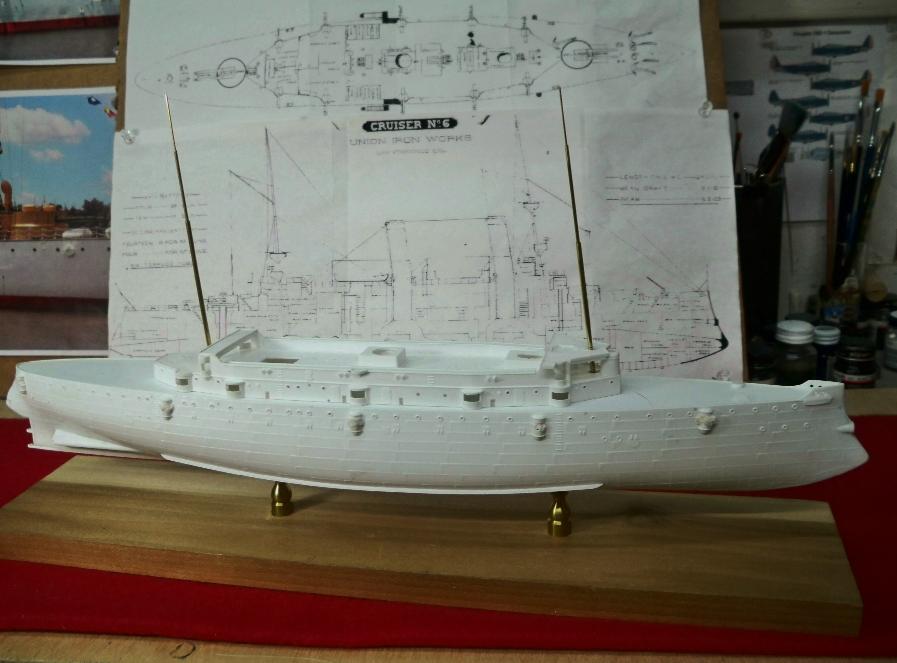

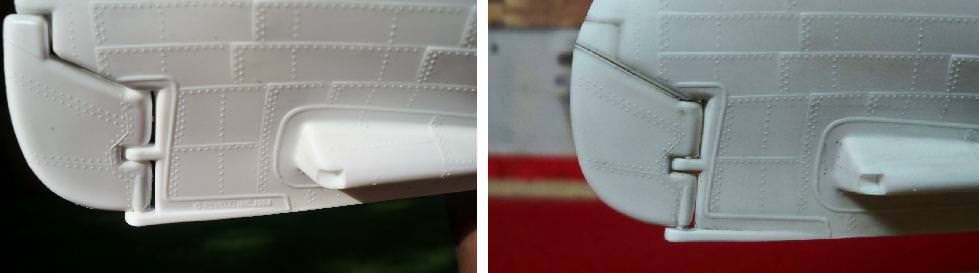

Continuing on with the turrets, a bit more research showed some additional errors.

