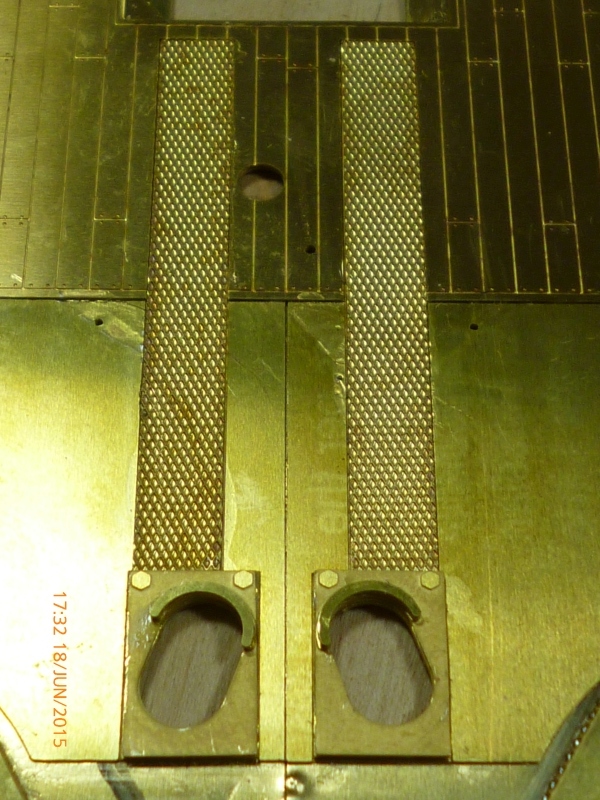

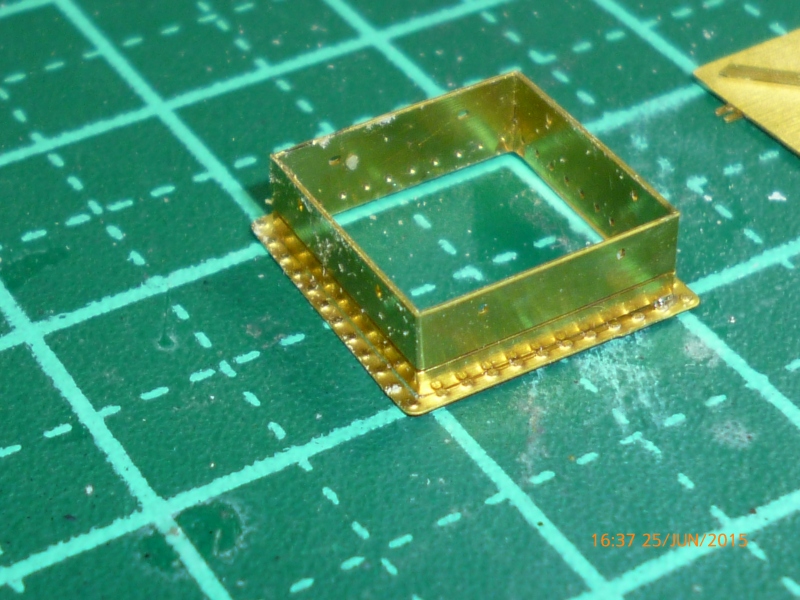

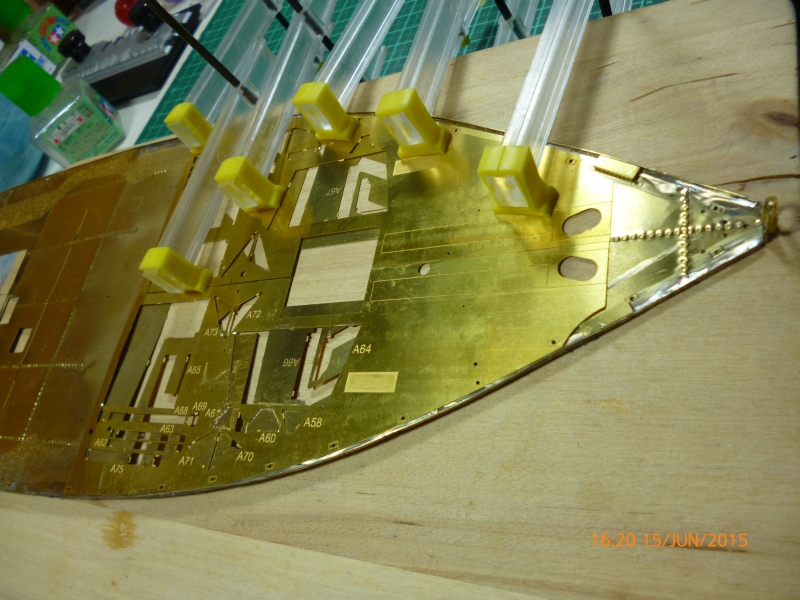

Last few days have all be about building up the foredeck with various layers of PE to replicate the real thing.. (I hope!)

