 kit, including everything that's wrong with the big one!

JUL 08, 2008 - 05:36 AM

Hi Rui

Well, well, well. I used to be a graphic designer myself as well. And a copywriter. Hence what I hope is a deal of professionalism in my SBS guide.

The whole project spanned two years. I didn't dare start another model in all that time, knowing it would simply delay completion and possibly I would lose my motivation. Sometimes it was very hard to keep going - the progress when doing the armament and the air group seemed so slow. I really had to force myself to keep going.

Thanks for the advice on using Clearcoat on the decals. Actually, that is what I did use, in order to soften the decals so they would lay close on the curved fuselage sides, to get them to stick, and to try and dull them down. All the planes were matt varnished as well, but that still didn't kill the decal edge reflection.

You can see some of my 1:700 stuff at: LINK If you select my name from the top of the menu on the left you can see all my galleries.

By the way, the 1:700 Trumpeter Lexington looks like just a scaled-down version of the 1:350 version, including everything that is wrong and inaccurate. So please, please, do use all the research I did to get it right. I look forward to seeing the result!

Regards, Chris

JUL 08, 2008 - 05:48 AM

Jim

Your comments an honour indeed. I have followed your work over the years at Modelwarships.com and you really are the best. Counting the hours is actually a way of giving myelf a sanity check! Which is why to some extent the whole project took me two years from start to finish.

Regards, Chris

JUL 08, 2008 - 05:53 AM

Thanks for taking time to answer to my questions!

I have the 1/700 Trumpeter model, for Coral Sea fit, so I guess you have done all the research for me - but still, I have to get the work myself!

Not for now, but for a "near" future (I am currently working on three projects, one a full scratch all in 1/700).

Thanks for the link, and since my memory is better for graphics, than for names, I can say that I had already seen your Sara / Lex duo in MW.

Please keep up - keep your ship models afloat!

Rui

JUL 08, 2008 - 05:57 AM

Are you sure that thing is a model. It looks so real. In some of those photos it looks too real. Nice job. Amazinglly nice job. Great tribute to those who sailed, fought and died on board the original Lady Lex carrier. Nice work.

JUL 11, 2008 - 08:46 AM

Hi Chris,

Sorry no plans on any new 1/350 items.

You could use my YC-728 or 829 for an open ammunition lighter. I have some photos of their use as such.

JUL 15, 2008 - 07:06 AM

Hello Chris:

I just finished reading your build log. Outstanding work and very well written. I have this kit, not sure I want to tackle all the inaccuracies vice just building an OOB kit, but, your work is inspirational and you presented a lot of neat ideas to enhance the kit. I will be referencing your build log when I tackle mine. Thanks for posting and sharing.

FEB 10, 2015 - 08:49 AM

Mark, I doubt Chris will respond as this is a 7 year old tread and Chris last signed in 7 years ago.

FEB 10, 2015 - 09:13 AM

wow, awesome model building.

well worth resurrecting the thread and feature.

FEB 11, 2015 - 09:17 AM

Copyright ©2021 by Chris Smithers. _OPINIONS Model Shipwrights, KitMaker Network, or Silver Star Enterrpises. Images also by copyright holder unless otherwise noted. Opinions expressed are those of the author(s) and not necessarily those of Model Shipwrights. All rights reserved. Originally published on: 2008-07-04 00:00:00. Unique Reads: 23646