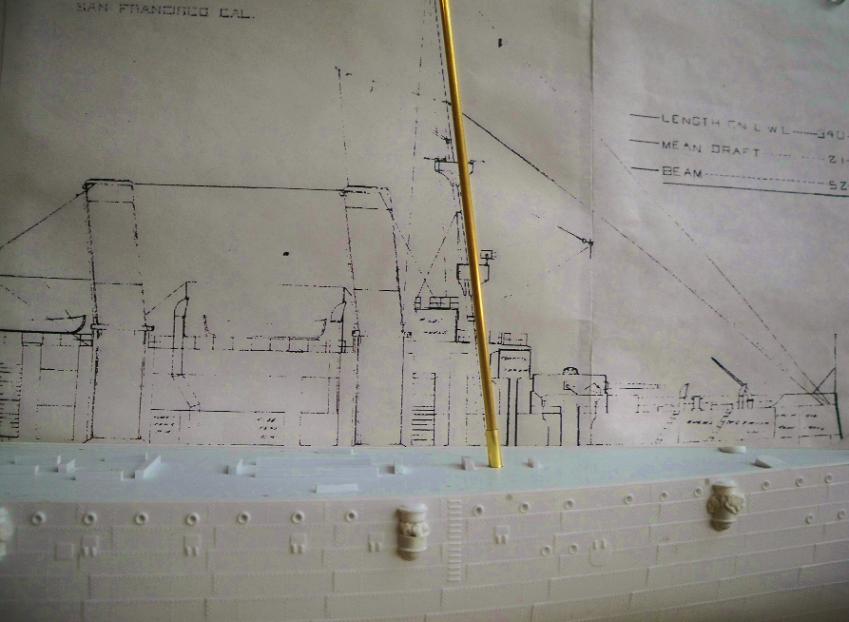

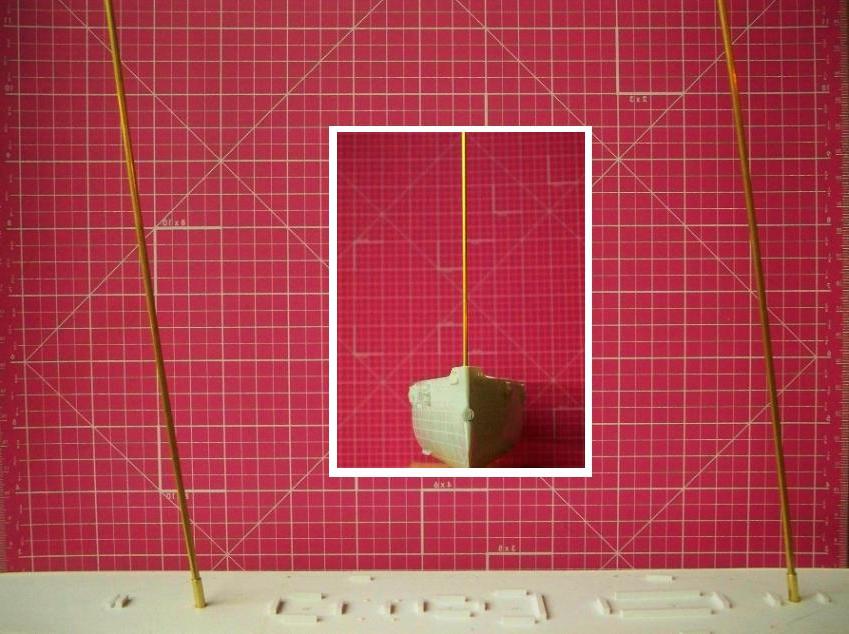

The most serious mistake Revell made with the main turrets was the gun sighting cupolas on the turret roofs. The cupolas are the right size and shape, but they are incorrectly placed. Apparently working from drawings, Revell designers correctly placed the sighting cupola in the center of the each turret as seen from abeam, as in a side-view drawing. However, they must not have had (or not consulted) an overhead view, which would have revealed that there were actually two of these cupolas on each turret roof placed side by side. This is a shame since the Revell parts were nicely rendered, and I couldn’t remove them without damaging them. There were not enough of them to outfit both turrets anyway. An alternative I considered was to resin cast copies and replace the originals, but resin casting is an expensive, messy, and time consuming process I only resort to if I can’t solve the problem in any other way. So I went trolling through my spare parts boxes to find something suitable. The parts boxes yielded nothing, but I finally found a combination that worked: vent tops (parts B-19) form my in-progress Tamiya 1/350 New Jersey were an excellent match for the size and shape of the cupola tops, although I did have to remove them from the half-built battleship (snif)