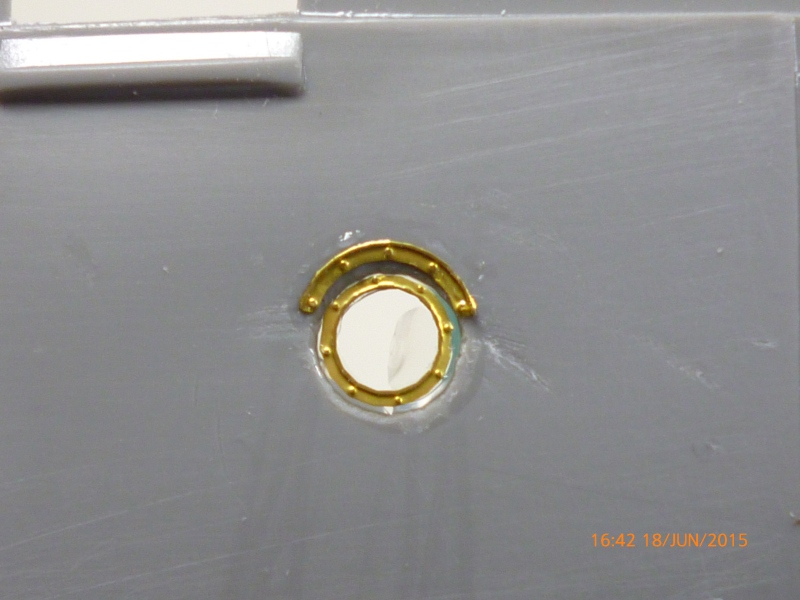

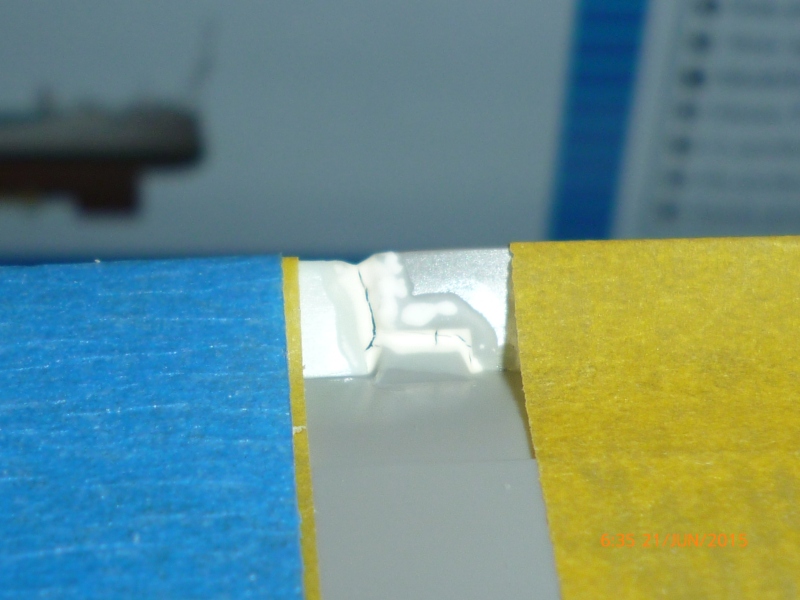

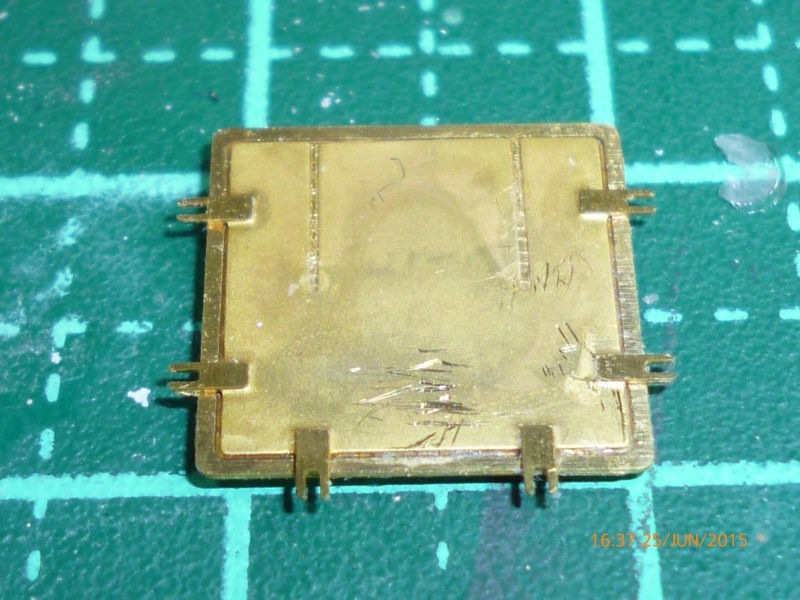

Here is the first layer..

