Thank you guys, I appreciate your kind words!

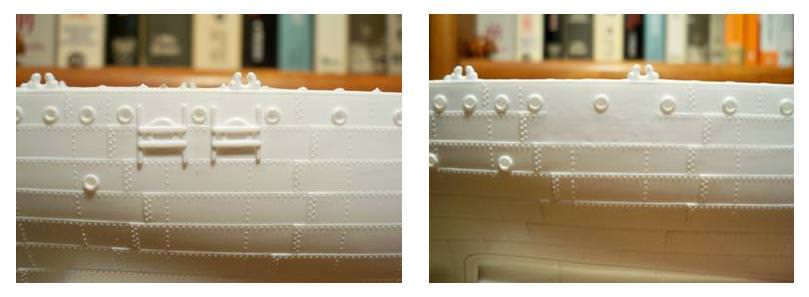

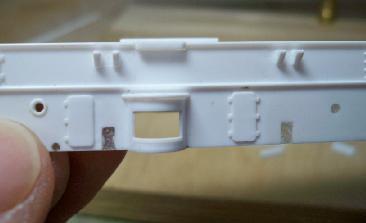

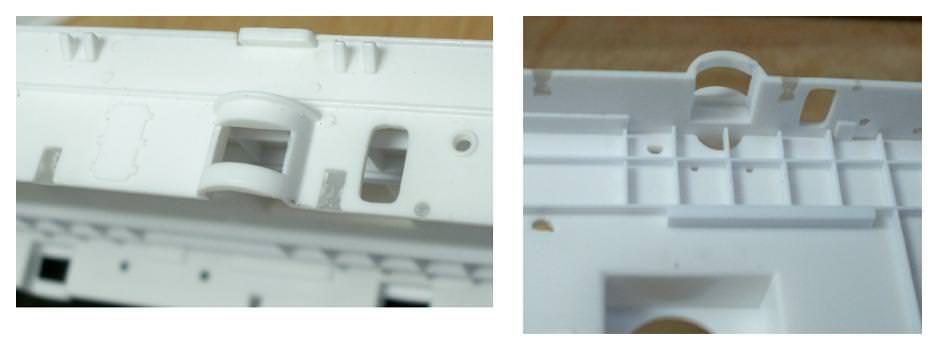

Having completed the boats in the racks, I set about fitting the boats which hung directly from their davits. The two small cutters (“lifeboats” according to the Revell instructions) located on the superstructure between the racked boats came first. I had previously improved them with new keels, floorboards, gunwales, and oars. In addition, they now received new brass wire davits to replace the kit parts.

Photoetch pulley blocks to mount the boats to them came from an old Gold Medal Models Yamato set; they are tiny, but they are still fairly resilient. I set the pulley blocks securely into the boats with cyanoacrylate. These little guys would bear the whole weight of the cutters, so the connections had to be strong!

After the new davits were painted up and mounted to the superstructure sides, I attached the completed portside cutter by the pulleys with drops of cyano. There wasn’t much surface area to work with here, so I just did the best that I could; in the end, the bonds holding the boats to the davits are secure but very fragile. I also added some chain strongbacks and lateral supports between the little davits using the trusty l’Arsenal photoetch chains. Bent into gentle curves to give them a natural-looking hang, they are secured in place with Gator Glue.

The starboard side is a little different. One disadvantage I had noticed with the portside boat mounting is that it obscures the searchlight tower I had expended so much effort to scratchbuild. On the empty starboard side, though, the view of the tower remains unobstructed. I liked this, so I mounted the photoetch pulleys to the davits and attached the lower ends to the davit bases, as if the crew had taken the cutter out on some errand.

Meanwhile, the port cutter is standing by!