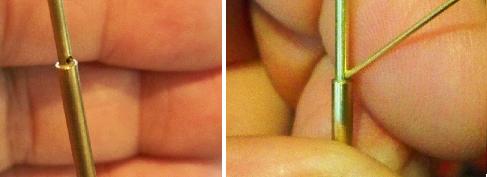

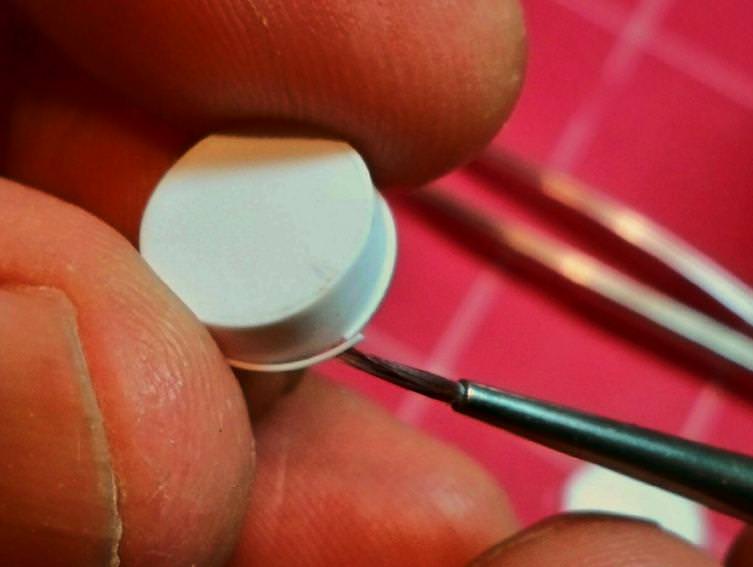

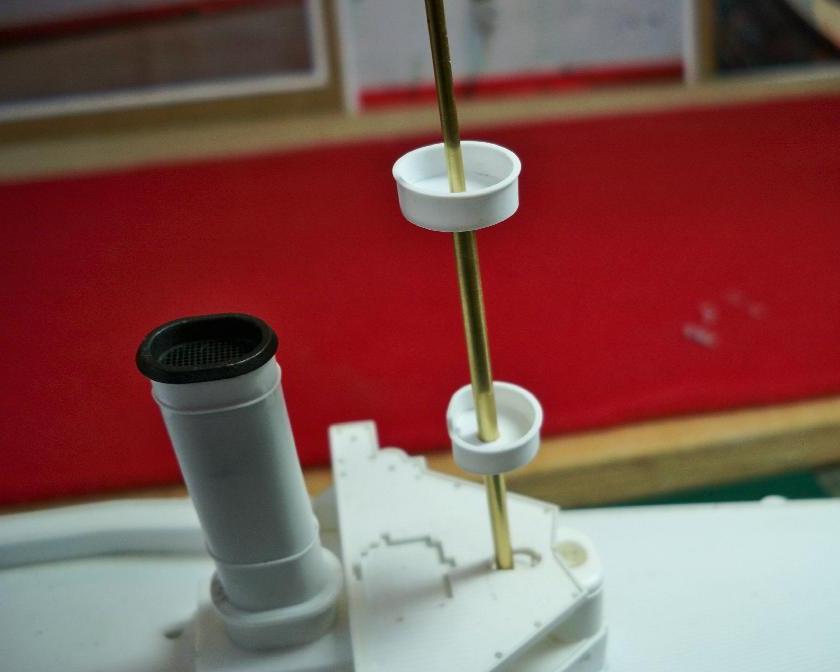

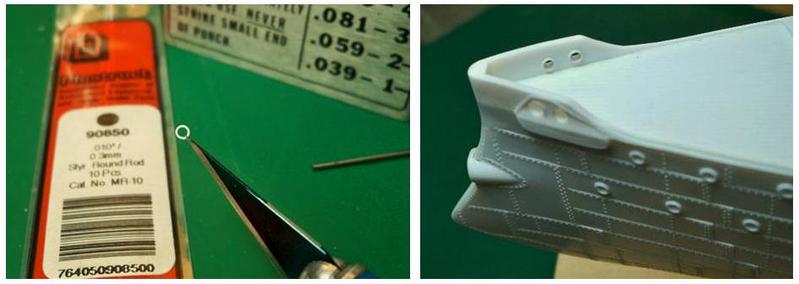

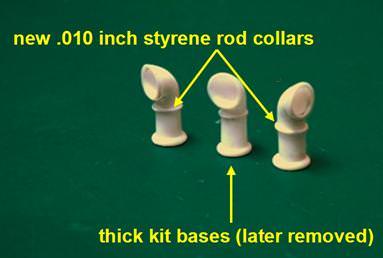

The most serious mistake Revell made with the main turrets was the gun sighting cupolas on the turret roofs. The cupolas are the right size and shape, but they are incorrectly placed. Apparently working from drawings, Revell designers correctly placed the sighting cupola in the center of the each turret as seen from abeam, as in a side-view drawing. However, they must not have had (or not consulted) an overhead view, which would have revealed that there were actually two of these cupolas on each turret roof placed side by side. This is a shame since the Revell parts were nicely rendered, and I couldn’t remove them without damaging them. There were not enough of them to outfit both turrets anyway. An alternative I considered was to resin cast copies and replace the originals, but resin casting is an expensive, messy, and time consuming process I only resort to if I can’t solve the problem in any other way. So I went trolling through my spare parts boxes to find something suitable. The parts boxes yielded nothing, but I finally found a combination that worked: vent tops (parts B-19) form my in-progress Tamiya 1/350 New Jersey were an excellent match for the size and shape of the cupola tops, although I did have to remove them from the half-built battleship (snif)  ... and even they were too short. Further searching yielded the disc retainers for the main gun mounts on the Varyag kit (parts 61). These were almost exactly the same diameter as the Tamiya parts, and together they brought the new cupolas to the correct height. A further advantage of this solution was that the slight mismatch between the parts left a visible horizontal line on each cupola which neatly replicates the sighting apertures missing from the original Revell cupolas.

... and even they were too short. Further searching yielded the disc retainers for the main gun mounts on the Varyag kit (parts 61). These were almost exactly the same diameter as the Tamiya parts, and together they brought the new cupolas to the correct height. A further advantage of this solution was that the slight mismatch between the parts left a visible horizontal line on each cupola which neatly replicates the sighting apertures missing from the original Revell cupolas.

Before setting in those cool B & D turned brass barrels, there was one more detail; relocating the little dome shaped vents on the turret tops. For some reason Revell had placed these forward of the cupolas, but the Booklet of General Plans drawings and photos show these to have been behind them, so I replaced them with plastic discs and put them in their correct locations. These small vents are depicted in the kit as domes, but the few images I was able to find showing this area appear to indicate that the round openings actually had small flat covers which were sometimes (as when in port) removed so that temporary cowl vents could be fitted—without forced air those enclosed steel turrets must have been like ovens!

The turrets look better after all this, but even with with the changes they still look pretty plain. I'll affix photoetch toe rails to the roofs later, and no doubt there is additional detail I could add, but close up pictures are hard to come by. I had some great photos of the preserved ship that I thought would provide guidance, but it turns out the original 8 inch turrets were removed before World War One; the ones there now are replicas added in the 1950s when the ship became a museum! So until and unless I get some new information, I'll leave them as they are.

]

] [

[