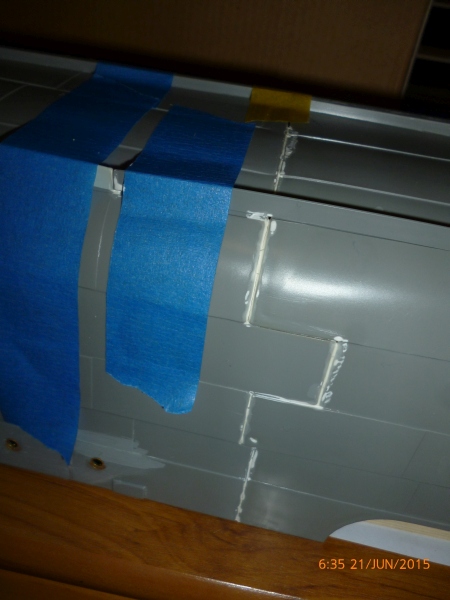

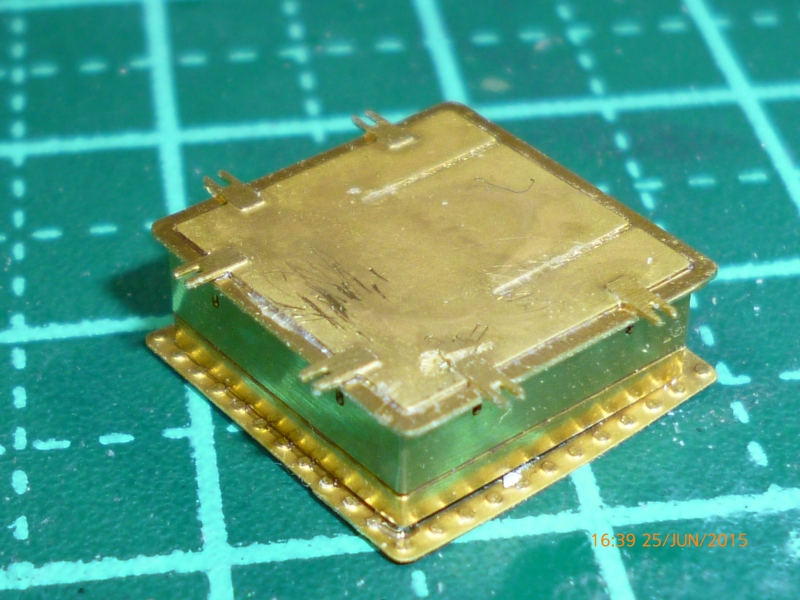

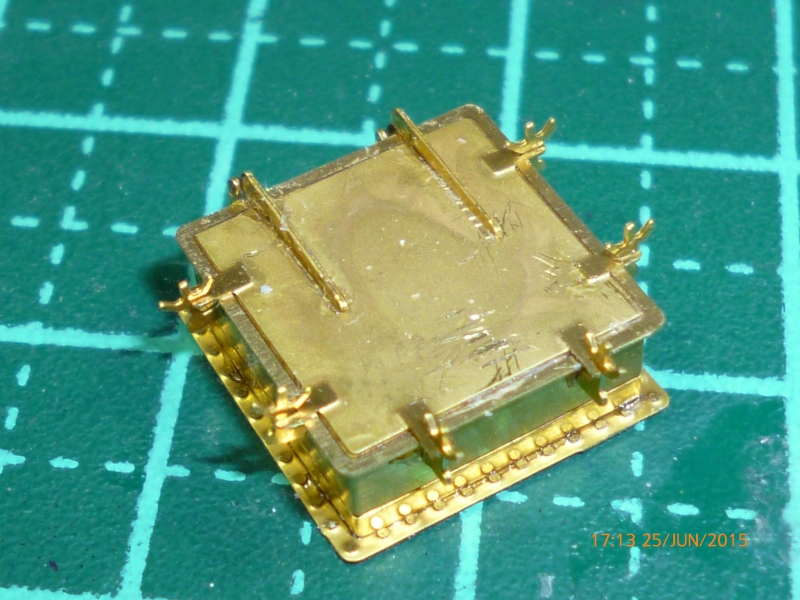

The clamps hopefully hold the parts in place while the CS glue sets after it is applied. Even though accelerator is used there is always some that needs to dry.

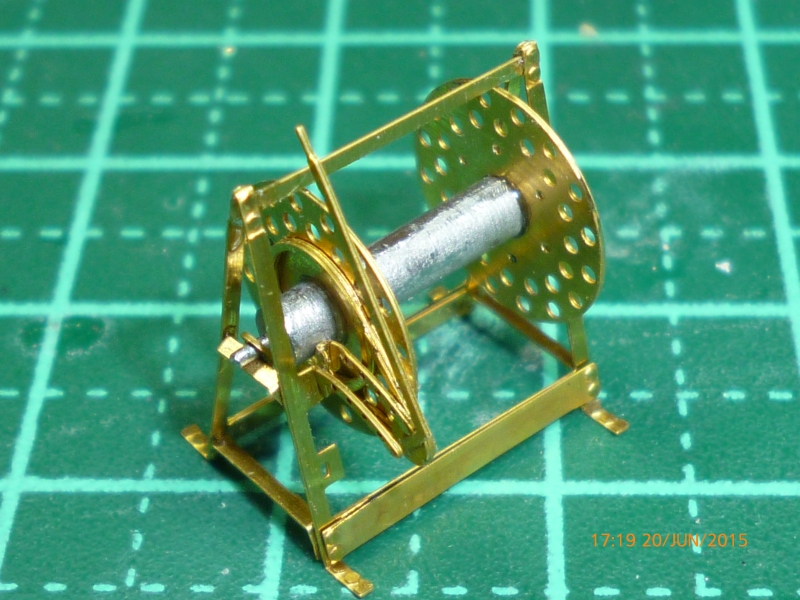

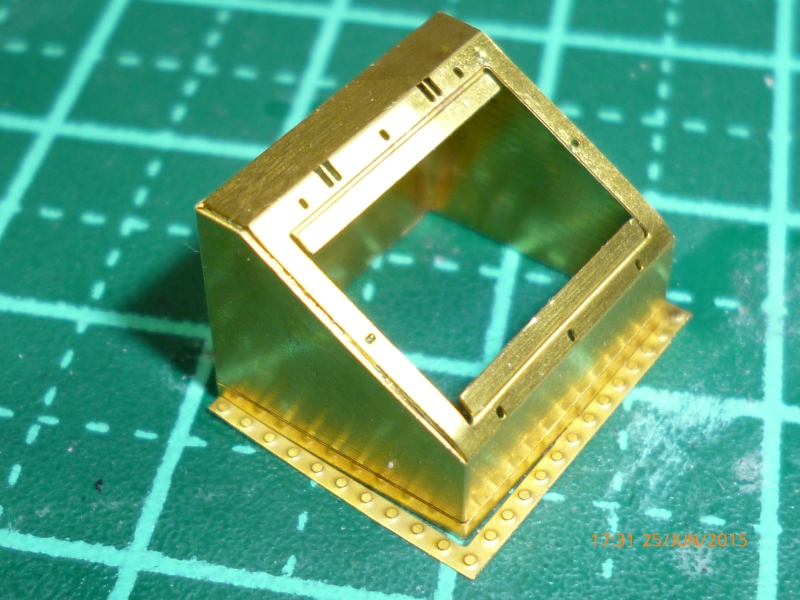

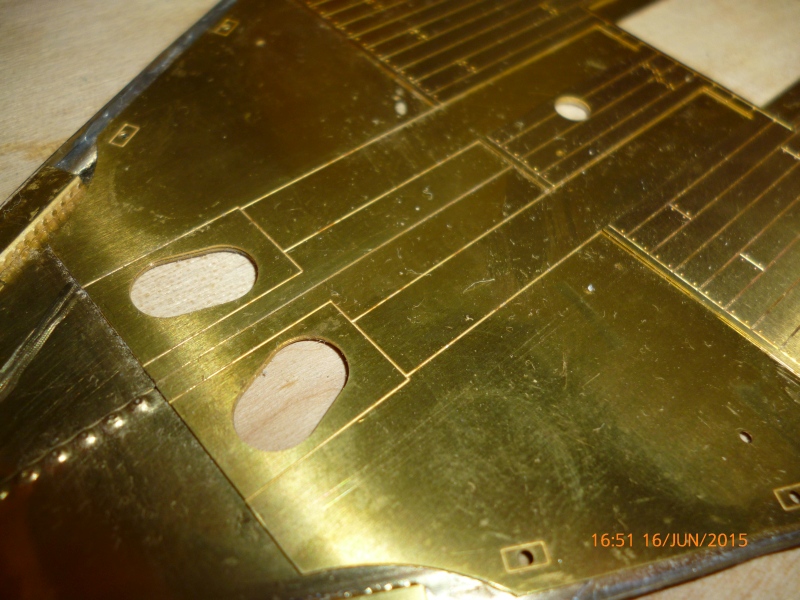

Next up we have the layers finished for the foredeck..

I am not sure what I am going to do to the wooden part yet as I have some wooden deck sheeting I bought with the exact plank width I need for this deck. But then there are others who say there was no wooden deck on the corvettes.. I have no photographic evidence either way yet.

From other's information the GLS deck is accurate and there were wooden decks on these Corvettes.

That's it for now

Cheers

Warren